The FOSENSE gas density monitors provide reliable warnings against dangerously low gas levels, even under extreme ambient conditions. Electrical switch contact raises an alarm signal to the monitoring system,when the gas density drops below defined levels due to leakage.

Via the on-site display, the pressure based on 20 °C [68 °F] can be read directly on the instrument.

With regard to switchgear safety, asset protection and environmental protection, it is common to perform functional checks on a regular basis. Article 5 of EU regulation No. 517/2014 on fluorinated greenhouse gases, provides for checking of the leakage detection system at least every 6 years if it contains > 22 kg SF6 gas. According to the Chinese JB/T0549-2006 standard, the calibration cycle after the product is put into use generally does not exceed one year.

With the help of the firmly welded calibration valve, the gas density monitor can be shut off from the process and recalibrated without having to disassemble it. This not only reduces maintenance time but also minimises the risks of SF6 gas emissions and potential leakages during recommissioning.

When connecting a recalibration instrument (model V3-P) to the valve, the gas density monitor is automatically disconnected from the gas compartment and a valve can be performed. Following the recalibration process, the recalibration instrument can then be disconnected from the valve and the connection to the gas compartment is re-established automatically.

The valve is also available as a retrofit solution for gas density monitors already installed in the field, as model V3-F, and can be mounted between the gas compartment and gas density monitor. They can provide multiple solutions to support new substations and the intelligent transformation of existing substations.

Rang:-0.1∼0.9MPa(customized)

Contact type:Magnetically assisted electrical contact switch80%Ag20%Ni .Gold plating of contacts

Accuracy specifications: ±1 %/±1.6 % at an ambient temperature of +20 °C;±2.5 % at an ambient temperature of -40℃ ∼ +60 °C

Insulation properties:Insulation resistance>100M(500V DC);AC withstand voltage≥2kV,50/60Hz 1min

Weather protection:IP66

Contact electrical parameters:≤30W/50VA;≤1A;≤220VDC/380VAC

Ambient temperature:-40℃∼+60℃,Permissible humidity≤95%RH

Shock resistant:≤50g(Oil-filled type)OR≤30g(Non-oil-filled type)

Pressure element's gas-tight: Leakage rate ≤ 1×10-9 Pa·m3 /s(Helium mass spectrometry)

Vibration resistance:20m/s2

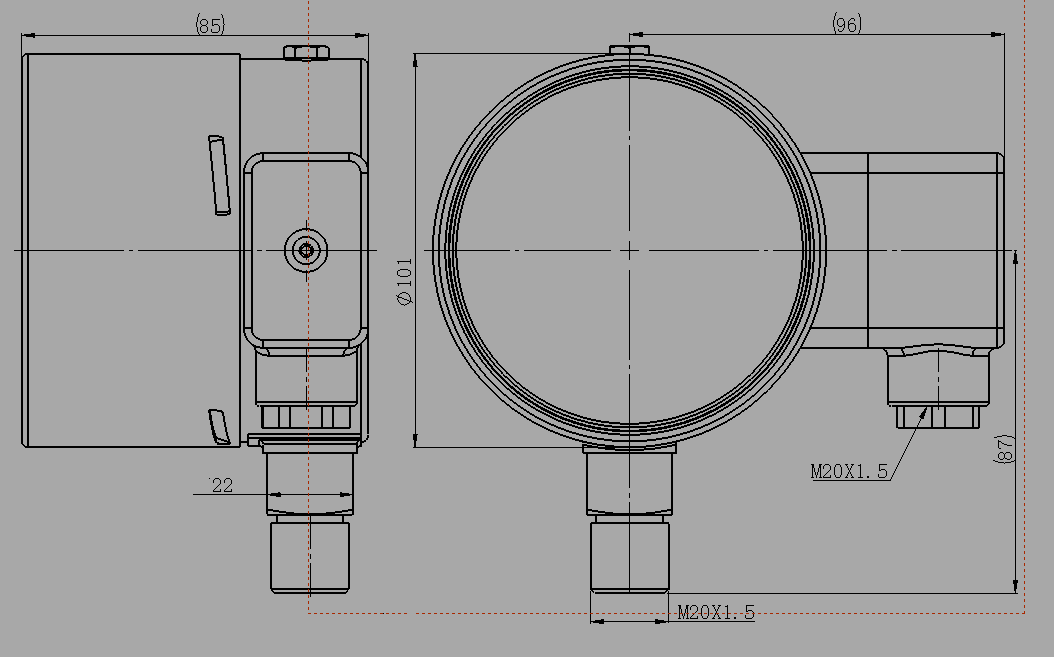

Process connection:M20×1.5, G1/2 (customized)

Weight:≈1.2 kg

X

X