Applications

Gas density is a crucial operating parameter for high-voltage plants. If the required gas density is depressurized, safe operation of the plant cannot be guaranteed.

The FOSENSE gas density monitors provide reliable warnings against dangerously low gas levels, even under extreme ambient conditions. In addition to V2-103/T remote density relay with Modbus output function, which includes high-precision sensors and evaluation electronics.

Via the on-site display, the pressure based on 20℃[68 °F] can be read directly on the FOSENSE gas density monitor. With the integrated switch contacts, simple switching tasks can be realised quickly and without complication. The integrated 4∼20 mA or Modbus® sensors integrated or attached to the instrument enable remote monitoring of the plant.

The measured data for pressure, temperature and gas density are transmitted using the standardised Modbus® RTU protocol. The model V2-103/T can also be configured for alternative gases consisting of N2, CF4, O2, CO2, etc.

The analogue version of the V2-103/T uses the proven technology of the 4∼20 mA analogue signal and outputs the absolute pressure at 20℃[68 °F] or the gas density(g/l) for SF6 gas as an analogue signal.

The data storage enables trend analysis to be carried out, so that critical SF6/or mixed gas conditions can be predicted and rectified in time. By using gas density relay, real-time data of SF6 gas density can be remotely transmitted, achieving online remote monitoring,which is designed to monitor high-voltage systems. They can provide multiple solutions to support new substations and the intelligent transformation of existing substations.

Rang:-0.1∼0.9MPa(customized)

Contact type:Magnetically assisted electrical contact switch80%Ag20%Ni .Gold plating of contacts

Accuracy specifications: ±1%/±1.6% at an ambient temperature of +20℃;±2.5 % at an ambient temperature of -40℃∼+60℃

Insulation properties:Insulation resistance>100M(500V DC);AC withstand voltage≥2kV,50/60Hz 1min

Weather protection:IP66

Contact electrical parameters:≤30W/50VA;≤1A;≤220VDC/380VAC

Ambient temperature:-40℃∼+60℃,Permissible humidity≤95%RH

Shock resistant:≤50g(Oil-filled type)OR≤30g(Non-oil-filled type)

Pressure element's gas-tight: Leakage rate ≤ 1×10-9 Pa·m3 /s(Helium mass spectrometry)

Vibration resistance:20m/s2

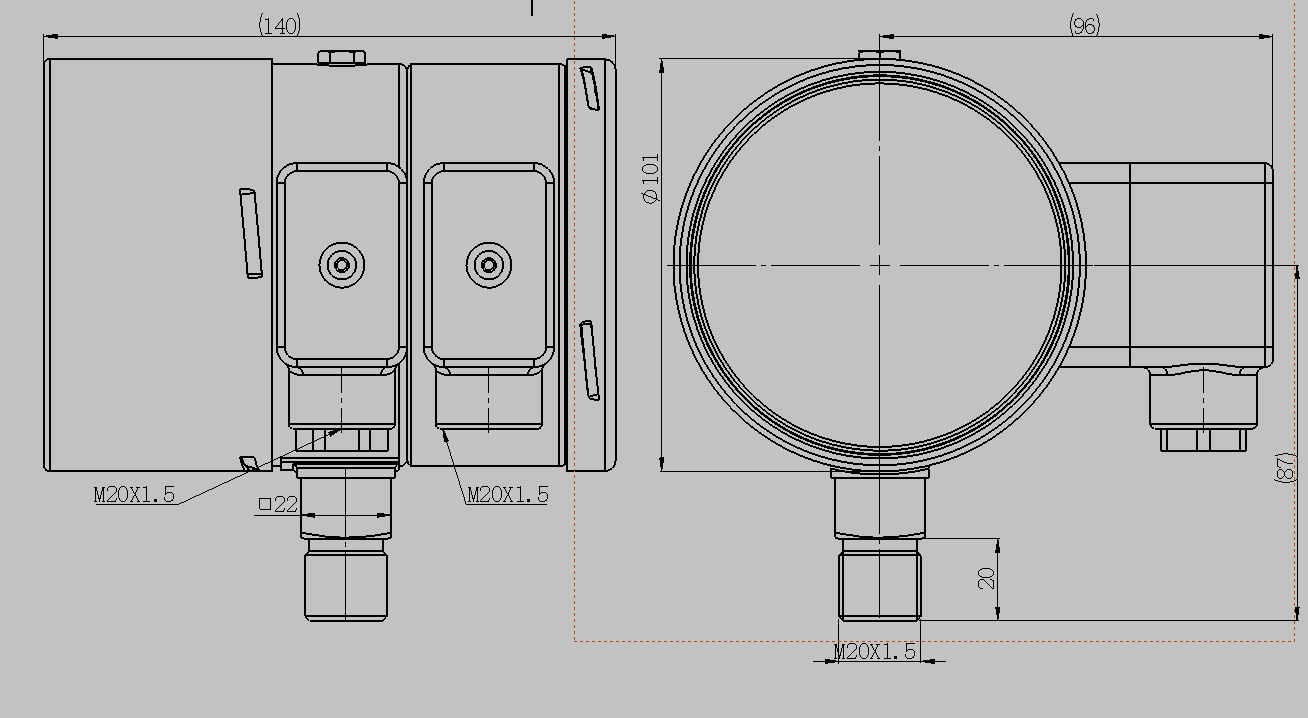

Process connection:M20×1.5, G1/2 (customized)

Weight:≈1.2 kg

Operating voltage:24VDC

Power consumption:≤2W

Communication method:RS485,4∼20mA,IEC61850,Wireless communication(LoRa)

EMC tests:IEC61000-4-2:class4(15KV) IEC61000-4-3:class3(10V/m)

IEC61000-4-4:class4(4KV) IEC61000-4-5:class4(±4KV)

IEC61000-4-6:class3(10V) IEC61000-4-8:class5(100A/m)

IEC61000-4-9:class5 IEC61000-4-10:class5

IEC61000-4-11:60%Ut

X

X