Medium and high-voltage switchgear

Test connection from stainless steel pipe/or copper pipe for testing other parameters

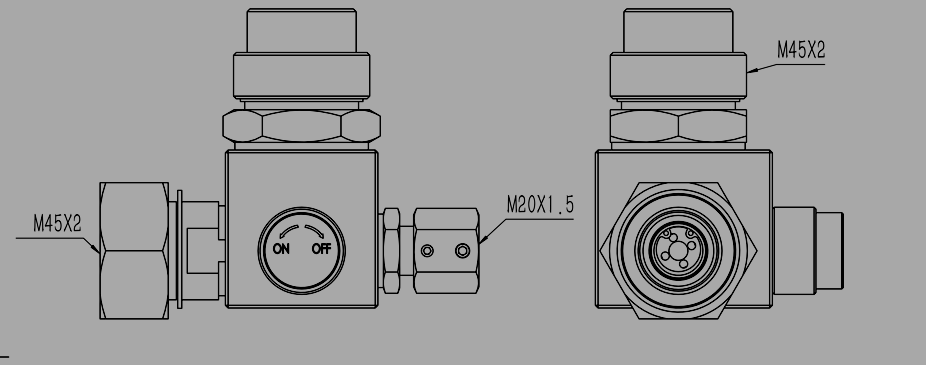

This V3-F valve is used for retrofitting in order to be able to calibrate an existing gas density monitor.

The model V3-F is fitted between the gas tank and the gas density monitor. With the help of the calibration valve, the gas density monitor can be shut off from the process and recalibrated without having to disassemble it. This not only reduces maintenance time but also minimises the risks of SF6 gas emissions and potential leakages during recommissioning.

With regard to switchgear safety, asset protection and environmental protection, it is common to perform functional checks of a gas density monitor on a regular basis. Article 5 of EU regulation No. 517/2014 on fluorinated greenhouse gases, provides for checking of the leakage detection system at least every 6 years if it contains > 22 kg SF6 gas.

According to the Chinese JB/T10549-2006 standard, the calibration cycle after the product is put into use generally does not exceed one year.

Raw material:Aluminium/Aldary/Stainless steel

Nominal diameter:6,8,12mm(Medium voltage equipment) 20mm(High voltage equipment)

Surface treatment:Aluminium:Oxidation treatment;Aldary:No processing;AISI304Stainless steel:No processing

Operation Temperature:-40℃∼+60℃

Pressure element's gas-tight: Leakage rate ≤ 1×10-9 Pa·m3 /s(Helium mass spectrometry)

X

X