Permanent monitoring

In order to prevent system failures in switchgear and network outages,the permanent monitoring of the gas density is essential.

The V2-T transmitter calculates the current gas density from the pressure and temperature using a complex virial equation in the transmitter's powerful microprocessor. Changes in pressure resulting from thermal effects will be compensated by this and will not affect the output value.

Modbus® fieldbus

The RS-485 interface communicates using the Modbus® RTU protocol. The instrument's output parameters and their units can be configured and read according to requirements. The V2-T can be configured later by the customer for each defined SF6 gas mixture with N2 or CF4.

Signal stability

Due to its high long-term stability,the V2-T density transmitter is maintenance-free and requires no recalibration.

The EMC characteristics fulfil the IEC 61000-4-2 through to IEC 61000-4-6 standards and guarantee an interference-free data output.

Rang:0∼1.0MPa(customized)

Accuracy specifications:±1.0 %at an ambient temperature of +20℃;±2.5 % at an ambient temperature of -40℃ ∼ +60℃(SF6 is a gas)

Weather protection:IP65

Ambient temperature:-40℃∼+60℃,Permissible humidity≤95%RH

Pressure element's gas-tight:Leakage rate ≤ 1×10-9 Pa·m3 /s(Helium mass spectrometry)

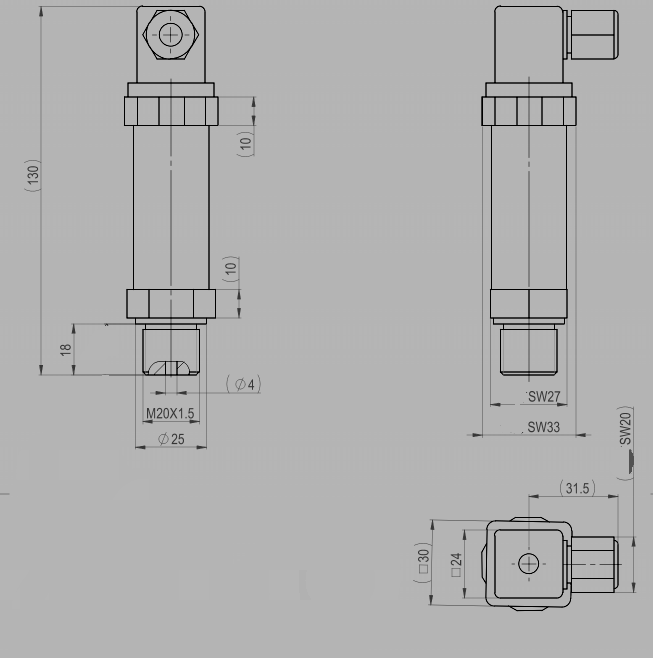

Process connection:M20×1.5(customized)

Power consumption:≤2W

Communication method:RS485(Modbus RTU),4∼20mA,IEC61850,Wireless communication(LoRa)

EMC tests:IEC61000-4-2:class4(15KV) IEC61000-4-3:class3(10V/m)

IEC61000-4-4:class4(4KV) IEC61000-4-5:class4(±4KV)

IEC61000-4-6:class3(10V) IEC61000-4-8:class5(100A/m)

IEC61000-4-9:class5 IEC61000-4-10:class5

IEC61000-4-11:60%Ut

X

X