Overview

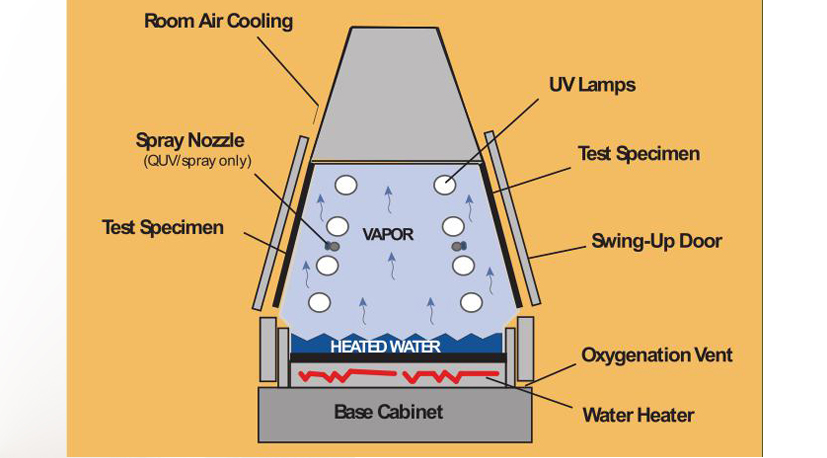

UV Accelerated Weathering Tester, To simulate the destructive effect for materials from sunshine, moisture and temperature. Materials aging including fade, loss of gloss, low intensity, cracking, peeling, pulverization, and oxidation, etc. UV accelerated weathering tester simulate sunshine, condensation and natural moisture condition, and samples stay inside this condition can be equaled to stay outdoor for several months or years.

The Fluorescent Ultra-Violet Lamp of UV aging chamber can reappear the effect of sunshine, Condensation and water spray system can reappear the effect of rain and dew.

Standards

|

ASTM G 153, ASTM G 154, ASTM D 4329, ASTM D 4799 ASTM D 4587, ASTM D1148, SAE J2020, ISO 4892, etc |

Structure

Features

Key Specifications

|

Model |

M025 |

|

|

Control Type |

Touch Screen Control(TEMI880) |

|

|

Test chamber size |

450×1170×500mm |

|

|

Outside chamber size |

550×1300×1480mm |

|

|

Machine material |

Totally SUS 304 stainless steel |

|

|

Sample holder |

Aluminium alloy |

|

|

Temperature range |

RT+10℃~70℃ |

|

|

Humidity range |

≥90%RH |

|

|

Temperature uniformity |

±1℃ |

|

|

Temperature fluctuation |

±0.5℃ |

|

|

Interior center distance of lamp |

70mm |

|

|

Irradiance |

Within 1.0W/m2 adjustable |

|

|

Light, condensation and spray cycle |

Adjustable |

|

|

Lamp |

L=1200/40W, 8 pcs(UVA/UVB with life time above 1600h) |

|

|

Standard sample size |

75×290mm |

|

|

Water bath depth |

25mm auto control |

|

|

Effective radiation area |

900×210mm |

|

|

Test time |

0~999 Hours |

|

|

Irradiation blackboard temperature |

50℃~70℃ |

|

|

Standard sample holder |

24 pcs |

|

|

Ultraviolet Wavelength |

UVA 340 |

315-400nm |

|

|

UVB 313 |

280-315nm |

|

Power Supply |

AC 220V 50/60HZ 5KW |

|

|

Dimension(L×W×H) |

1300×550×1480mm |

|

|

Weight |

150 kg |

|

Material to be Tested

UV Accelerated Weathering Tester M025, It is widely used in coatings, inks, paints, resins, plastics, printing and packaging, adhesives, automobile, motorcycle industry, cosmetics, metals, electronics, electroplating, medicine, etc.

Demonstration Video

X

X