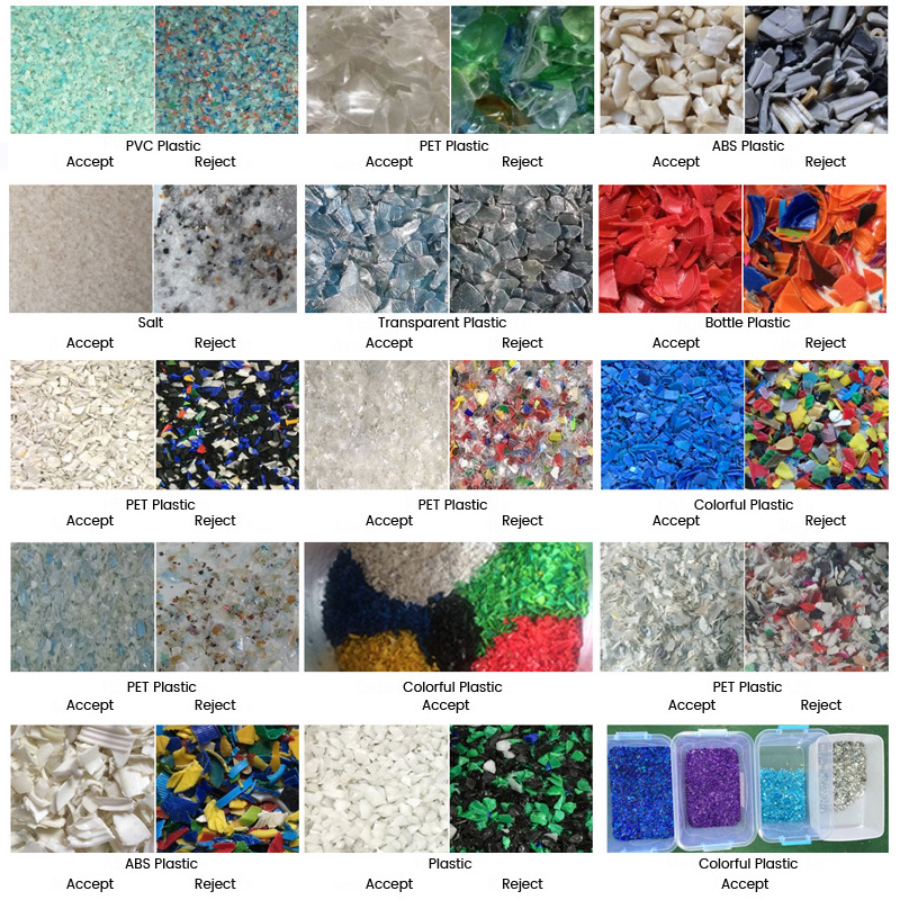

Recycling plastic sorting machine is suitable for all kinds of plastics flakes, recycled plastics color sorter, also can be used to choose the white, yellow, black, red, green, blue and other colors of color selection. Can also apply to the PC, ABS, PA, PS, PET and PP separation of particles or material, etc.

Recycling plastic colour sorter is renowned worldwide for supplying industry leading optical sorting solutions to the food and non-food industries and has been at the forefront of pioneering optical sorting technologies for many years.

Through substantial investment in research and development, we have developed state-of-the-art technology that allows recycle to maximize the recovery and purity of their recycled plastics and reduce the amount of reusable material that ends up in landfill every year.

We are active in many areas of plastic recycling from the packaging, construction, electronic/electrical (WEEE), End-of-Life vehicle (ELV) to the petrochemical industries, providing solutions to the most difficult and challenging applications.

Recycled plastic color sorting machine is suitable for all kinds of plastics, recycled plastics separation, also can be used to choose the white, yellow, black, red, green, blue and other colors of color selection. Can also apply to the PC, ABS, PA, PS, PET and PP separation of particles or material, etc.

We are renowned worldwide for supplying industry leading optical sorting solutions that maximize not only your processing capacities but also the recovery and purity of your recycled PET (RPET) flakes. Through the removal of unwanted colors, polymer contaminants, metals and foreign materials, recycles can be confident of the highest grade RPET flake with near-pure resin streams.The comprehensive PET sorting portfolio from our company. brings together industry leading sorting technologies providing recycles with dedicated and precise detection systems targeting all major recycling concerns. Using a combination of trans missive and reflective sorting technologies, our flake sorters are equipped to target anything from the removal unwanted colors, metals and foreign materials to the removal of same-in-colour polymer contaminants such as PVC, PP and PE.

The flake sorters can also be tailored into a full turnkey solution including not only the optical sorting equipment but also all auxiliary equipment in addition to valuable automation, engineering and service expertise. Turn to the first choice supplier of PET sorting technology to maximize your processing capacities, recovery and purity today.

HDPE is sourced from packaging materials; milk bottles, bottle caps, detergent and shampoo bottles. To obtain a finished sort of quality and purity, a processor needs to obtain near-pure resin streams. This is achieved through the removal of defects and foreign materials.The range of optical sorters meet this requirement. Equipped with the latest in technological advances, typical defects such as coloured PE and PP, packaging labels, aluminium and wood is effectively detected and removed.

Pellet Sorting Solutions tailored to suit your needs

During the manufacturing of plastic resin, the product often develops various defects. To obtain a finish sort of quality and purity, a processor needs to remove these challenging defects and foreign materials.The range meet this requirement. It is equipped with the latest in technology; custom-built, high definition cameras, shape detection and high-speed ejectors. Typical and challenging defects such as minute spot defects, discoloration, misshapen pellets and clumps can be effectively removed.

UPVC window off-cuts are sourced from double-glazing window fabricators, whereas post-consumer product comes from demolition of properties. This presents many challenges in sorting, including the isolation of black rubber seal fragments and, more importantly, the removal of white silicon, nylon and rubber from white UPVC regrind.our optical sorters is the ideal sorting equipment for plastic processors and recycles of white, brown and coloured. Equipped with the latest in technological advances, the range effectively detects these as defects and foreign materials, and efficiently removes them.

With the core sorting technology ,Our plastic color sorter can sort anything.Our plastic color sorting machine can be widely used in sorting PET bottle flakes,HDPE/LDPE bottle flakes,PE/PP bottle caps and ABS/PS/PC engineering plastic and so on.

Advantages of color sorter

1. Intelligent Infrared distinction system. Every chute with four camera positions,which can locate the infrared device and high speed super high definition true color 5400*3CCD Sensor, adopting the far infrared technology,supported by the imported high capacity high speed image processing chips, it can ensure the high speed high definition detecting the defect in complicated environments.

2.30000+ plastic and granules detecting every second. Computing updating, TI high proformance chips, accurately discover the quality of the sorting products. Take plastic for example, every second 30000+ plastic granules detecting, accurately remove variety defects. The sorting accuracy are much higher, processing capability are much stronger. It ensure the variety of defects, tiny spot, light trace are easily discovered. The wisdom helps us “what you see is what you get”.

3.Illimitable sorting possibilities, start by “one button”pressuring. Hundred of sorting profiles can be saved in machine machine, for the variety products for sorting, illimitable sorting possibilities, “one button”start, “one button”profiles exchange, it can bring the illimitable sorting result for seperation the agricultural products.

4.Shadowless cold light source,automatic adjustable Extremely long life, low energy consumption intelligent shadowless cold light source, orthogonal spectrum technology, make the image more visiable, more accuracy detection; the output luminance of light source are automatically adjustable, it make the lights more stable with high quality. It is fully appliable for the camera to see and detect.

5.Global leading electromagnetic levitation solenoid valve. Global leading electromagnetic levitation solenoid valve, super high rapid response to the Algorithm results. It can continuously working 12billion+ times, extremely long life, with low air consumption.

6.Newly special super width chute design Special technology chutes, applicable for universal materials, make the transfer more steady, more capacity. Meanwhile there are slot-type and plate-type meeting various demands.

7.Mechnical reconstruction. Reconstrution of the mechnical frame, the main part with special material, balancing whole frame bearing, ensure the machine integrity. Working with the updated mechanism, it strength the base of the ultra-sorting.

8.Intelligent operation System Overall Large Screen HD Operation control panel, 1080P Super high resolution, system more stable, more friendly Human-Machine-Interface panel, which gives high sensitivity instant fast repones in the industrial environment.

| Model |

MPCS-4 |

MPCS-5 |

MPCS-6 |

MPCS-8 |

|

Channels |

256 |

320 |

384 |

512 |

|

Capacity(t/h) |

1.0-2.0 |

1.3-2..3 |

1.6-2.6 |

2.2-3.3 |

|

Power(kw) |

2.2 |

2.6 |

3 |

4 |

|

Voltage(V) |

110-250V/50-60Hz |

110-250V/50-60Hz |

110-250V/50-60Hz |

110-250V/50-60Hz |

|

Sorting accuracy |

99.99% |

99.99% |

99.99% |

99.99% |

|

Rejection rate(bad:good) |

≧10:1 |

≧10:1 |

≧10:1 |

≧10:1 |

|

Dimension(mm) |

1965*1630*2050 |

2225*1290*1710 |

2595*1630*2050 |

3350*1630*2050 |

|

Air consumption(L/M) |

1000-1800 |

1300-2200 |

1500-3000 |

2000-4000 |

|

Weight(kg) |

750 |

880 |

1050 |

1400 |

Remark:we have 16 models for optical sorting plastic,here we just list 4 models for reference.

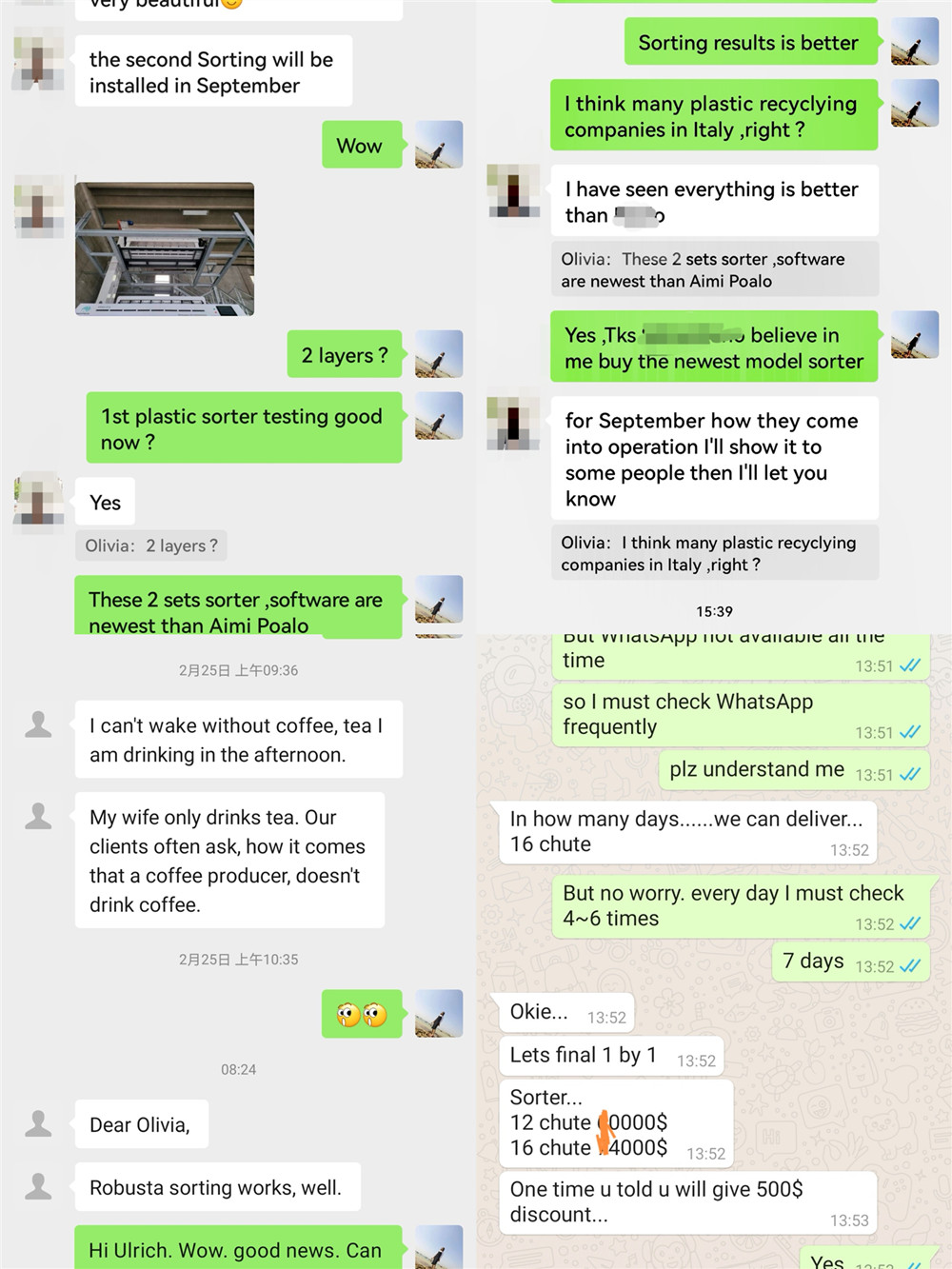

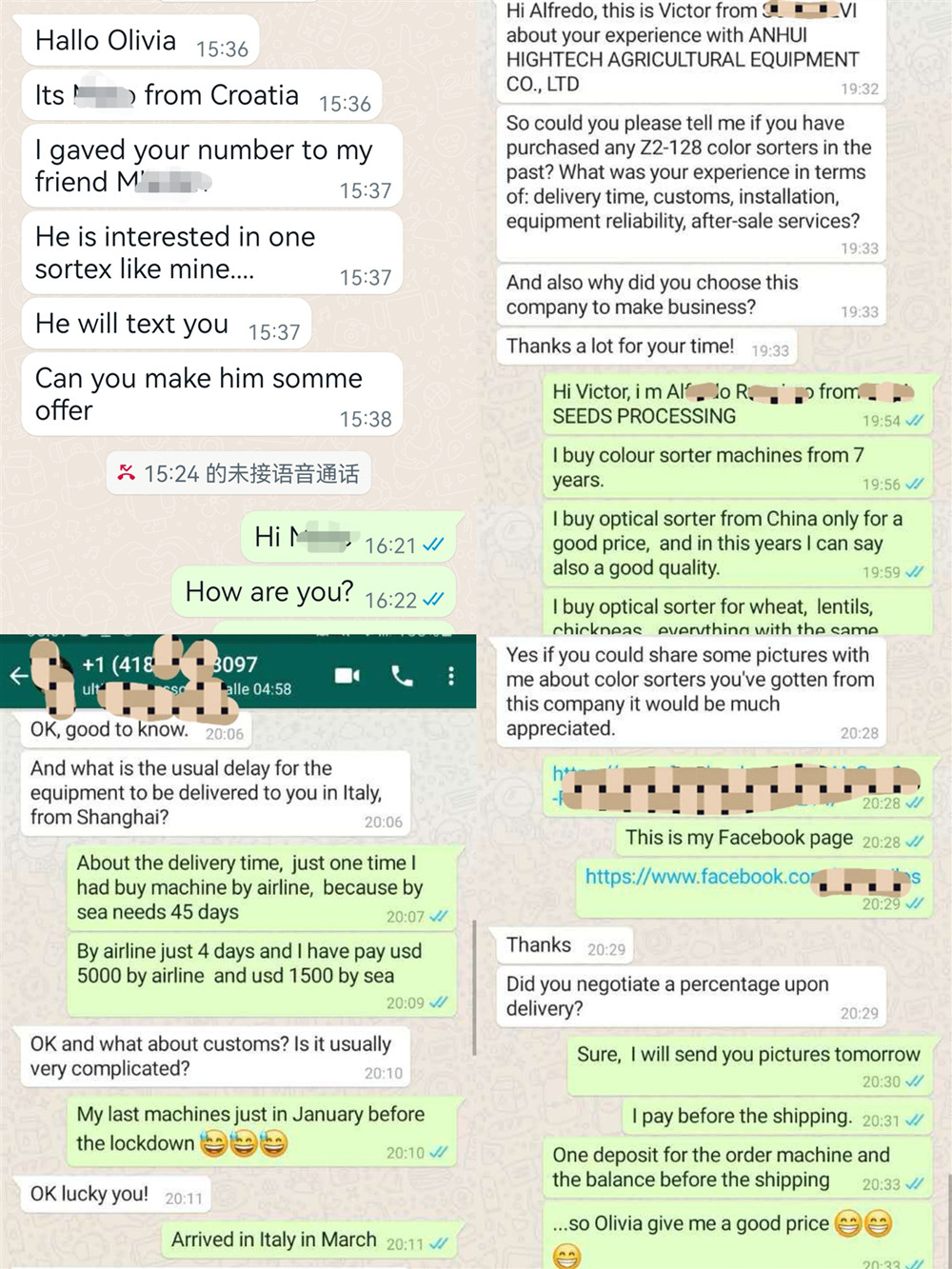

Customer feedback is the driving force behind our progress:

Plywood Case is Suitable for Sea/Road/Air Transport:

1. How to use the machine?

We will supply the Installation instructions and videos for guiding you how to set color sorter.

2. How long about the guarantee period?

Two years. And we supply lifelong software upgrade services for our customers.

3. Can you supply the air compressor, air tank and air filters?

Yes, we can provide above equipments, our standard offer includes color sorter machine with air compressor & air tank & air dryer & air filters.

4. Is oversea service available?

Yes, we will send engineer go abroad when you need it.

5.How to calculate Installation personnel cost?

On condition that customer requires to install, our company would like to send 1 engineer to guide for installation, then customer should to pay the cost, including transaction of engineer’s visa, transportation(air) for go abroad. and accommodation , local transportation and security when the engineer arrived.

6. If you have agent in our country?

We have agent in UK,New Zealand,Italy,Crotia,India, Guatemala,Finland,Malaysia,Bangladesh,Pakistan,Nigeria,Ukraine,Nicaragua etc. and we can provide after-sales service in your Country.

We have many installation cases and working videos.Please contact us freely if you need.

X

X