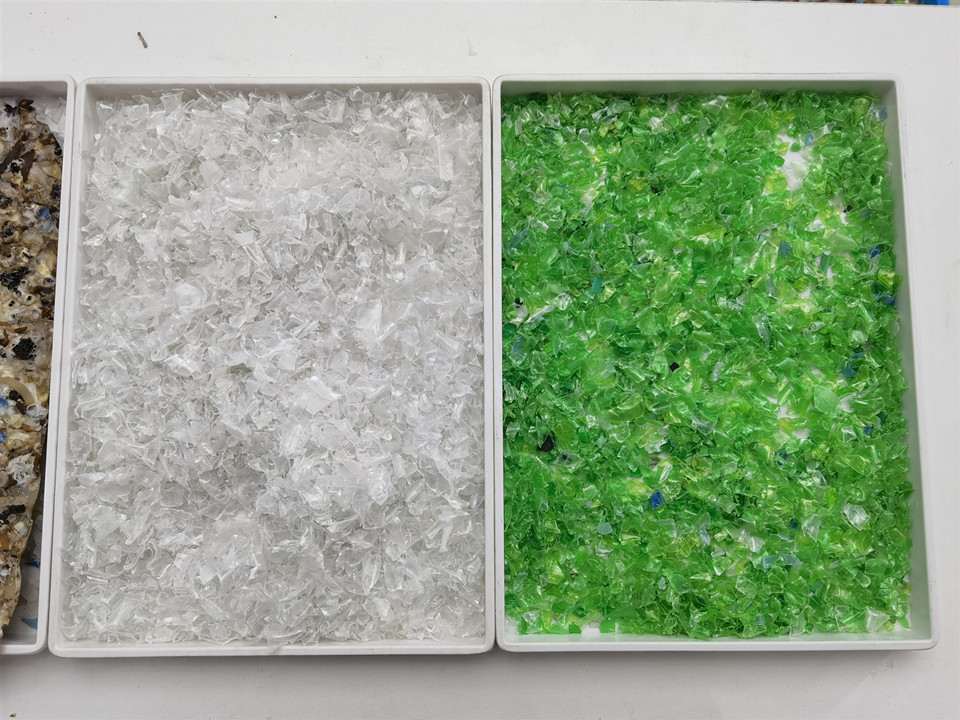

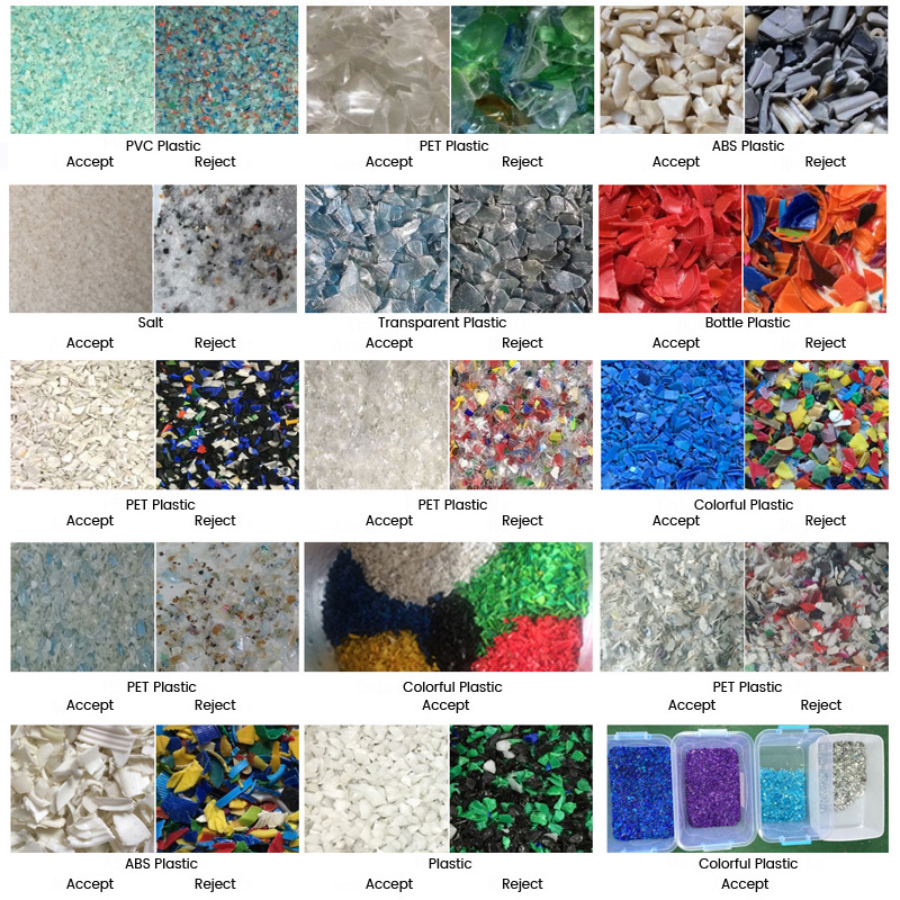

Optical plastic sorting is essential in any plastic processing operation as it helps you to achieve a purer quality of products for recycling plastic sorting.Raw material are fed at a carefully control flow rate to the conveyor belt,where a line of precision cameras scan each individualize pellet.Rejected materials are then removed from the product stream by compressed air jets.This machine features a two-stage(double belts) sorting system,increasing the purity.

In our daily life, plastic products can be found everywhere. Due to the short service life of plastics, the replacement of old and new is fast. As we all know, plastics are extracted from oil, which is a non-renewable resource, and the more it is used, the less it is, so it is necessary to recycle waste plastics. At present, China's waste plastic recycling method is classified - washed - dried - crushed - to form particles. Later, it is sold to plastic factories as recycled materials, which realizes the recycling of plastic resources. Some of them use traditional treatment for landfill, incineration, etc. Landfill not only needs to occupy a large number of sites, if the anti-seepage measures are improper, the produced leachate will enter the surrounding surface water or infiltrate into the soil, causing long-term serious pollution to the environment around the landfill and the health of residents. Waste plastic incineration will produce toxic gases to pollute the air, and the toxic and harmful substances in the bottom ash after incineration still need to be landfilled or further harmlessly treated. Therefore, the sorting and recycling of waste plastics is becoming more and more important .

With the continuous update of modern technology, the screening of waste plastics no longer needs to be carried out manually, and the plastic color sorter has gradually become the savior of the plastic sorting and recycling industry.With its unique advantages, plastic color sorter has become an important part of the waste plastic sorting and recycling line. The purity of the treated waste plastic is higher.The cost of recovery is higher and the profit margin is larger.

* Black specks

* Spots

* Foreign material

* Discolorations

* Dye drops

Optical Plastic Sorting Machine for plastic flake

Advanced sensor-based sorting technology for optimized results

Plastic flake sorting: Consistently exceptional quality

Your challenge:Achieving high purity highest purity pet flakes intended for the production of new transparent bottles must offer purity higher than 99.99% (<100 ppm). Anything less could prevent the use in bottle-to-bottle applications.

Our answer: Achieve high purity – continuously automatic sort flake analyzes and sorts flakes precisely by color and material, including metal. By combining a field-proven mechanical setup with advanced sensor technology to ensure precise sorting for even the smallest grain size.

The solution: Seamless and flexible

Plastic flakes are screened into grain size fractions of 2 and >2 - 12 mm.

The RC flake detects color (transparency) and material (eg: Pvc, colored pet, pe, pp, ferrous and non-ferrous metals… Etc.) of the fine particles all at the same time, ejecting impurities and undesirable colors.

The result: Pet with extremely high and constant purity (<100 ppm for a global contamination) with very low material loss (<1%), meeting the requirements of bottle-to-bottle & sheet recycling.

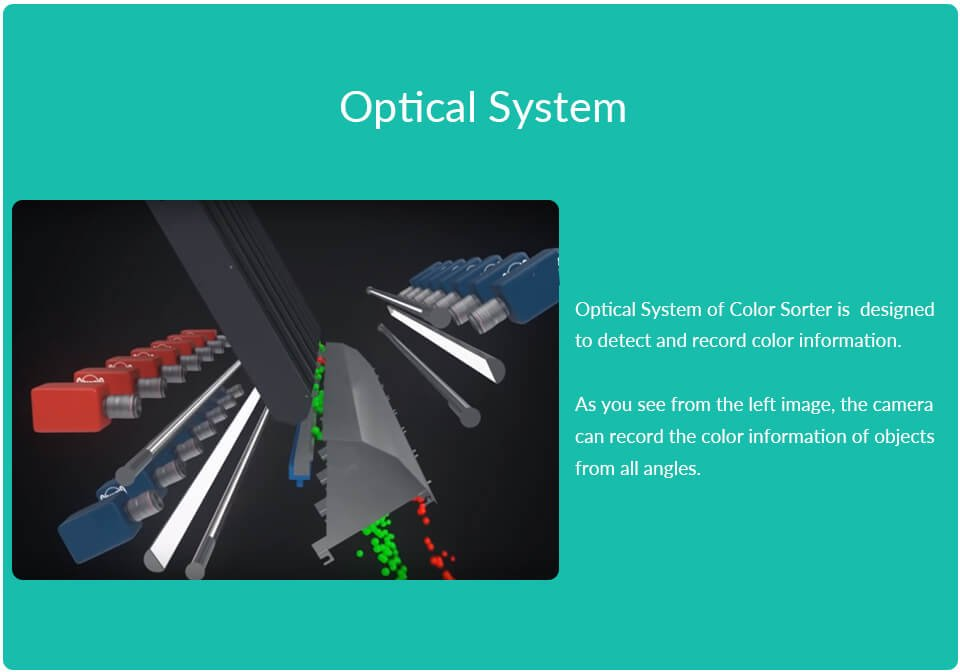

1,Advanced image acquisition system

Use the high resolution CCD camera with high quality industrial lens to achieve clear and accurate image acquisition .The camera could capture the micro defects of material instantly.

2,High reliability

Use high signal-to-noise ratio sensor and anti-interference circuit system,which could highly improve stability and reliability.

3,Intelligent image processing algorithm

Color sorting algorithms of gray level,color difference and HSV are perfectly combined with shape sorting algorithms of size,circular degree,texture etc,and successfully solved a series of high difficulty color sorting problems,and dramatically enhance the sorting accuracy.

4,Unique chutes processing technology

The special anodizing and hardening technology can greatly improve the channel smoothness and ware resistance to guarantee high production.

5,High quality solenoid valve(ejector)

Equipped with high quality solenoid valve.The valve has longer lifespan ,high frequency ,and low air consumption.The working frequency is 1000 times per second,which guarantees the accurate and perfect

ejecting.

For the different sizes and characteristics of material particle, Bird Machinery optical sorters use the solenoid valve of different sizes.

6,High efficiency and reliable light source

Advanced LED lighting technology with advantages of super high intensity,long lifetime and perfect performance.

7,Simple operation, easy to learn and use

Simple optical system design, precise automatic correction system, combined with the well-designed human-machine interface to simplify the complexity of machine commissioning and use.Our machine is intelligent so it can learn by itself.Our machine can take a photo of the material and then the machine could set the parameters by itself.

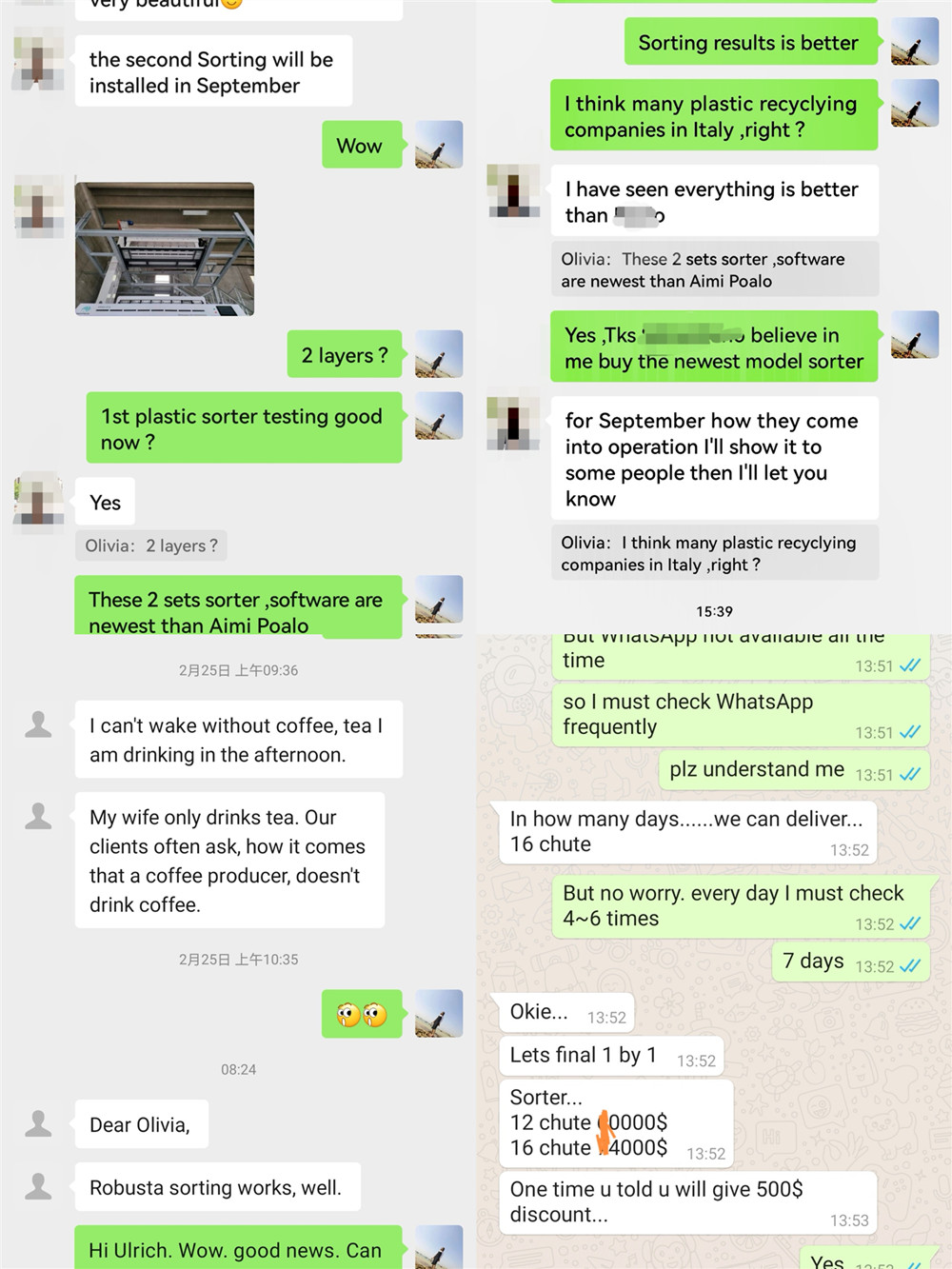

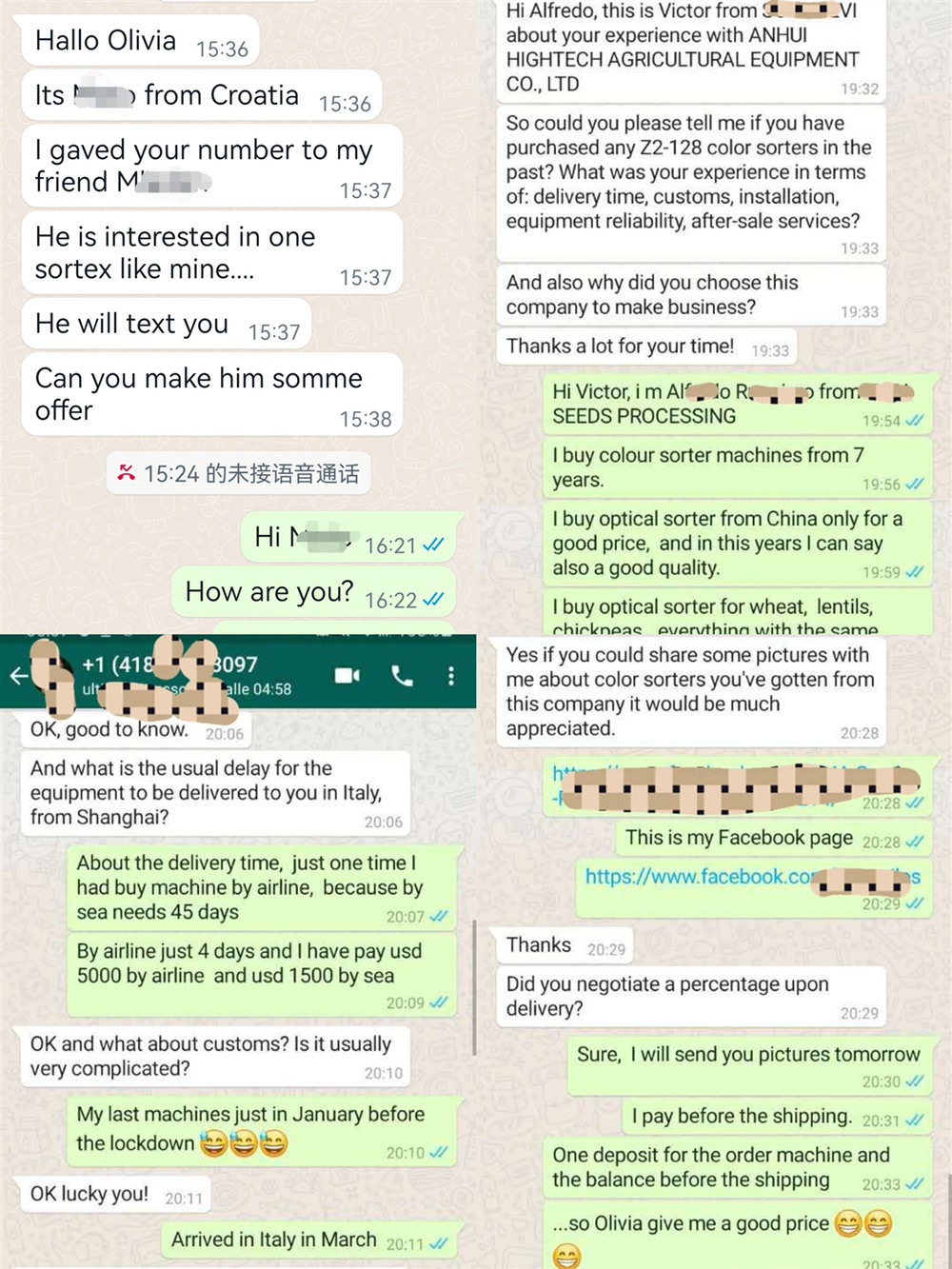

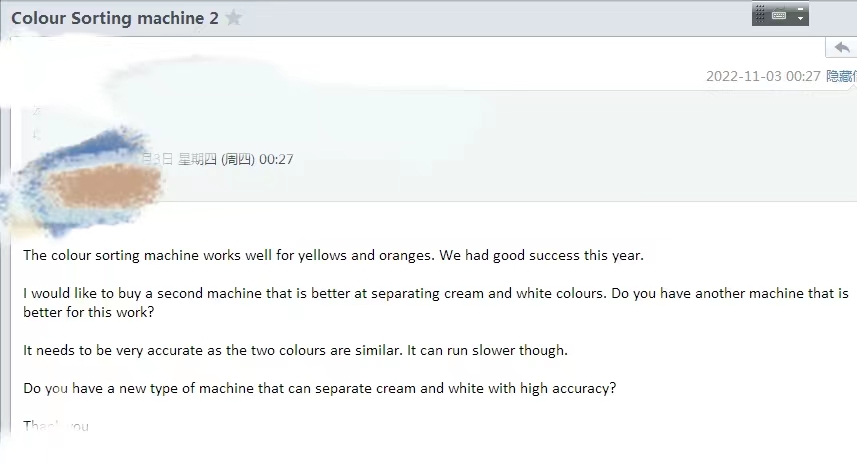

Customer feedback is the driving force behind our progress:

Plywood Case is Suitable for Sea/Road/Air Transport:

1. How to use the machine?

We will supply the Installation instructions and videos for guiding you how to set color sorter.

2. How long about the guarantee period?

Two years. And we supply lifelong software upgrade services for our customers.

3. Can you supply the air compressor, air tank and air filters?

Yes, we can provide above equipments, our standard offer includes color sorter machine with air compressor & air tank & air dryer & air filters.

4. Is oversea service available?

Yes, we will send engineer go abroad when you need it.

5.How to calculate Installation personnel cost?

On condition that customer requires to install, our company would like to send 1 engineer to guide for installation, then customer should to pay the cost, including transaction of engineer’s visa, transportation(air) for go abroad. and accommodation , local transportation and security when the engineer arrived.

6. If you have agent in our country?

We have agent in UK,New Zealand,Italy,Crotia,India, Guatemala,Finland,Malaysia,Bangladesh,Pakistan,Nigeria,Ukraine,Nicaragua etc. and we can provide after-sales service in your Country.

We have many installation cases and working videos.Please contact us freely if you need.

X

X