Intelligent plastic color sorting machine was called plastic color sorter ,plastic flakes sorting machine or plastic sorting machine.It adopts high-pixel image sensor, equipped with high-speed automatic identifying and analyzing system, it can sort needed materials from rejected one, so that material quality is greatly promoted.

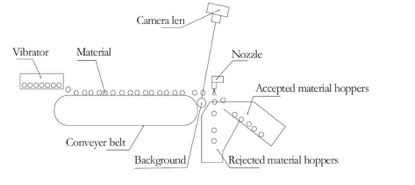

1. The selected materials like the plastic enter the machine from the hopper at the top.With the vibration of the vibrator device,the selected materials are conveyed along the channels,enter the observation area of the sorting room, and passe between the sensor and the background plate.

2. Under the affect of the light,the system generates an output signal to drive the solenoid valve to blow out the different-colored particles to the waste hopper with the intensity of the light and the color change.And the good materials continue to fall into the finished hopper .

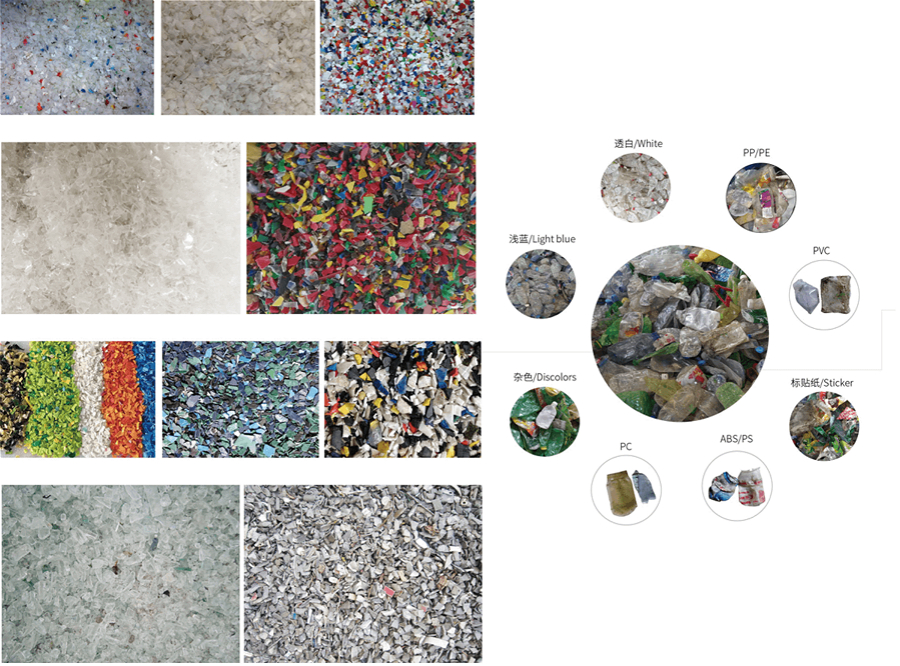

Recycling plastic sorting Application:

Such as Waste Plastics, Plastic pellet, HDPE/LDPE bottle falkes,Plastic pieces, Plastic granule, Plastic bottle cap flake, PET bottle scrap, ABS plastic

flake, PP plastic scrap,PS plastic scrp,PE , Recycled plastic, others.

Plastic color sorter can separate mixed plastic by different colors ,you can get 99.9% pure single color plastic at last .

| Model |

MPCS3 |

MPCS5 |

MPCS7 |

|

Capacity(t/h) |

1-1.5 |

1.5-2.5 |

2.5-4 |

|

Number of Execution Units |

180 |

300 |

420 |

|

Size of Sorting(mm) |

2*2-30*30 |

2*2-30*30 |

2*2-30*30 |

|

Power(kw) |

1.8 |

2.4 |

3.5 |

|

Dimensions(L*W*H)(mm) |

1455*1597*2142 |

2075*1597*2142 |

2625*1597*2142 |

|

Weight(kg) |

940 |

1330 |

1650 |

Plastic materials goes through hopper into the machine, shaken by the vibration device, the material slides through distributing box, an then pass through detector and background board.

Under the light resource, the light sensor receives compound light from the material, and the system sends out signals, driving the movement of the ejection valve, and remove off color material to the eject chamber. Accepted material freely falls down to the finished-product chamber, so that the material is precisely sorted.

* Separate various colors;

* Efficiently sort needed material from rejected one;

* Adopts latest software, highly precise sorting, with low product loss;

* Strengthened spout and air jet design for high per-cent contaminated material, durable and dependent;

* Adopts high-resolution image sensor, equipped with high-speed automatic identifying and analysing system;

* New type touch-screen operation platform, big colorful screen and user-friendly operation interface, can easily change sorting precision to the best quality;

* Except for some traditional functions like double-face sorting and second-time sorting, it also has more intelligent functions, which simplify operation and handle.

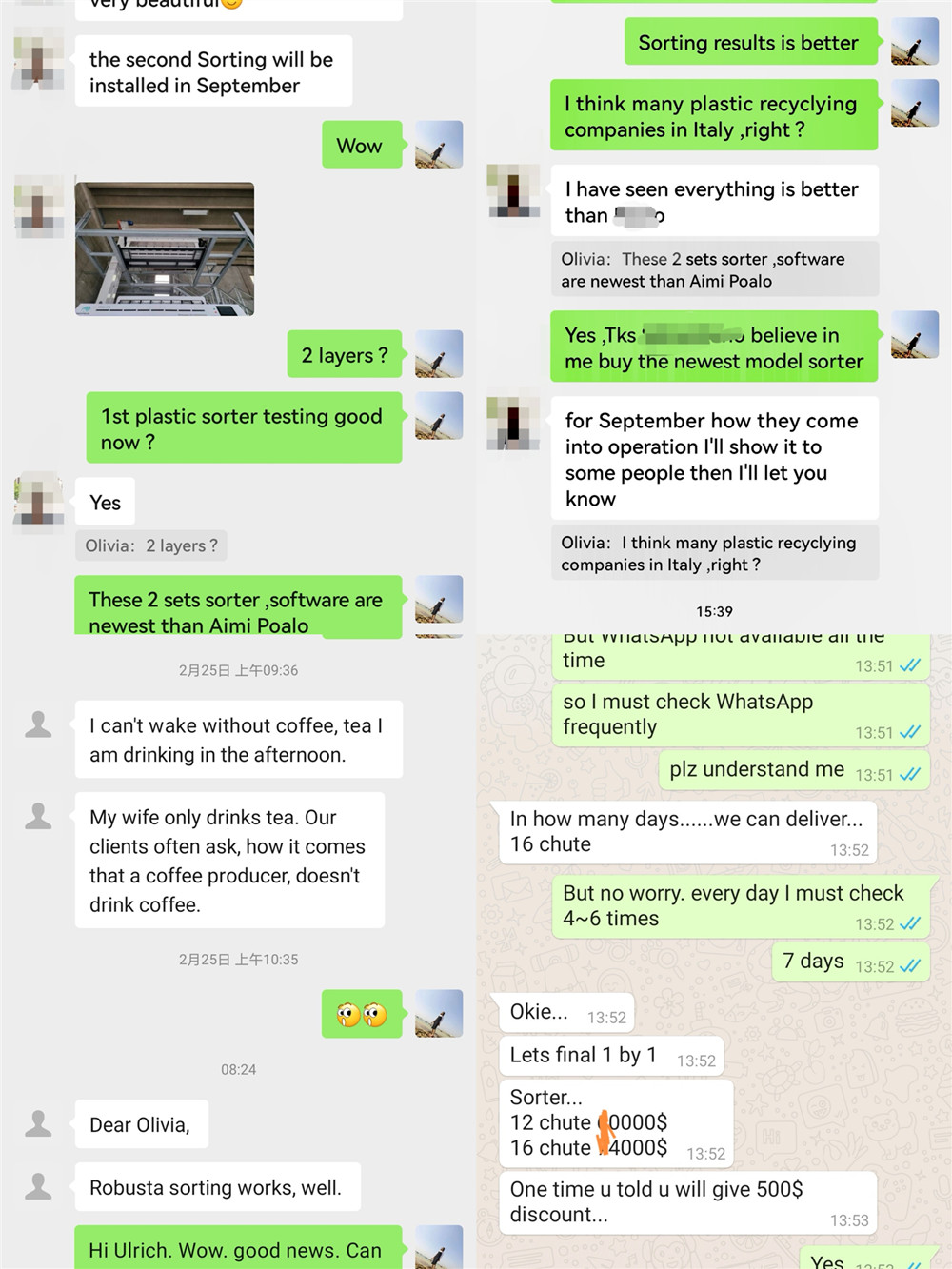

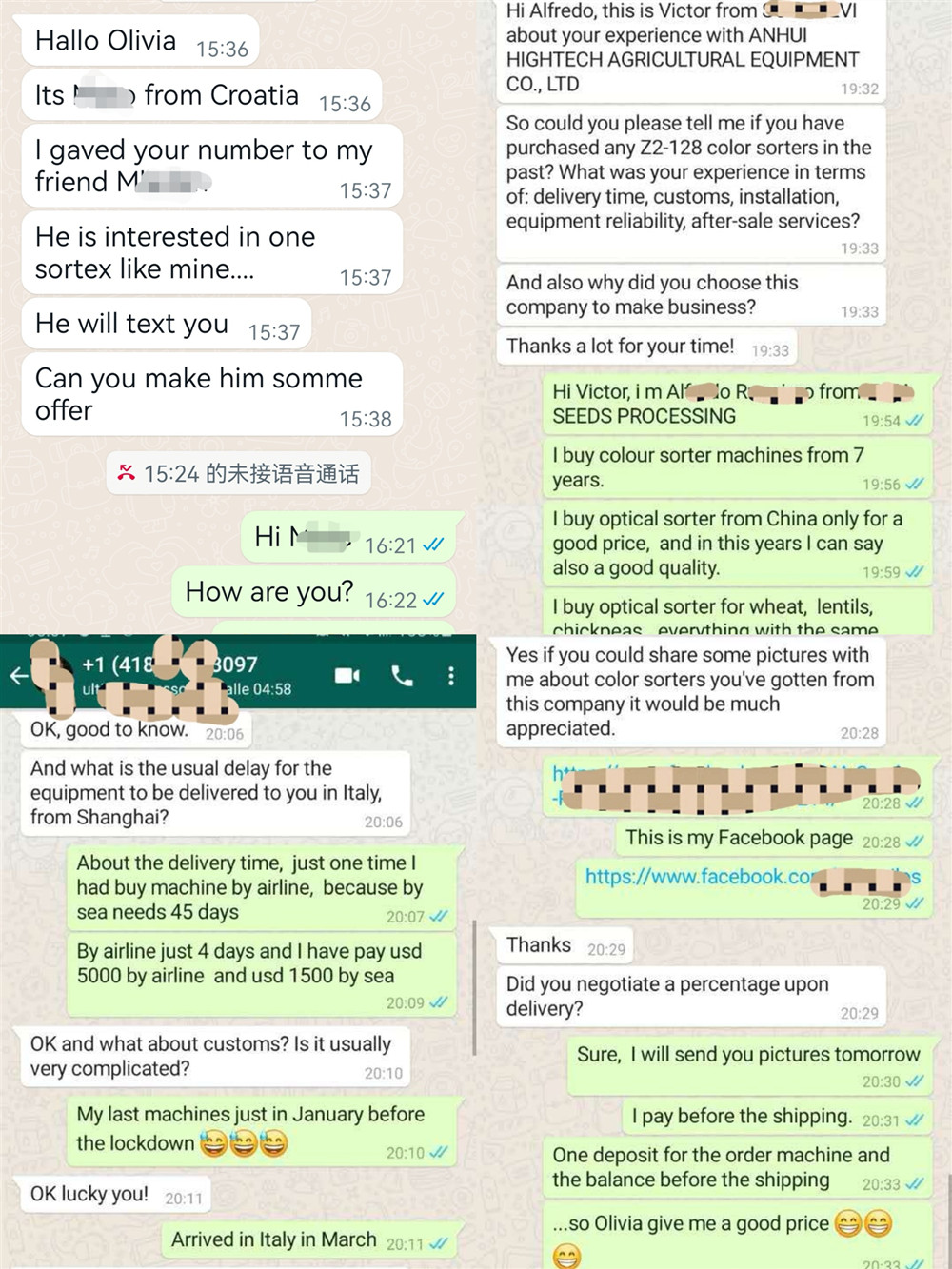

Customer feedback is the driving force behind our progress:

Plywood Case is Suitable for Sea/Road/Air Transport:

1. How to use the machine?

We will supply the Installation instructions and videos for guiding you how to set color sorter.

2. How long about the guarantee period?

Two years. And we supply lifelong software upgrade services for our customers.

3. Can you supply the air compressor, air tank and air filters?

Yes, we can provide above equipments, our standard offer includes color sorter machine with air compressor & air tank & air dryer & air filters.

4. Is oversea service available?

Yes, we will send engineer go abroad when you need it.

5.How to calculate Installation personnel cost?

On condition that customer requires to install, our company would like to send 1 engineer to guide for installation, then customer should to pay the cost, including transaction of engineer’s visa, transportation(air) for go abroad. and accommodation , local transportation and security when the engineer arrived.

6. If you have agent in our country?

We have agent in UK,New Zealand,Italy,Crotia,India, Guatemala,Finland,Malaysia,Bangladesh,Pakistan,Nigeria,Ukraine,Nicaragua etc. and we can provide after-sales service in your Country.

X

X