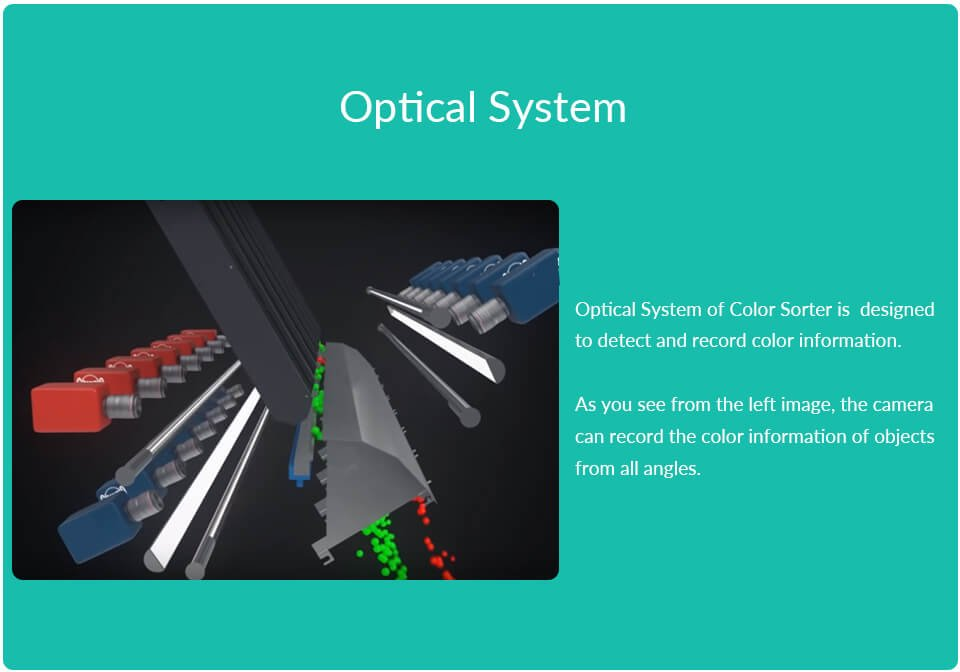

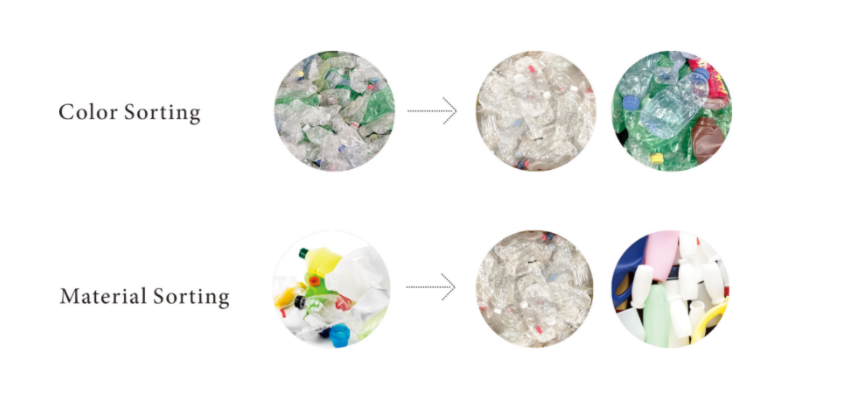

Plastic bottle color sorter machine ,suitable for sorting washed, unwashed, labeled, unlabeled round bottles, mixed plastic bottles in bale form, loose plastic bottles and other bottles of various shapes.The Pro series plastic bottle sorting machine integrates hyperspectral recognition technology and AI deep learning technology to accurately identify the material, color, and characteristics of plastic bottles. It effortlessly captures subtle spectral differences on the surface of plastic bottles, accurately distinguishing different materials and colors.

Sorting samples as followed:

|

Model |

Capacity (T/H) |

Voltage |

Power (kw) |

Dimensions (L*W*H)(mm) |

Weight (kg) |

|

G-LPI2 |

1.5-2.0 |

380V/50Hz |

10 |

7360*1870*2660 |

4000 |

|

G-LPI4 |

3.0-4.0 |

380V/50Hz |

14 |

7360*1870*2660 |

5500 |

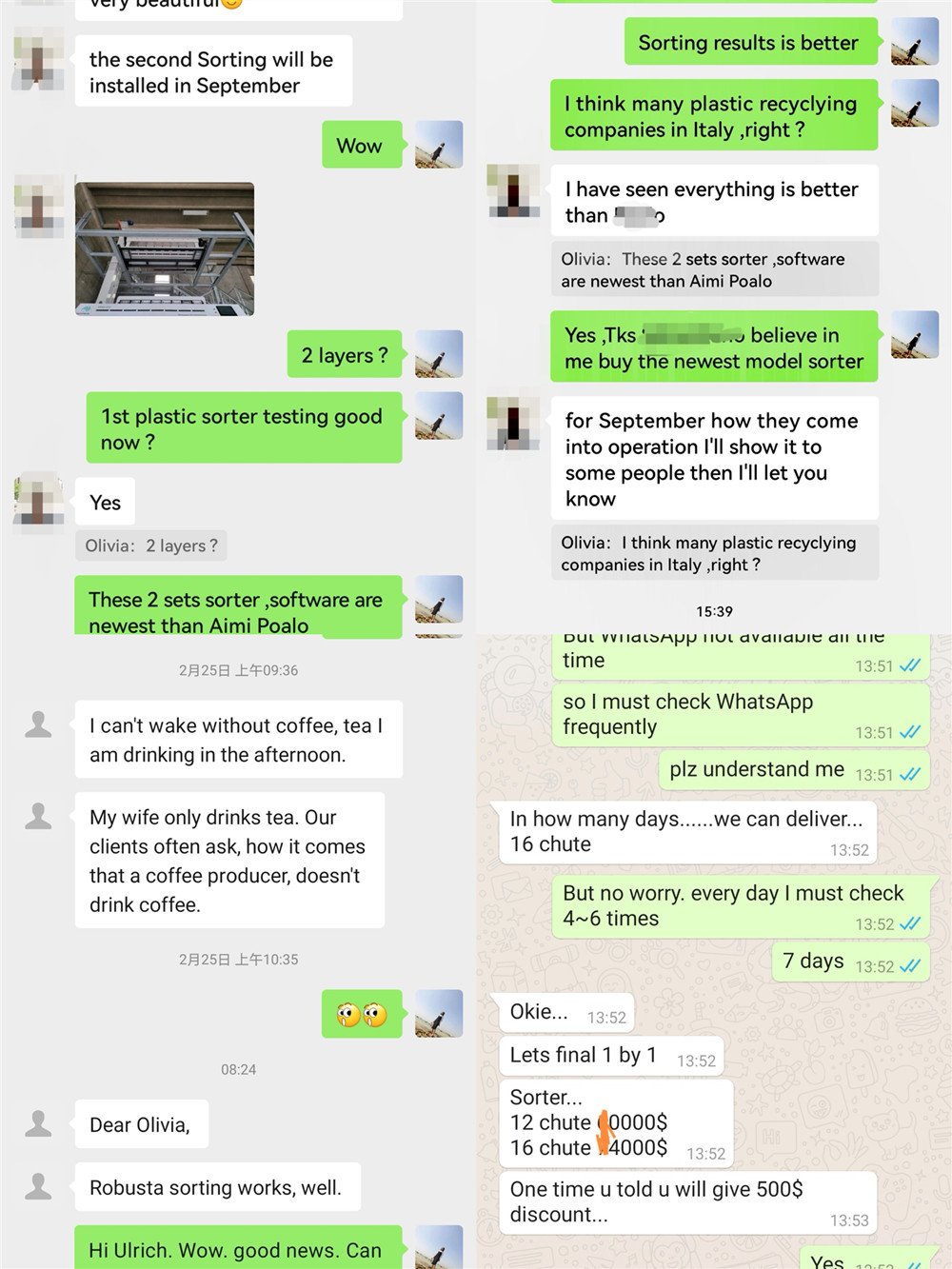

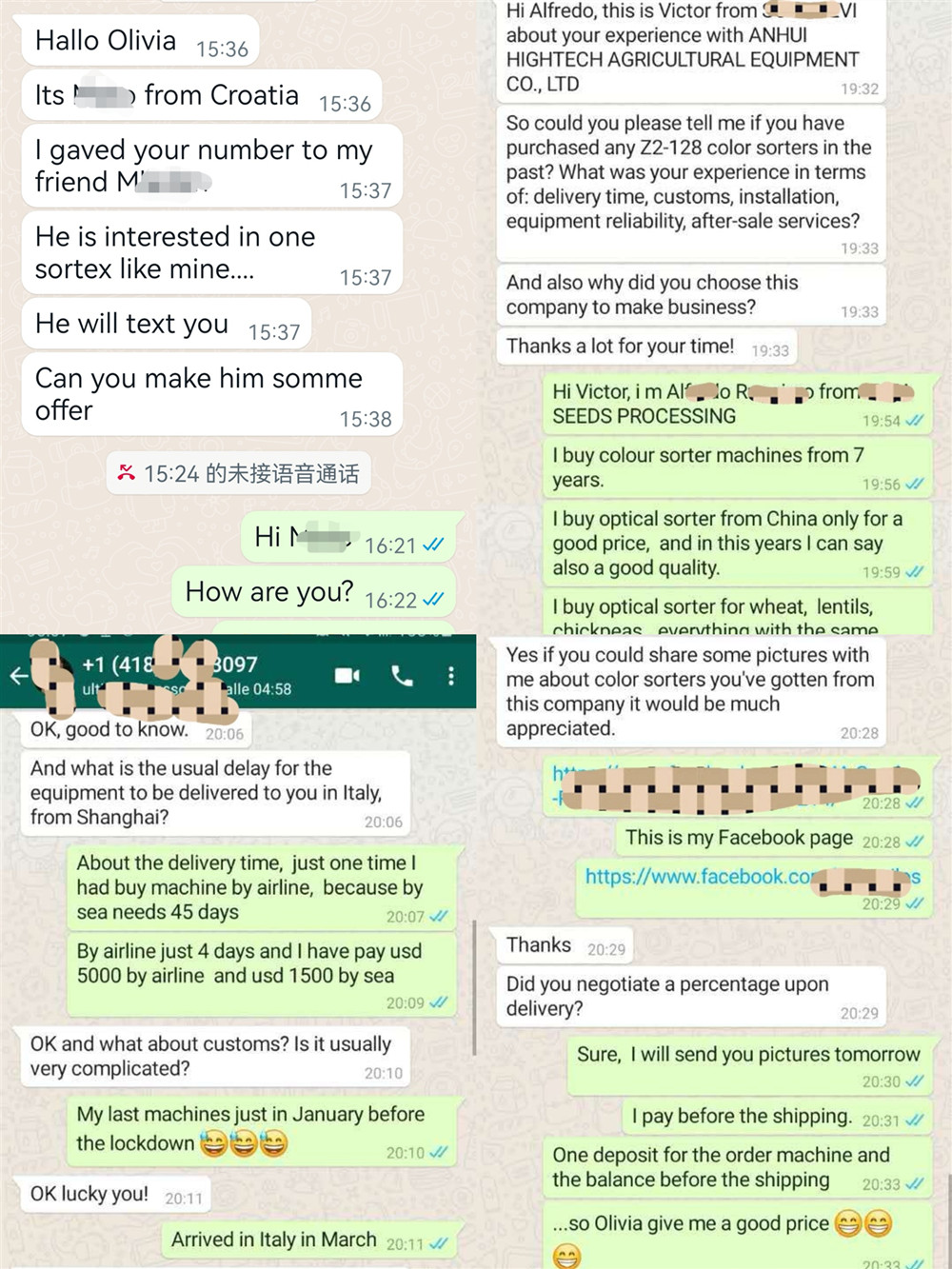

Customer feedback is the driving force behind our progress:

Customer feedback is the driving force behind our progress:

Plywood Case is Suitable for Sea/Road/Air Transport:

1. How to use the machine?

We will supply the Installation instructions and videos for guiding you how to set color sorter.

2. How long about the guarantee period?

Two years. And we supply lifelong software upgrade services for our customers.

3. Can you supply the air compressor, air tank and air filters?

Yes, we can provide above equipments, our standard offer includes color sorter machine with air compressor & air tank & air dryer & air filters.

4. Is oversea service available?

Yes, we will send engineer go abroad when you need it.

5.How to calculate Installation personnel cost?

On condition that customer requires to install, our company would like to send 1 engineer to guide for installation, then customer should to pay the cost, including transaction of engineer’s visa, transportation(air) for go abroad. and accommodation , local transportation and security when the engineer arrived.

6. If you have agent in our country?

We have agent in UK,New Zealand,Italy,Crotia,India, Guatemala,Finland,Malaysia,Bangladesh,Pakistan,Nigeria,Ukraine,Nicaragua etc. and we can provide after-sales service in your Country.

We have many installation cases and working videos.Please contact us freely if you need.

X

X