As concerns over environmental sustainability continue to grow, the recycling of plastic materials is becoming increasingly important. One of the most commonly recycled plastics is polyethylene terephthalate (PET), which is commonly used in the production of water bottles, soft drink bottles, and other consumer products.

As concerns over environmental sustainability continue to grow, the recycling of plastic materials is becoming increasingly important. One of the most commonly recycled plastics is polyethylene terephthalate (PET), which is commonly used in the production of water bottles, soft drink bottles, and other consumer products. However, recycling PET bottles can be a challenging process, as it requires the separation of the bottle flakes by color and quality. Fortunately, polymer sorter for recycling PET bottle flakes are revolutionizing the recycling industry and making it easier and more efficient than ever before. In this article, we'll discuss how these machines work and the advantages they offer for plastic recycling.

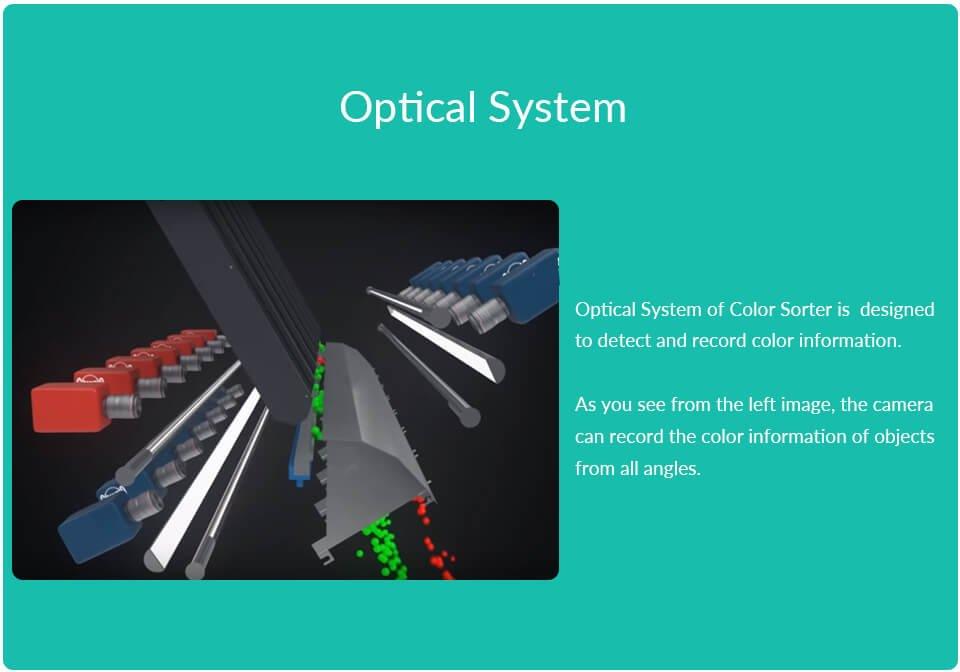

How Plastic Sorting Machines Work: Plastic sorting machines for PET bottle flakes use advanced imaging technology to sort the flakes based on their color and quality. The machines use high-speed cameras and sophisticated software algorithms to capture images of each PET bottle flake as it passes through the sorting process. The software analyzes the images and identifies any defects or impurities, such as non-PET materials, other colored plastics or contaminants like labels and caps.

Once identified, the machine separates the defective flakes from the good ones using a series of air jets, mechanical arms or other technologies. This results in a batch of high-quality, uniformly colored PET bottle flakes that are ready for further processing.

Advantages:

1.Increased Efficiency: Sorting PET bottle flakes by hand can be a time-consuming and labor-intensive process. Plastic sorting machines can sort PET bottle flakes at a much faster rate, resulting in a more efficient sorting process and faster turnaround times.

2.Improved Quality: PET bottle flake sorting machines can identify and remove defective or impure flakes, resulting in a higher quality batch of PET bottle flakes that are more desirable to buyers.

3.Cost Savings: By automating the sorting process, plastic sorting machines can reduce labor costs and improve the overall profitability of a recycling operation.

4.Customizable Options: PET bottle flake sorting machines can be customized to meet the specific needs of a recycling operation, ensuring that they get the most out of their investment.

5.How PET Bottle Flake Sorting Machines Help Plastic Recycling: Investing in a PET bottle flake sorting machine can help plastic recycling operations increase their profits in several ways. First, by improving the quality of their PET bottle flakes, recycling operations can command a higher price from buyers. Second, PET bottle flake sorting machines can reduce the amount of waste and rejected flakes, resulting in a higher yield and increased profits. Finally, PET bottle flake sorting machines can increase the efficiency of the sorting process, resulting in faster turnaround times and increased production capacity.

Conclusion: If you're in the plastic recycling industry and looking to improve your efficiency and profitability, investing in a PET bottle flake sorting machine is a smart choice. With its advanced imaging technology and efficient sorting process, a PET bottle flake sorting machine can improve the quality of your PET bottle flakes, reduce waste, and increase your production capacity, resulting in higher profits for your business. Contact us today to learn more about how a PET bottle flake sorting machine can benefit your plastic recycling operation.

| Model |

MPCS3 |

MPCS5 |

MPCS7 |

|

Capacity(t/h) |

1-1.5 |

1.5-2.5 |

2.5-4 |

|

Number of Execution Units |

180 |

300 |

420 |

|

Size of Sorting(mm) |

2*2-30*30 |

2*2-30*30 |

2*2-30*30 |

|

Power(kw) |

1.8 |

2.4 |

3.5 |

|

Dimensions(L*W*H)(mm) |

1455*1597*2142 |

2075*1597*2142 |

2625*1597*2142 |

|

Weight(kg) |

940 |

1330 |

1650 |

Plastic materials goes through hopper into the machine, shaken by the vibration device, the material slides through distributing box, an then pass through detector and background board.

Under the light resource, the light sensor receives compound light from the material, and the system sends out signals, driving the movement of the ejection valve, and remove off color material to the eject chamber. Accepted material freely falls down to the finished-product chamber, so that the material is precisely sorted.

* Separate various colors;

* Efficiently sort needed material from rejected one;

* Adopts latest software, highly precise sorting, with low product loss;

* Strengthened spout and air jet design for high per-cent contaminated material, durable and dependent;

* Adopts high-resolution image sensor, equipped with high-speed automatic identifying and analysing system;

* New type touch-screen operation platform, big colorful screen and user-friendly operation interface, can easily change sorting precision to the best quality;

* Except for some traditional functions like double-face sorting and second-time sorting, it also has more intelligent functions, which simplify operation and handle.

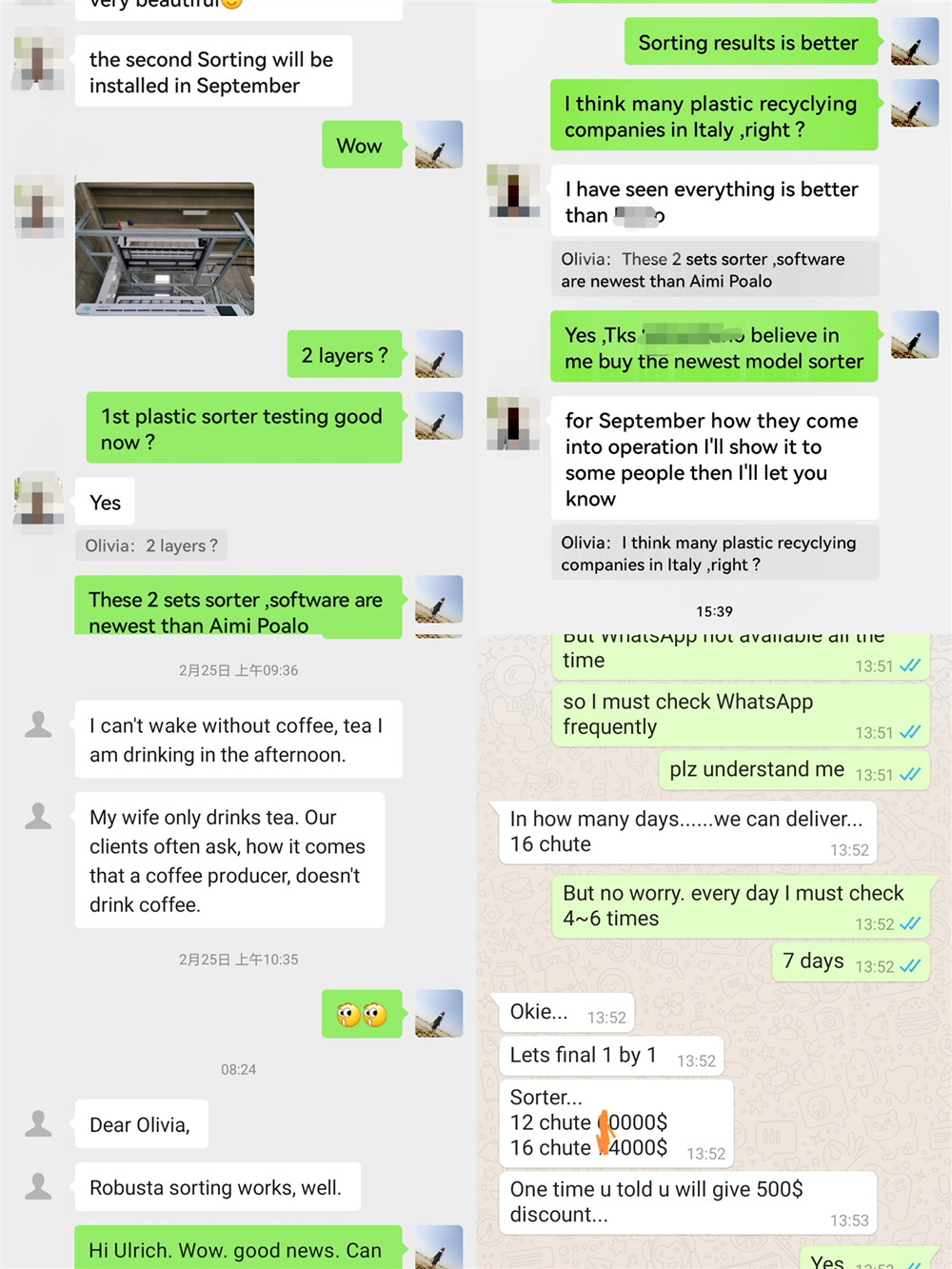

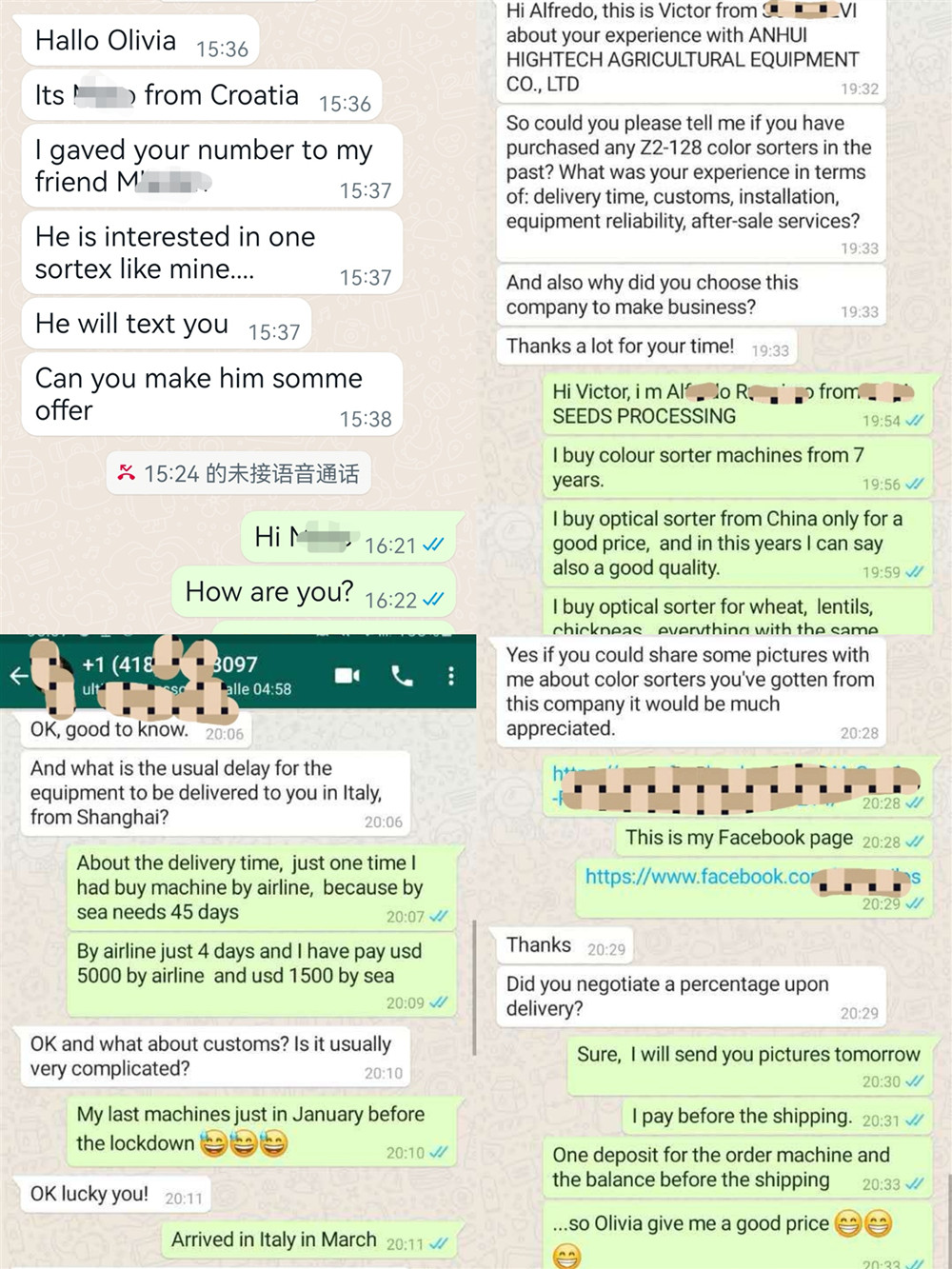

Customer feedback is the driving force behind our progress:

Plywood Case is Suitable for Sea/Road/Air Transport:

1. How to use the machine?

We will supply the Installation instructions and videos for guiding you how to set color sorter.

2. How long about the guarantee period?

Two years. And we supply lifelong software upgrade services for our customers.

3. Can you supply the air compressor, air tank and air filters?

Yes, we can provide above equipments, our standard offer includes color sorter machine with air compressor & air tank & air dryer & air filters.

4. Is oversea service available?

Yes, we will send engineer go abroad when you need it.

5.How to calculate Installation personnel cost?

On condition that customer requires to install, our company would like to send 1 engineer to guide for installation, then customer should to pay the cost, including transaction of engineer’s visa, transportation(air) for go abroad. and accommodation , local transportation and security when the engineer arrived.

6. If you have agent in our country?

We have agent in UK,New Zealand,Italy,Crotia,India, Guatemala,Finland,Malaysia,Bangladesh,Pakistan,Nigeria,Ukraine,Nicaragua etc. and we can provide after-sales service in your Country.

X

X