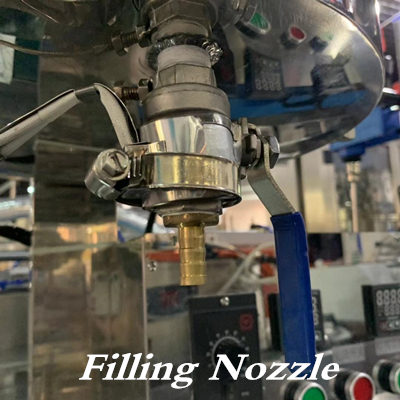

Lipstick heating filling Machine it mainly consists of heating and mixing tank, and filling part. The filling nozzle is at the bottom of tank. The whole equipment adopts paddle stirring and pneumatic filling valve. Filling head is heated in nozzle jacket. Pedal control and automatic filling transform by switch.

Working process: Take lipstick into the tank, be heated to a definite temperature, stir as well then filling into mold. stirring speed is infinitely adjustable.

Features:

♦ Designing the tank by dual layers, product is heated by oil in jacket.

♦ Praticability working, and low cost to invest for equipment.

♦ It adopts france brand compressor in 5P, with perfect chilling efficiency.

|

No |

Item |

Description |

|

1 |

Hopper volume |

30L for each hopper; double layers and oil removal heating |

|

2 |

Filling Capacity |

1~14ml/piece |

|

3 |

operator |

One person |

|

4 |

Filling speed |

20-30pcs/min |

Product details:

FAQ:

Q: Do you sell one piece of machine? What is your lead time?

A: Yes we do. Small machine within 10 days, Custom machine within 35 days, Custom project within 60 days.

Q: What is the shipping method?

A: It could be shipped by sea, by air or by express(EMS, UPS, DHL, TNT, FEDEX and ect). Please confirm with us before placing orders.

Q: What about your Service and Warranty?

A: Regarding service: After customers purchase our machine, you can enjoy life-long service. If you have any questions about the machine, please contact us.

Warranty period: within 6 months after the goods are received, during the period, if the machine is not damaged by man, we can replace the parts free of charge, except for freight.

X

X