♦3 times overload capacity, bottom cogging torque, response speed

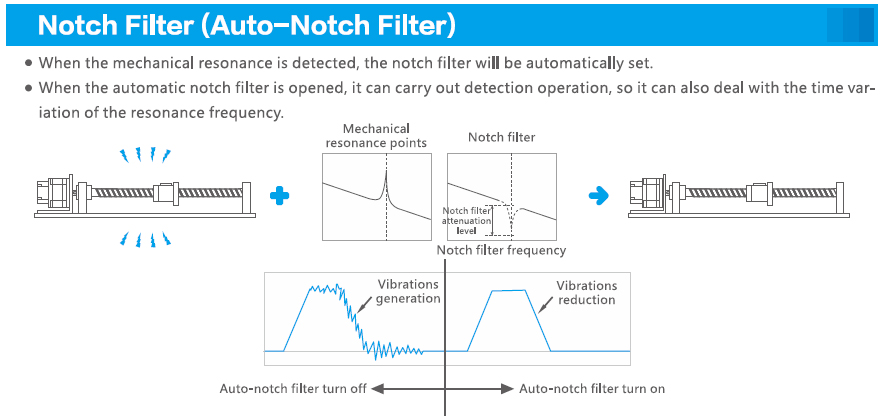

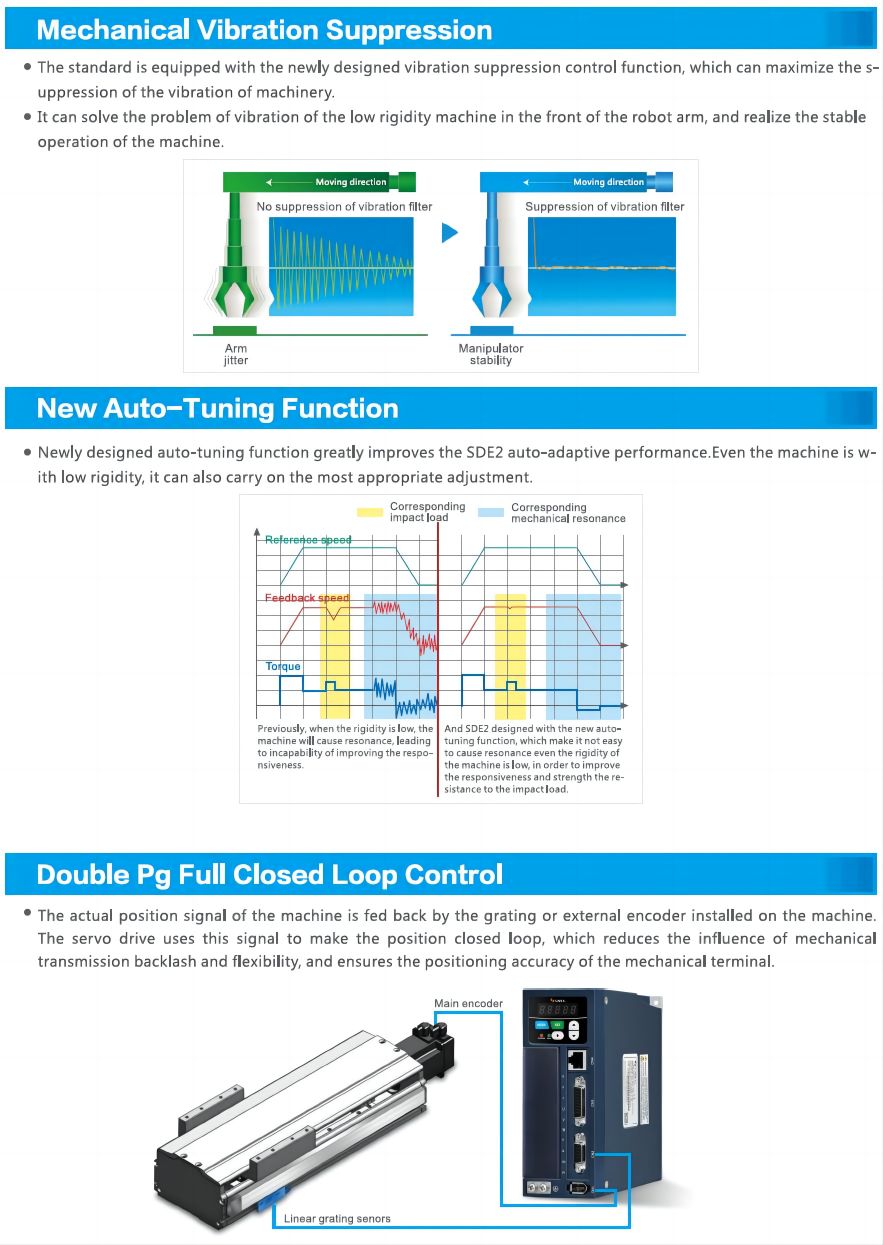

♦Identification of Load Inertia,real-time Automatic Gain Adjustment,Automatic/Manual Notch filter

♦Friction Torque Compensation,built-in Regeneration resistance

♦Input/Output Signal Assigned,electronic Cam Control,gain switch

♦Torque limit change,Interrupt position control,gantrysynchronization control

♦Fully closed-loop control,high flexibilityinternallocation programming mode

SCH-SDE2 cost-effective servo driver

The SDE2 series is a cost-effective servo system (motor & drive), which can be widely used in a large industry, suchas laser marking machine joint robot, linear mechanical hands, wood machinery, glass machinery, injection moldingmachinery, welding and cuting equipment, ceramic equipment, textile equipment, testing equipment, cable equipmentlithium battery equipment, electronic manufacturing equipment, miling machines, grinding machines, CNC lathes, foodproduction lines, packaging production line, engraving and miling machine, engraving machine, high light machinearound line machine, warp knitting machine, labeling machine, veneer machines etc

Technical Specification

| ltem | Specifications | |

| Input Power | Single/three phase 220V,three phase 380V | |

| Voltage variation range (-15%~+10%)50/60Hz | ||

| Cooling Method | Fan cooling | |

| Main Circuit Control Mode | IGBT PWM sine wave mode | |

| Feedback | 2500 line(standard)/17 bit | |

| Control Mode | ①Position control ②Speed control ③Torque control ④Position/speed mode switch ⑤Position/torque mode switch ⑥Speed/torque mode switch ⑦Positioning operation mode |

|

| Position Control |

Max input pulse frequency |

Line Drive input:Max 500kHz Open Collector Input:Max 200kHz |

| Command pulse input mode |

①Command pulse/command signal ②Forward rotating pulse and reverse rotating pulse ③A/B phase orthogonal pulse |

|

| Command control mode |

①External command pulse input control ②Internal position data control | |

| Electronic gear | Electronic Gear N/M times (N:1~4194304)/M:1~4194304) | |

| Torque limitation | Parameter control (Forward rotating and reverse rotating can be set respectively)/ External analog torque control |

|

| Speed Control |

Analog command input |

VREF DCO~±10V |

| Speed variation rate |

±1r/min or below (load range 0~100%) | |

| Speed range | 1:5000 | |

| Acceleration and deceleration time setting |

Acceleration time and deceleration time can be set respectively,and have two groups, and can accelerate and decelerate with S curve |

|

| Speed control mode |

External analog input/Internal speed setting | |

| Torque Limitation | Parameter control (Forward rotating and reverse rotating can be set respectively)/ External analog torque control |

|

| Torque Control |

Analog command input |

TREF DCO~±10V |

| Torque Limitation | Parameter control/External analog speed limitation | |

| Digital Input/ Outpu |

Input | EI1~EI66 lines input,the function can be set freely according to the parameter |

| Output | Encoder pulse outputs by frequency division,A/B phase output by line drive and Z phase open collector (Total 3 lines) |

|

| EOUT1~EOUT33 lines output,the function can be set freely according to the parameter |

||

| Monitor | Feedback speed,reference speed,reference torque,motor current,feedback of curre- nt location,Location Difference,reference pulse frequency,Feedback Pulse Accumul- ation,Reference Pulse Accumulation,VREF input voltage,TREF input voltage,input terminal signal,output terminal signal etc |

|

| Protection(Alarm display) | Overcurrent (oc1,oc2),Over speeding (oS),Overvoltage(Hv),Memory Error (dE),Enc- oder Error(Ec),Overload (oL1,oL2),Main circuit under voltage (Lu),EI Repeat (ctE), Deviation overflow (oF),Servo motor drive overheat (AH)etc |

|

| Applica- tion Environ- ment |

Site location | Indoors (Avoid direct sunlight),No corrosive gas (Avoid smoke,methane) |

| Ambient Temperature |

0~50℃(When the ambient temperature is higher than the required one please introduce air circulation) |

|

| Storage Temperature | -20℃~75℃ | |

| Relative humidity | RH 90%lower (No condensation) | |

| Altitude | Lower than 1000m | |

| Atmospheric pressure | 86~106kPa | |

| Vibration | ≤0.5G | |

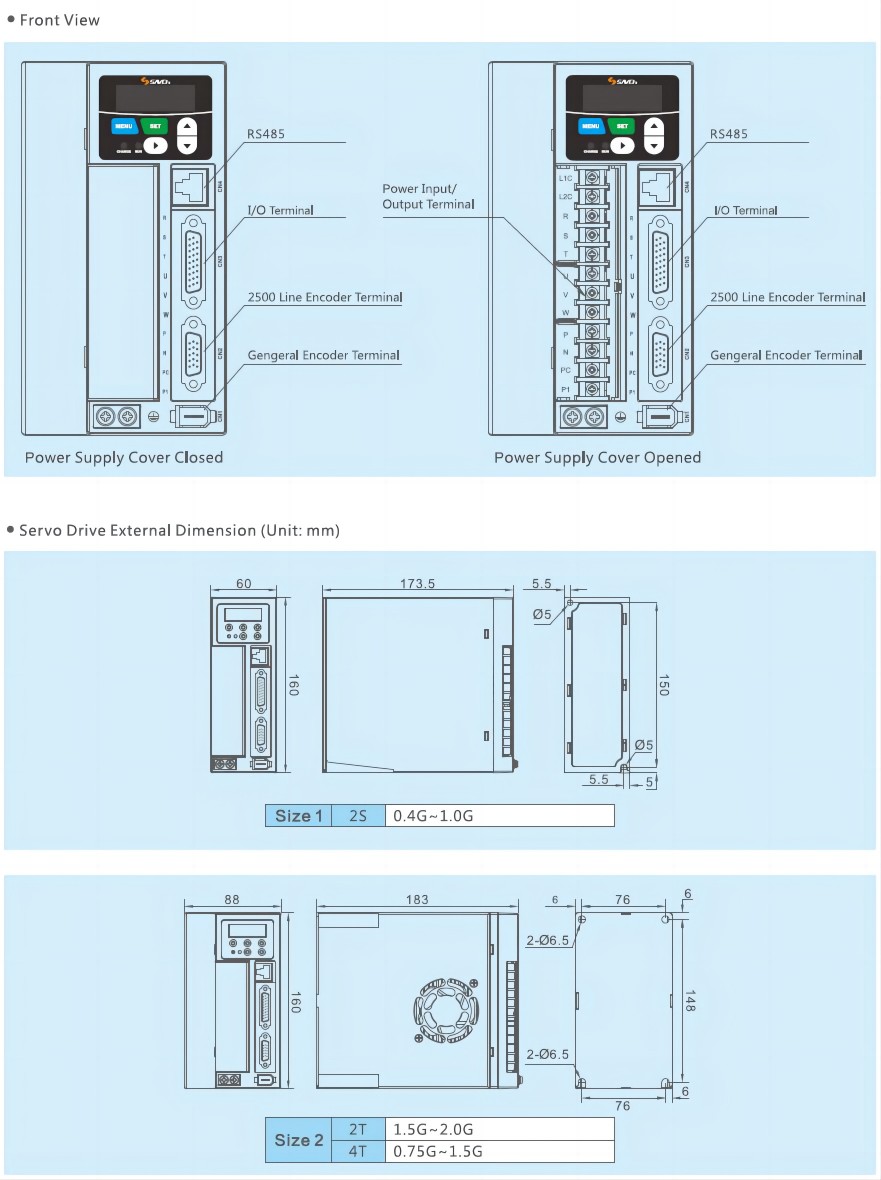

Product Characteristics

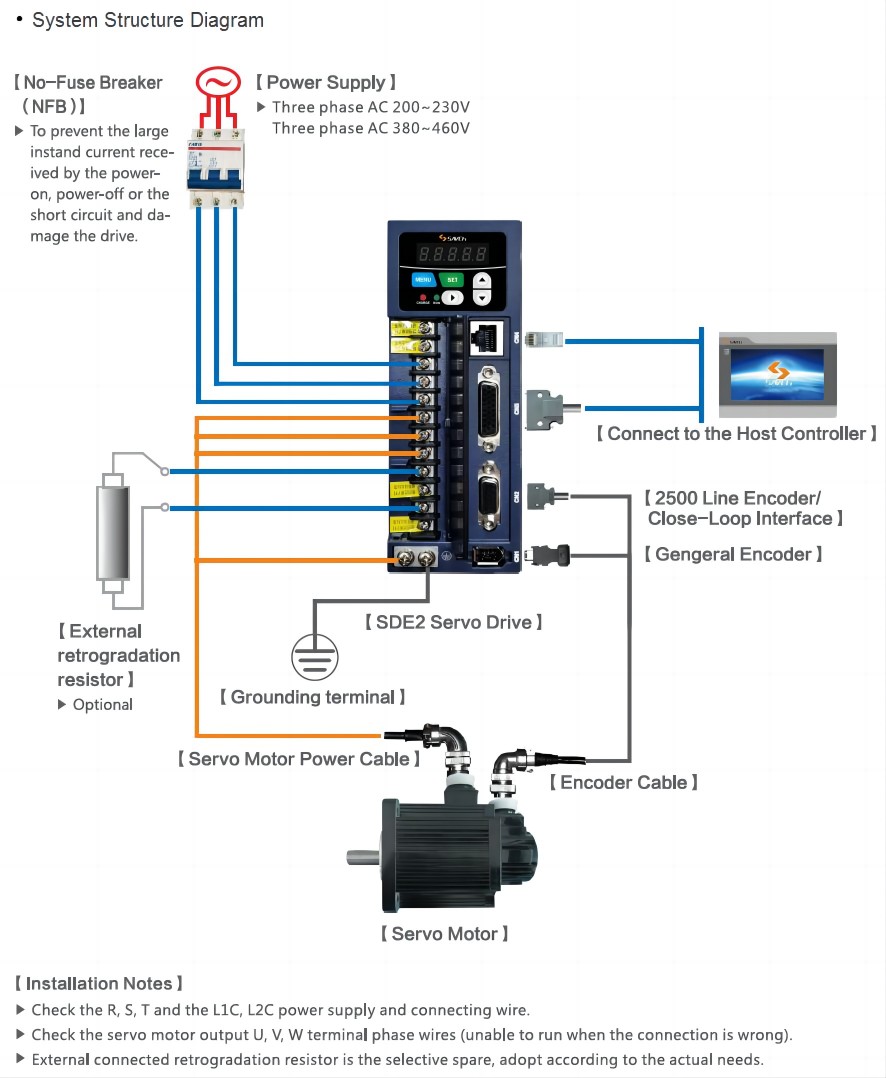

Product Wiring diagram

Optional Accessories

FAQ

Can you produce according to the samples or drawings?

Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

What is the lead time?

For standard models, lead time is about 3~5 days after order confirmed and payment received.

For OEM orders, the delivery is about 2~3 weeks after data confirmed and payment received.

How to solve the quality problems after sales?

Take photos or videos of the problems and send to us.

We will make a satisfied solution for you within 24 hours after we confirm the problems.

X

X