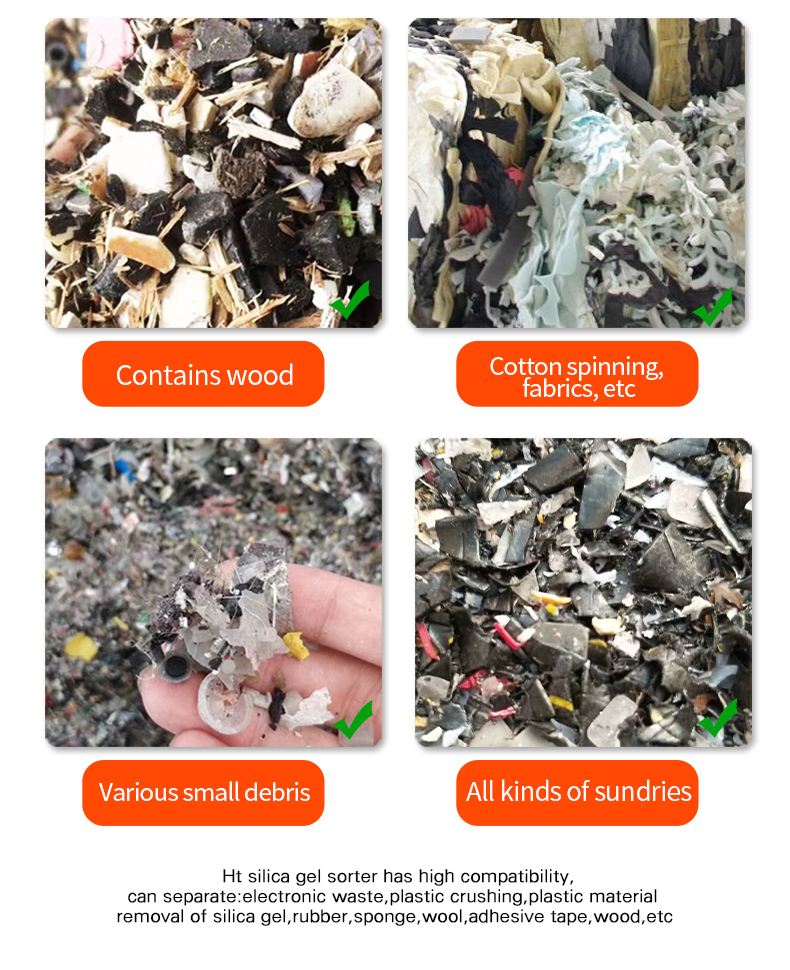

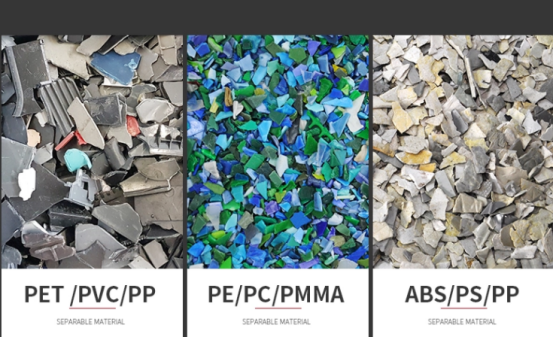

Electrostatic separators of particles:Application to sorting mixed plastic scraps for the recycling purpose.Like PET/PVC, ABS/PMMA, PS/ABS, PVC/rubber, PVC/PE,HDPE/PP, PP/PS etc.

Plastics recycling business ideas helps you to earn money as well as save the environment. Recycling plastic is the process of converting waste material into new material. It is like making the best of waste.

How to sort PET flakes from the mixed PP plastics or PE flakes ? Our plastic electrostatic separators with advanced technology can achieving a purified plastics-fraction using a dry process at low separation costs.

Material mixes of PET/PVC, ABS/PMMA, PS/ABS, PVC/rubber, PVC/PE,HDPE/PP, PP/PS, and many others are efficiently separated.

You can therefore use mixed plastics waste as a valuable raw material for new high grade products. Your mixed materials can be separated into pure sorted fractions with a minimum of effort by using the tribo-electric behaviour of the different plastics. You can therefore use mixed plastics waste as a valuable raw material for new high grade products.

---High purity.

PS≥99%,PP≥99%;ABS≥99%,PE≥99%;

It will be reach to 100% pure if resorting .

---High efficiency, large output.

Input capacity:1-1.5T/H;2-3T/H;4-5T/H;

---Safe low current: 2 mA-4mA;

---Save a space, cover an small area.

The whole electrostatic sorting machine is section construction,which covers about 50 square meters,also can adjust according to the Installed base.

---NO waste for the environment.

The electrostatic separator sorting machine works in dry condiction, making granules with electrostatic for easily separator.

There is no Waste residue, waste water, waste gas occured. it will not pollute the environment again.

Operating principle:

Our electrostatic plastics separators use differences in tribo-electrical behaviour to separate( PET /PVC),(ABS/PS/PP),(PP/PE),(PC/PMMA).

The input material is introduced into a so-called tribo-electric charging unit via a vibrating conveyor. The plastics are selectively and differently charged here according to the specific plastic. Like PET and PVC , PET particles take on here a positive charge, while the PVC becomes negatively charged. This effect is brought about by transfer of electrons from one article to another.

After having been successfully charged, the plastic mixture reaches a high voltage field, where the PVC particles become separated from the PET due to their different charge.

Colour contamination can be removed entirely automatically with our colour sorting machine installed further downline .

Technology Parameters:

|

Name |

Model |

Capacity |

Size |

Power |

|

Plastic Electrostatic Separator |

R500 |

0.5-0.8T/h |

3.5x2.5x5.75m |

9KW |

|

|

R1500 |

1.0-1.5T/h |

4.0x3.0x5.75m |

11KW |

|

|

R3000 |

2.0-3.0T/h |

4.5x3.5x5.75m |

12.5KW |

|

|

R5000 |

4.0-5.0T/h |

4.5x3.5x5.75m |

30KW |

X

X