Plastic electrostatic separation machine, also known as electrostatic plastic separator, is a kind of equipment for mixing waste plastic material separation, often used in the field of plastic recycling.

Plastic electrostatic separation can separate different materials of plastics, often used in plastic waste, household appliances shell crusher, electric vehicle crusher, toy crusher and other plastic waste ABS/PS/submerged PP/flame retardant ABS/flame retardant PS, PET, PVC, PA, PE, PA separation .

Plastic electrostatic sorting machine is used in the field of waste plastic recycling, and after the plastic of mixed materials is separated, the single material of plastic will be improved in terms of sales value and recycling quality.

Are you still bothered by these issues? 1. For mixed plastics, manual sorting costs are high. 2. There are many kinds of mixed plastics, and the selling price is not high. 3. Do not know what equipment can be used to sort mixed plastics, to ensure the purity of plastics, such as ABS plastics in PP, PS materials, etc.

---High purity.

ABS≥98%,PS≥98%,PE≥98%,PP≥98%;

It will be close to 100% in second separating.

---High efficiency, large output.

Input capacity:1-1.5T/H;2-3T/H;4-5T/H;

---Safe low current: 2 mA-4mA;

---Save a space, cover an small area.

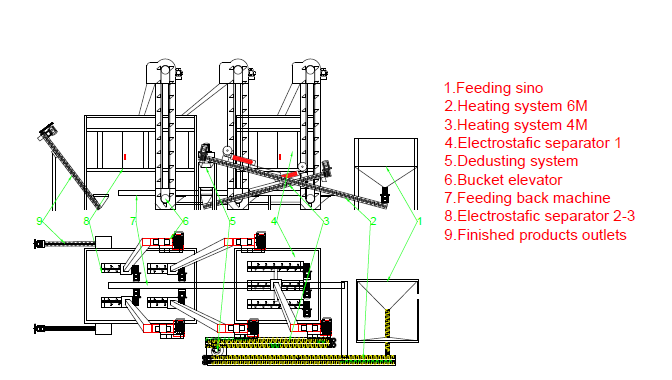

The whole electrostatic sorting machine is section construction,which covers about 50 square meters,also can adjust according to the Installed base.

---NO waste for the environment.

The electrostatic separator sorting machine works in dry condiction, making granules with electrostatic for easily separator.

There is no Waste residue, waste water, waste gas occured. it will not pollute the environment again.

---Engineers available to service machine overseas.

We have a professional and experienced engineers team, they can read your mechanical design drawings and help you deal with mechanical failure.If you have some revised the machine, we will give you our professional suggestions and do it according to your requirements.

Requirements for your material:

In order to obtain an optimum separation result with our machine, the plastic mixtures to be separated must have the following characteristics:

We have many installation cases and working videos.Please contact us freely if you need.

X

X