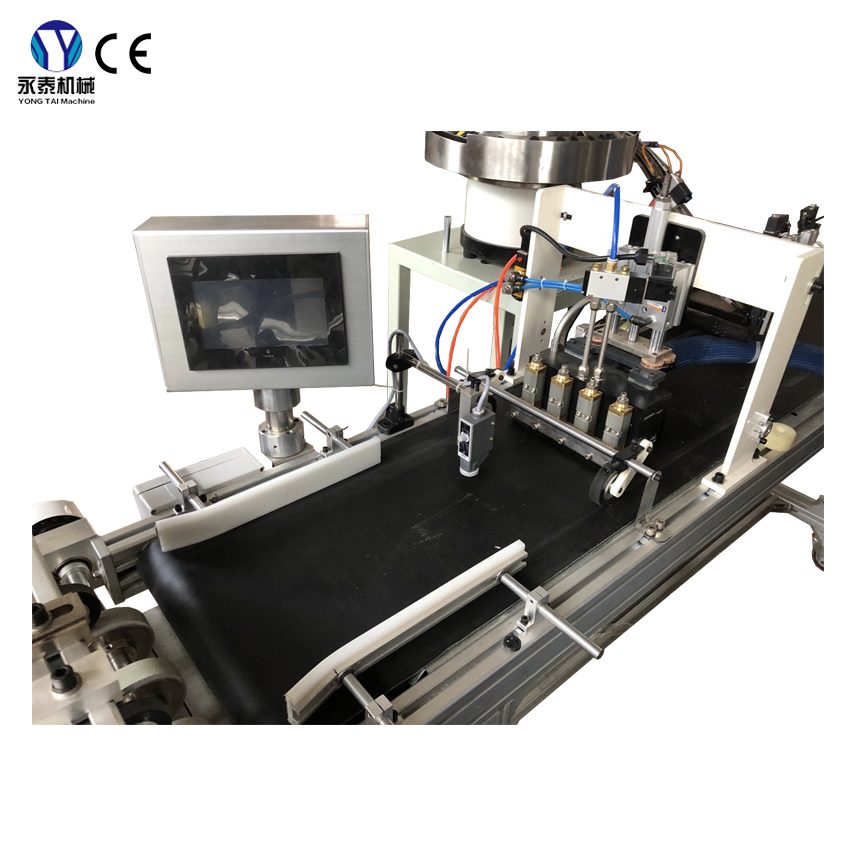

Hot melt coating machine to make sticky mouse and insect traps.

The machine YT-LS210 is including glue melt tank, hot melt hose, slot die,auto feeder, transmission part, pneumatic control part, electric part.

a) Glue melt tank

1. The glue pump speed is controlled by gear motor

2. Temperature of each layer is controlled by PID system independently

3. Max. temperature is 220℃

4. Melt glue speed: 45kg/hr

5. Heating power: app. 6 KW

6. Main Motor:0.4KW

b) Hot Hose

1. A 3m length hot melt hose provided.

2. 220V AC , 900 w power.

c) Slot die 210mm

1. Coating head: use 3 valves Independent control

2. Mounted on Pneumatic piston for up – down moment

3. Coating width adjustment with shimps insert

4. Levelling in transfers direction to conveyor is provided.

d) Auto Feeder

1. An automatic system for feeding one board at a time is provided.

2. An adjustable edge guiding scale provided for change in size.

3. A PVC belt conveyer belt provided for carrying the board.

e) Transmission part

1. Main motor: 2 KW 1 set

2. Negative pressure fan power:1.1KW 1 set

3. Main machine driven by use of belt, chain and gear to transmit.

f) Pneumatic control part

1. Cylinder on slot die, feeding and stopping with head: ¢50mm for each

2. Suitable solenoid valves, flow control and connectors.

g) Electric part

1. Main machine VFD: 2 KW; 1 piece

2. Glue tank VFD: 1 KW; 1 piece

3. Temperature controller: digital PID

4. Heaters: 8KW

5. Touch screen: 10” 1set

6. PLC: 1 set

|

Specification: |

|

|

Board size Min. and Max. |

10" max. width and 4" min. width |

|

Coating size |

210mm (Max.) X 100mm (Min.) |

|

Max. Machine Speed |

30 Pcs/min @ 28gms per pad |

|

Main Motor |

2 KW (VFD adjusted speed) |

|

Max Gluing Width |

210 mm |

|

Glue Tank Capacity |

30 kg |

|

Machine Size |

1000x700x1400mm |

|

Power Requirement |

10 Kw, 380V, 50HZ, 3 Phase |

X

X