Competitive Advantage:

1. 18 Months Guarantee for quality.

2.OEM manufacturer, print client’s LOGO on the valve body.

3.Offer Operation Manual & Install Introduction for safety use.

4.Offer manufacturer’s reasonable price to win the market for both.

5.Accept any the third party inspection.

6.As a factory, every production process can be controlled during manufacture.

7.Offer inspection & testing reports for raw materials, production process, wall thickness, face to face dimension, pressure test, welding test, painting test, etc.

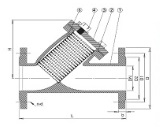

Y strainer cast iron ductile iron

Y type filter is an indispensable filter device for pipeline system of conveying medium. Y type filter is usually installed at the inlet end of pressure reducing valve, pressure relief valve, water level fixing valve or other equipment to remove impurities in the medium to protect the normal use of valves and equipment. Y filter has the characteristics of advanced structure, small resistance and convenient discharge. Y filter suitable medium can be water, oil, gas. The general water network is 18~30 mesh, the ventilation network is 10~100 mesh, and the oil network is 100~480 mesh. The basket filter is mainly composed of pipe, supervisor, filter blue, flange, flange cover and fastener. When the liquid enters the filter blue through the supervisor, the solid impurity particles are blocked in the filter blue, while the clean fluid passes through the filter blue and is discharged from the filter outlet.

Basic parameters:

1. medium temperature :300(℃);

2. working pressure differential :2 KG;

3. material: stainless steel;

4. product alias: Y filter;

5. Scope of application: liquid filtration;

6. connection form: flange;

7. type: right angle;

8. flow direction: one-way;

9. applicable media: water;

10. Pressure environment: atmospheric pressure.

Description of tables:

Application

1

Face to face is according to ANSI 125/150

2

Flange drilled is according to ANISB16.1/B16.5

3

Class 125

Flat face flange

4

Class 150

Raised face flange

| Test | ||

|

Working pressure |

125PSI |

150PSI |

| Shell pressure | 350PSI | 400PSI |

| seat pressure | 200PSI | 250PSI |

| Main Parts and Materials | ||

|

Number |

Part Name |

Material |

|

1 |

Body | A126B/A536 65-45-12 |

|

2 |

Cver Gasket |

Graphite With Steel |

| EPMD/NBR | ||

| 3 | cover | A126B/A536 65-45-12 |

|

4 |

Plug | Zine Steel NPT |

|

5 |

Bolt&nut |

Galvanized Flat Head Bolt |

| Galvanized stud Bolt | ||

| Stainless Steel | ||

|

6 |

Screen |

SS Wire Screen |

| SS Perforated Mesh | ||

|

Main Dimensions |

||||||||

|

DN |

L |

D |

D1 |

b |

n-d |

H |

Plug |

W.T |

| 1 1/2" | 200 | 127 | 98.6 | 14.2 | 4-16 | 135 | 1/2" | 6.5 |

|

2" |

225.4 | 152 | 120.7 | 15.8 | 4-19 | 150 | 1/2" | 9.6 |

|

2 1/2" |

273 | 178 | 139.7 | 17.5 | 4-19 | 160 | 1/2" | 12.3 |

| 3" | 292 | 191 | 152.4 | 19 | 4-19 | 200 | 1/2" | 17 |

|

4" |

352.4 | 229 | 190.5 | 23.9 | 8-19 | 240 | 1/2" | 28.1 |

|

5" |

416 | 254 | 215.9 | 23.9 | 8-22 | 290 | 3/4" | 40 |

| 6" | 470 | 279 | 241.3 | 25.4 | 8-22 | 330 | 3/4" | 49 |

| 8" | 543 | 343 | 298.5 | 28.5 | 8-22 | 380 | 3/4" | 82.3 |

|

10" |

660.4 | 406 | 362 | 30.2 | 12-25 | 480 | 1" | 127.3 |

| 12" | 762 | 483 | 431.8 | 31.8 | 12-25 | 550 | 1" | 200 |

|

14" |

946.3 | 533 | 476.3 | 35 | 12-29 | 680 | 2" | 320 |

| 16" | 1079 | 597 | 539.8 | 36.6 | 16-29 | 780 | 2" | 420 |

Packing & Delivery :

Packing Details : all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details : Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

X

X