No matter wooden grain or marble stone aluminum coil, it is referred from the natural material to reach the texture effect of wood and stone. The pattern comes from the painting original color after a high temperature baking of 224-255℃.

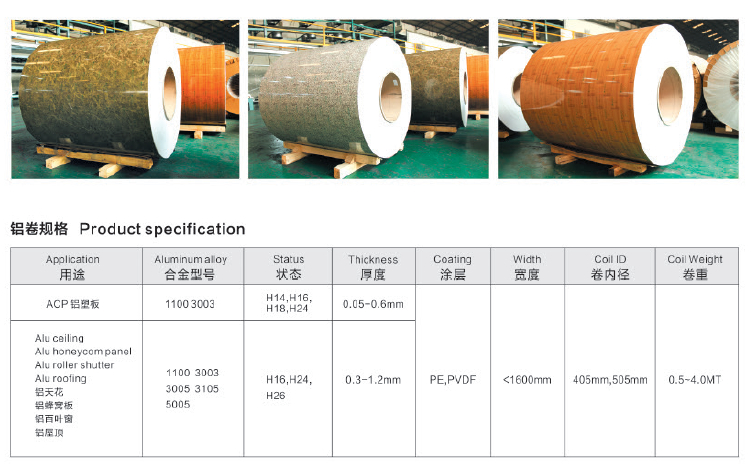

Wooden grain coated aluminum coils are widely applied to ACP,

aluminum ceiling, roofing, fireproof roller shutter, doors, wall panel , facade cladding, etc.

1. Specification for coated aluminum coils

01)Material: aluminum alloy A1100, A3003, A3005, A3105

02)Aluminum thickness:0.04-1.20mm

03)Max coil width: 1600mm(standard 1240mm)

04)Coil ID: 405mm,505mm, Coil OD: 1000-1400mm

05) Coil standard weight: 2500kgs/coil

06) Coating: PE or PVDF coating

07) Surface treatment: anti-scratch, glossy, matte

08) Color: wooden grain, marble stone, plain color,3D, HD, metallic, patterned, etc.

09) Dried and baked: oven baked at 450 degree F

10) Coating thickness: double coating-25 micron, single coating-18 micron

11) Coating hardness: (pencil hardness) 2H

12) Coating adhesive: no lower than first grade

13) Impact resistance: no cracking and peeling(50kg/cm, ASTMD-2794:1993)

14)Flexibility(T-bend):2T or by your option

15) MEK resistance: more than 100

16)Outer packing: wooden plate, covering with craft paper and film, Eye to Sky or wall to Sky packing.

2. Applications

Interior applications: ACP skin, door skin, wall cladding, ceilings, kitchen cabinet, balconies, shutters...

Exterior applications: roller shutters, gutters, wall cladding, facades, roofing, canopies, tunnels, column covers , renovations...

Advertisement and market applications: display platforms, signboards, fascia, shop fronts...

X

X