The 2nd generation WPC decking is produced by co-extrusion technique which is a new technique developed recently. Simply speaking, the process is to extrude two materials at the same time and give the boards a natural layered appearance and more protection. When you see our co-extruded decking, you are gonna love it.

The 2nd generation WPC decking is a new type of composite decking made of composite material as core and coated with super-performance polymer material. Compared to the traditional wpc products, Co-extrusion wpc provide multiple colors onto the surface to create wood-like texture. The outer layer are used surlyn plastic which is famous for being used to produce golf. The outer layer is four sided surrounding the core materials to give protection against oil, acid, insect, abrasion and UV. The thickness of the outer layer is crucial to the product quality, and we have strict procedures on quality control to make sure the thickness thicker than 0.5mm.

Decking Models

Different designs for different projects

Option Colors

Various of colors for choice, customized color is welcome

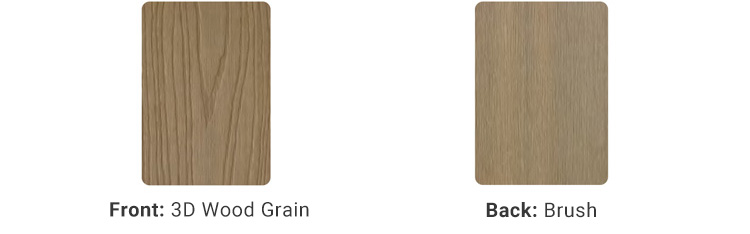

Surface Treatments

Enhance the resistance, better quality and surface

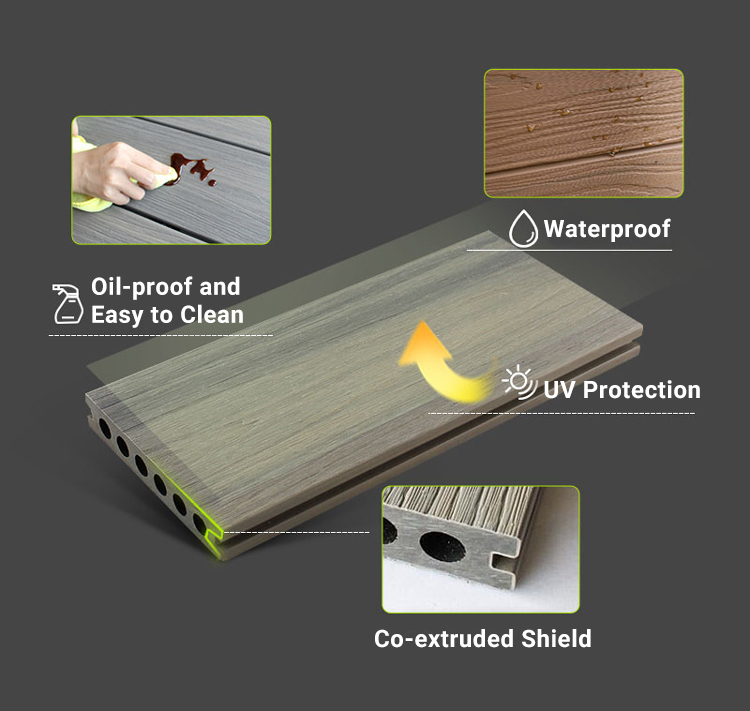

Features of Co-extruded WPC Decking

Why choose us: the advantages of our products

360 Degree Co-extrusion Layer Protection

Long life span and ease for maintenance

Patented Pedestal Joist System Design

Less labor cost and simple installation

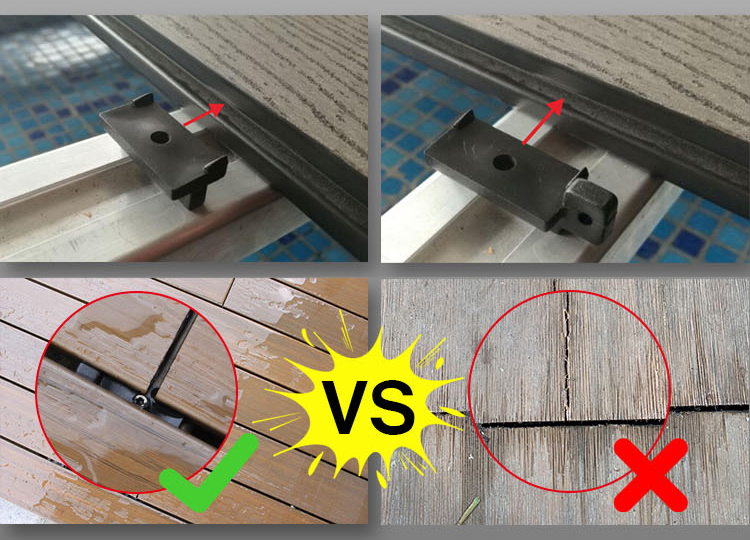

Patented Decking Clips Design

Efficiently Prevent Deformation or Cracking Due to Expansion

Case Study

Reference to the actual effect after the installation

X

X