SCH3000 series general purpose frequency inverter

SCH3000 series non-inductive vector frequency converter is a series of high-performance current vector type, low noise frequency converter, under the premise of improving stability to add simple PLC, practical PI regulation (with pressure water supply function), flexible input and output terminals, Parameter online modification, self-identification signal transmission fault, power outage and shutdown parameter storage, injection molding machine energy-saving control, swing frequency control,RS485 control, fieldbus control and a series of practical and effective operation, control functions; For the equipment manufacturing and end customers to provide a highly integrated series of solutions, to reduce the system procurement and operating costs, improve the reliability of the system to help.

| Item | Standard specification | |

| Input | Rated voltage/frequency: | Single-phase 220V, three-phase 200V, three-phase 380V; 50Hz/60Hz |

| Allowable variation: | Voltage: -20%~+20%Voltage imbalance rate: <3%Frequency: ±5% | |

| Output | Rated voltage: | 0~200V/220V/380V |

| Frequency range: | 0Hz~500Hz | |

| Frequency resolution: | 0.01Hz | |

| Overload capacity: | 150% rated current for 1 minute, 180% rated current for 3 seconds | |

| Main control functions | Modulation mode: | Optimized space voltage vector SVPWM modulation |

| Control mode: | Insensitive vector control (with optimal low frequency dead band compensation characteristics) | |

| Frequency accuracy: | Digital setting: maximum frequency X ± 0.01%;Analog setting: maximum frequency × ± 0.2% | |

| Frequency resolution: | Digital setting: 0.01Hz;Analog setting: maximum frequency × 0.1% | |

| Starting frequency: | 0.40Hz~20.00Hz | |

| Torque increase: | Automatic torque increase, manual torque increase 0.1%~30.0% | |

| V/F curve: | Five modes: constant torque V/F curve, one user-defined multi-segment V/F curve mode and three torque reduction characteristic curve modes (2.0 power, 1.7 power and 1.2 power) | |

| Acceleration and deceleration curve: | Two modes: linear acceleration and deceleration, S curve acceleration and deceleration; seven accelerating and decelerating time, time unit (min/sec) optional, the longest 6000 minutes | |

| DC braking: | DC braking starting frequency: 0~15.00Hz Braking time: 0~60.0 seconds Braking current: 0~80% | |

| Energy consumption braking: | Built-in energy consumption braking unit, externally connected braking resistor | |

| Pointing: | Pointing frequency range: 0.1Hz~50.00Hz, pointing acceleration and deceleration time: 0.1~60.0 seconds | |

| Built-in P: | can easily constitute a closed-loop control system | |

| Multi-speed operation: | Multi-speed operation can be realized by built-in PLC or control terminal Textile swing | |

| Frequency swing function: | Frequency swing function with adjustable preset frequency and center frequency | |

| Automatic voltage regulation (AVR) | When the grid voltage changes, the output voltage remains constant | |

| Automatic energy-saving operation | According to the load, the V/F curve is optimized automatically to achieve energy-saving operation | |

| Automatic current limiting | Automatic current limitation during operation to prevent frequent over-current fault trip | |

| Multi-pump constant pressure water supply control function | Connected with the water supply control board, the multi-pump constant pressure water supply control function can be realized. | |

| Communication function | Support four kinds of field bus: Modbus, Profibus, CANlink, CANopen | |

| Operational function | Operation command channel | Operation panel is given;Control terminal is given;Serial port is given;Three ways can be switched |

| Frequency setting channel | Keyboard analog potentiometer is given;Keyboard ▲ key is given;Function code number is given;Serial port is given;Terminal UP/DOWN is given; Analog voltage is given;Analog current is given;Pulse is given;Combination is given;Can be switched in a variety of given ways at any time | |

| Switch input channel | Positive and reverse instructions;8 programmable switch input, 35 functions can be set respectively. | |

| Analog input channel | 2 analog signal input, 4~20mA, 0~10V optional | |

| Analog output channel | Analog signal output, 4~20mA or 0~10V optional, can realize the output of set frequency, output frequency and other physical quantities | |

| Switch, pulse output channel | 2 programmable open-circuit collector output;2 relay output signal; 1 0 ~ 20KHz pulse output signal, to achieve various physical output | |

| Operation panel | LED digital display | can display the set frequency, output voltage, output current and other parameters |

| external instrument display | output frequency, output current, output voltage display and other physical quantity display | |

| Key locking | to achieve all the keys locked | |

| Parameter copy | using remote keyboard can achieve the function code parameters copy function between the inverter. | |

| Protection function | overcurrent protection; overvoltage protection; undervoltage protection; overheating protection; overload protection, etc. | |

| Optional parts | brake assembly; remote operation panel; remote cable; keyboard mounting seat, etc. | |

| Environment | Place of use | indoors, free from direct sunlight, no dust, corrosive gas, oil mist, steam, etc. |

| Sea wave height | less than 1000 meters (above 1000 meters to be reduced) | |

| Ambient temperature | -10°C~+40°C | |

| Humidity | less than 90%RH, no dew | |

| Vibration | less than 5.9 meters / second (0.6M) | |

| Storage temperature | -20°C~+60°C | |

| Protection level | P20 (in the state of the selected state display unit or keyboard) | |

| cooling method | forced air cooling | |

| Installation method | wall-mounted, cabinet installation | |

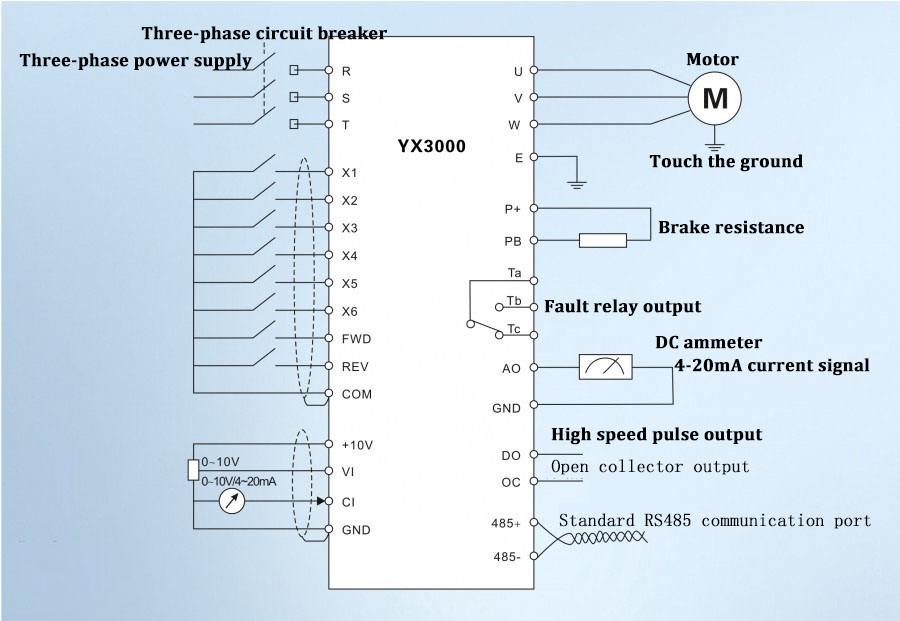

Basic wiring diagram

FAQ

Can you produce according to the samples or drawings?

Yes, we can produce by your samples or technical drawings. We can build the molds

What is the lead time?

For standard models, lead time is about 3~5 days after order confirmed and payment received.

For OEM orders, the delivery is about 2~3 weeks after data confirmed and payment received.

How to solve the quality problems after sales?

Take photos or videos of the problems and send to us.

We will make a satisfied solution for you within 24 hours after we confirm the problems.

X

X