♦Dual-core processor, hardware current loop,16KHz position loop and 16KHz speed loop helps to double the performance, compeared to the last generation.

♦Passed EtherCAT CTT test, SD20-E has better compatibility to work with different brands of PLC or automation controller.

♦Bidirectiona data transmission can reach 100Mbps. The min communication cycle is 250uS.

♦Thanks to the gain autotuning function and model feedforward control, no matter there is gain tuning command or not, it helps customers to easily make gain autotuning, and simple commissioning.

SCH-SD20-E Series Servo Drives

SD20-E Series Servo Drives is a high performance drive particularly suitable for general use. It has a 3.2kHz frequency response, which could meet the wide range of customer's requirement.

Widely used in CNC machine tool, packaging machine, textile machine, wooden machine, etc

Technical Specification

| Item | Content | ||

| Input power supply |

S2/T2 | 220VAC-10~+10% 50/60Hz | |

| T3 | 380VAC -10~+10% 50/60Hz | ||

| Control mode | 1.Profile position control mode (PP) 2.Profile velocity mode (PV) 3.Profile torque mode (PT) 4.Homing mode (HM) 5.Cycle synchronous position mode (CSP) 6.Cycle synchronous velocity mode (CSV) 7.Cycle synchronous torque mode (CST) |

||

| Energy-loss brake | Built-in or External brake resistor (external brake alternative M1 frame and above 7.5kW drive:No built-in brake resistor. Other models:Built-in brake resistor |

||

| Control feature |

Control type | PMSM motor | |

| Response frequency | PMSM servo:1.2KHz | ||

| Baud rate | ±0.01%(load 0~100%) | ||

| Speed fluctuation | PMSM:±0.01%(VC,load fluctuation 0 to 100%) | ||

| Speed ratio | 1:10000 | ||

| EtherCAT specification |

Communication protoco | EtherCAT protocol | |

| Support service | CoE (PDO,SDO) | ||

| Synchronous method | DC distributed clock | ||

| Physical layer | 100BASE-TX | ||

| Transmission speed | 100 Mbit/s(100Base-TX) | ||

| Duplex mode | Full duplex | ||

| Transmission media | CAT5E class and above shielded cable | ||

| Transmission distance | The distance between 2 nodes <100M (good surroundings and cables) |

||

| Slave station | Max 65535 (lower than 100 in practical use) | ||

| Synchronization jitter | <lus | ||

| Minimum communication cycle |

500us | ||

| Input signal | Control input | Servo enabled,alarm reset,command pulse clear,command pulse prohibited,forward prohibited,reverse prohibited,forward torque imit,reverse torque limit,internal speed selection,internal position triggered,origin/mechanical origin searching triggered,zero speed clamp,probe etc | |

| Encoder | 1.Absolute value encoder 2.Incremental encoder 3.Rotary transformer |

||

| Output signal |

Control output | Servo ready,servo alarm,positioning reach,speed reach,electromagnetic brake output,rotation detection,speed limit,homing completed,torque limit etc. | |

| Encoder signal frequency dividing outpu |

1.Encoder Z phases open-collector output; 2.Phase -A,-B:frequency-division differential output(not isolated,any frequency-division ratio Phase-Z is not frequency-division output 3.Z pulse time extended function. |

||

| Position contro |

Input mode | EtherCAT communication set,internal register: high-speed pulse input | |

| Electronic gear ratio | 1.0.01≤B/A≤100 2.Support 2 groups of electronic gear,which can be selected or switchover by users |

||

| Acceleration/Deceleration | The setting range of accel/decel time is 1~30000ms (from 0 accelerated to rated speed) |

||

| Communication | 1.RS485/RS232 communication port is connected with PC,to set control parameters and to monitor servo 2.Support EtherCAT bus |

||

| Parameter setting |

Keypad | Use 4 keys to set parameter,which is displayed by 5 LEDs. | |

| PC/PLC | PC/PLC software can be used to set servo parameter through RS485 communication interface |

||

| Monitor function | Output current,PN voltage,motor speed,motor feedback pulse motor feedback revolution,given pulse,given pulse error,given speed,given torque etc | ||

| Protection function | Main circuit overvoltage,undervoltage,overload,overcurrent encoder error,overspeed,abnormal pulse control command emergency stop,servo overheat,main-circuit power phase-loss regeneration brake error,position,over position control,lithium battery alarm,Sync.loss,network initialization failure,sync cycle setting error,sync.cycle excessive error etc |

||

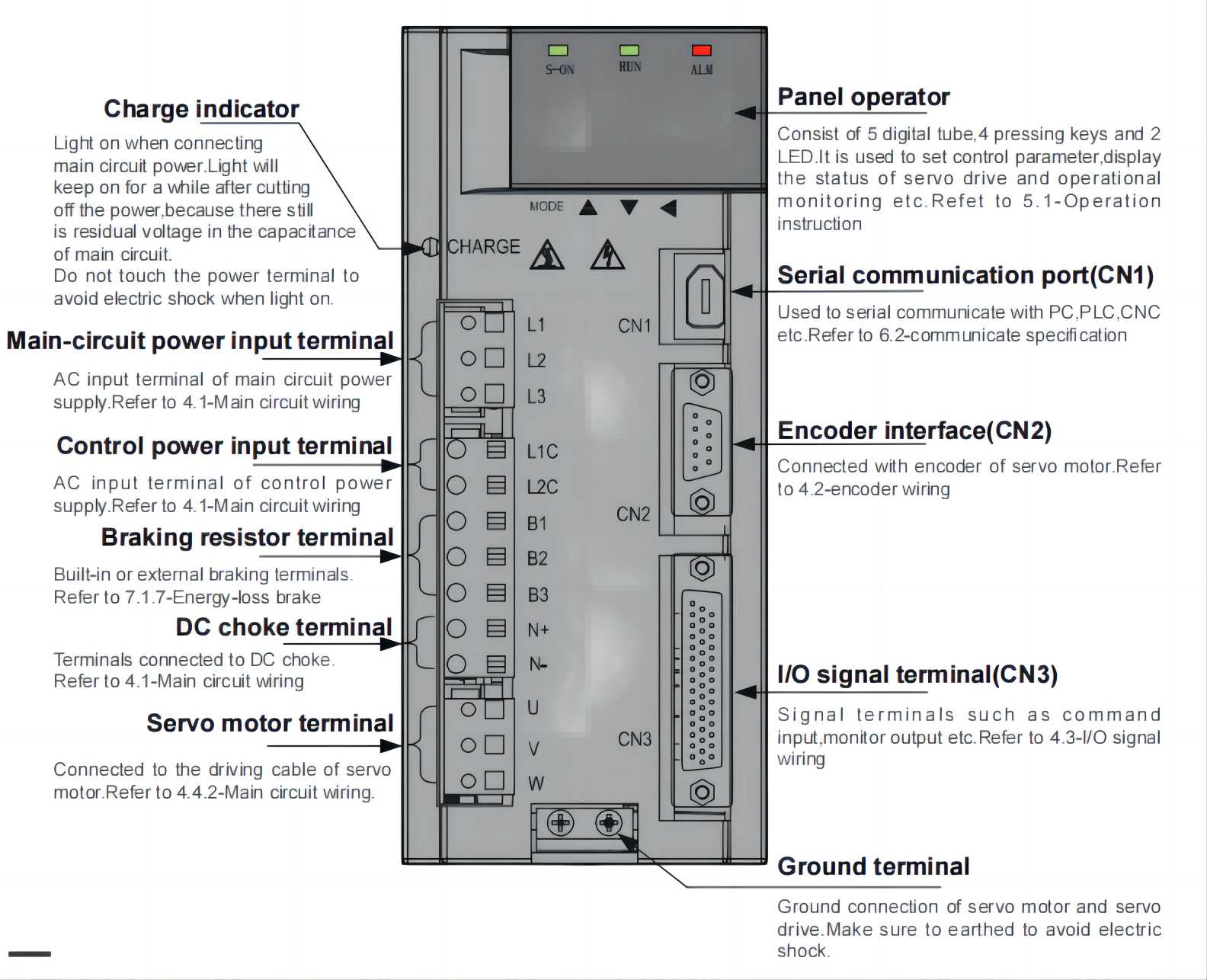

Drive component

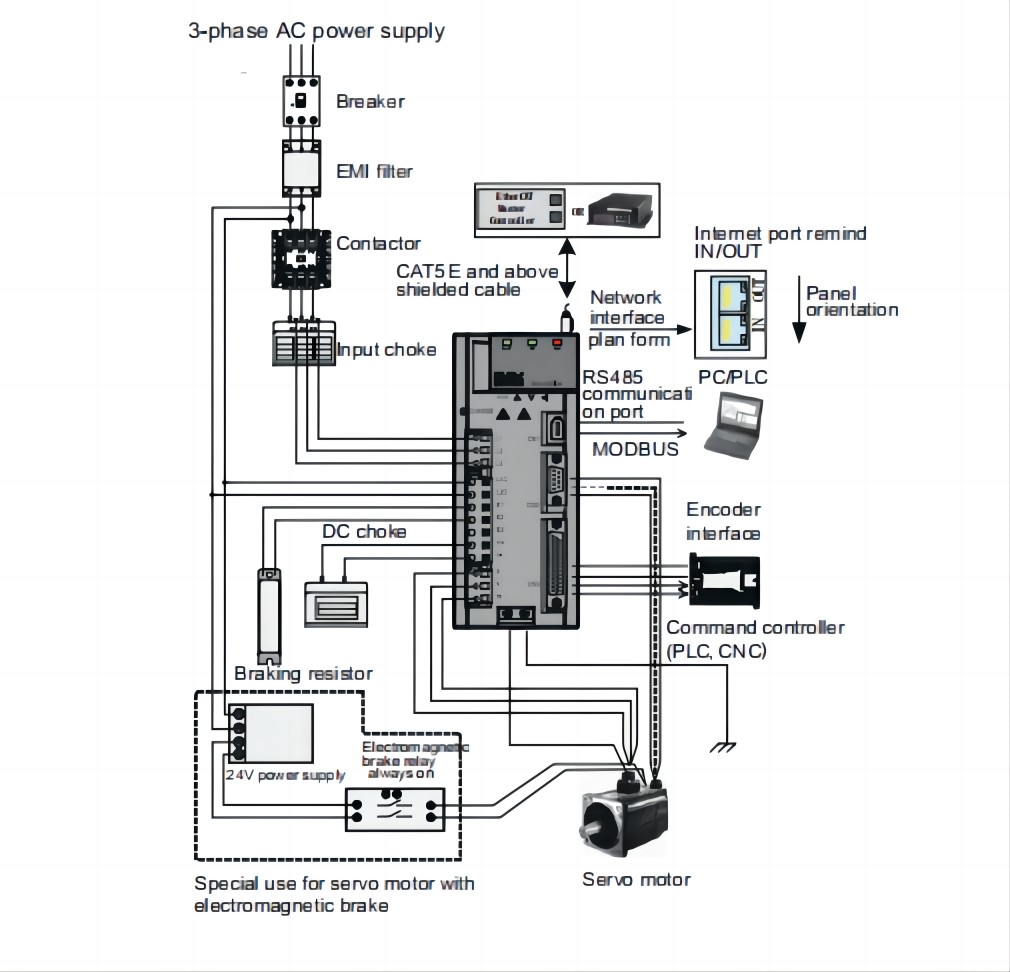

SD20-E connection to peripheral devices

FAQ

Can we accept samples customized?

No problem for samples order, and welcome your testing before your big order.

OEM and ODM are available?

Yes, we accept customized products

Can I get a lower price if I order large quantities?

Yes, Cheaper prices with bigger size orders, please contact us and we will give you a quatation.

X

X