Ore sorting is used in the early stages of mineral processing and essentially involves separating high-grade from low-grade materials. The technology behind ore sorting has evolved, meaning the process can now operate at higher throughputs and accuracy. Given these advances in technology, the question is: is ore sorting suited to your operation?How dose ore sorting help you ?

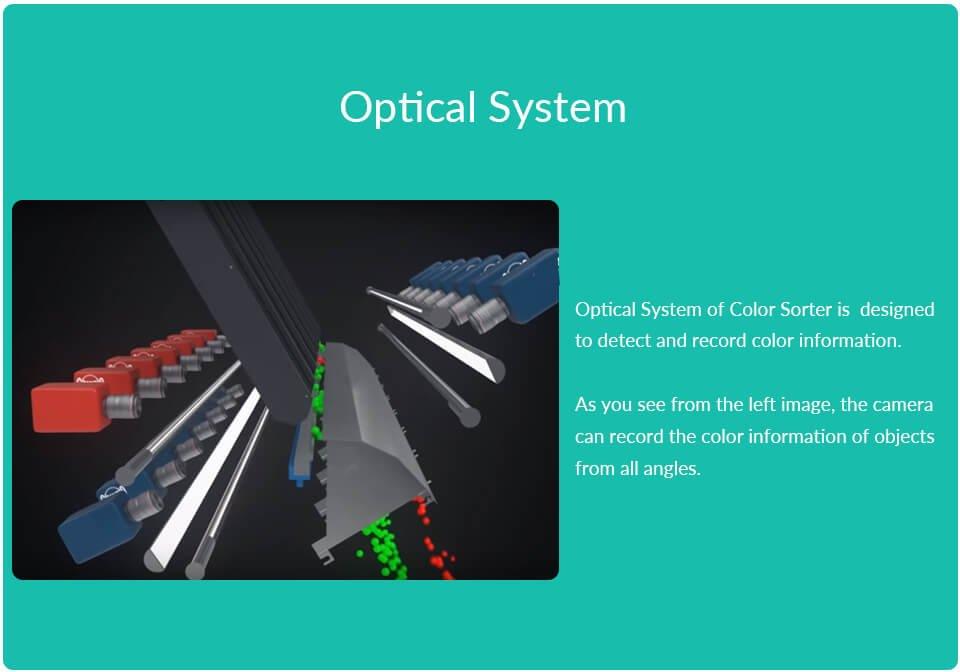

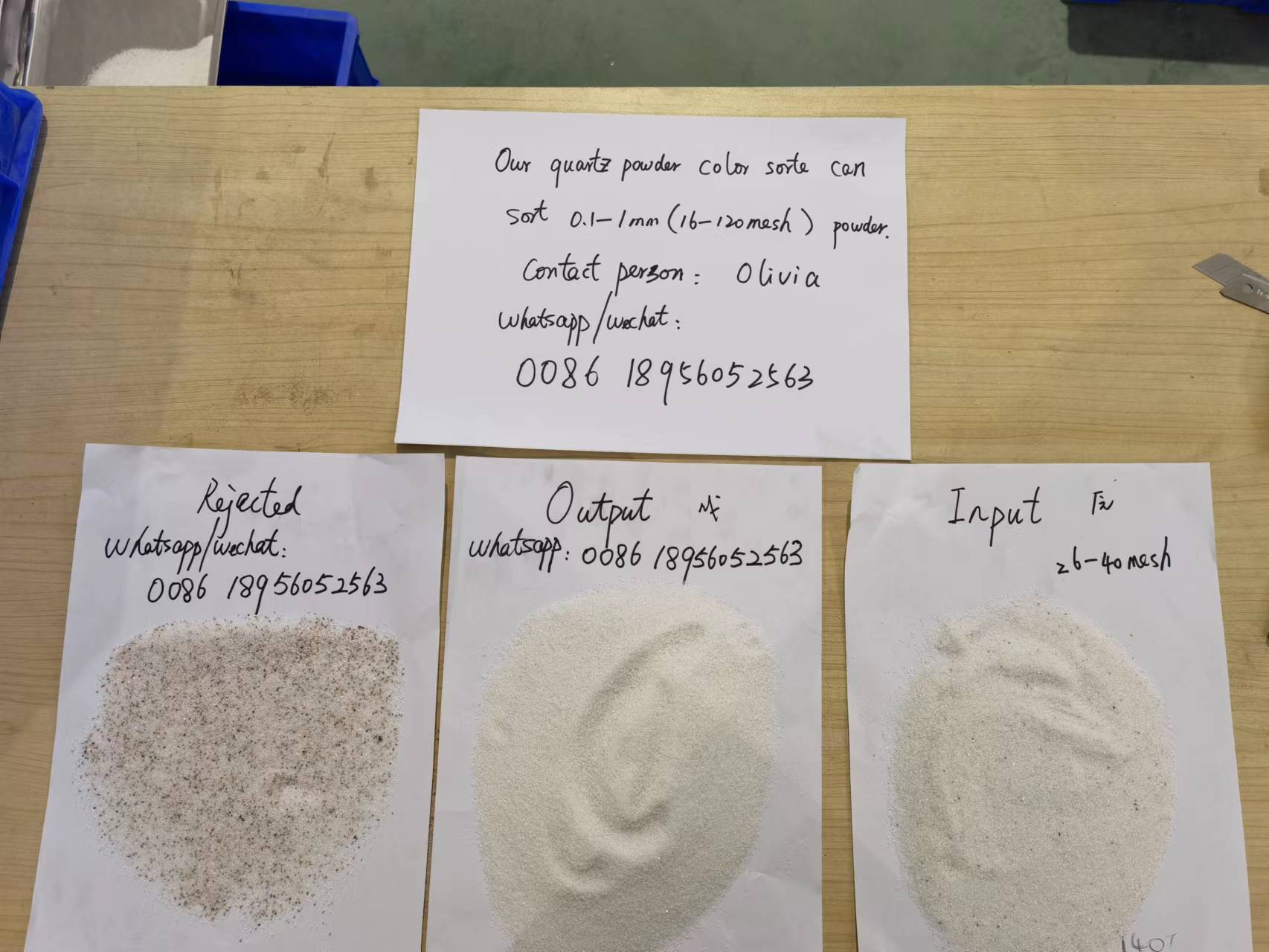

Silica quartz powder color sorter machine can remove the discoloured powder like the black / yellow out from good one .Suitable size of the powder around 0.1-1mm (26-120 mesh) for sorting.Normally natural silica having a purity of more than Sio2 99%. This quartz silica powder comes in a very snow white color. The whiteness in A grade is more than 95%.Silica sands powder is suitable for all ceramic applications like body, engobe and glaze composition. it is also used in the paint industry, foundry industries, and other applications.

How dose ore sorting help you ?

Ore sorting is a process of separating valuable minerals from waste rock, based on their physical and chemical properties. Ore sorting can help you in various ways, such as:

1.Improved Efficiency: Ore sorting can significantly improve the efficiency of the mining process. By separating valuable minerals from waste rock early in the mining process, it reduces the amount of material that needs to be processed, thereby reducing the processing time and costs.

2.Increased Yield: Ore sorting can also increase the yield of the mining operation. By removing waste rock early in the process, it ensures that more valuable minerals are recovered, thereby increasing the overall yield of the mining operation.

3.Improved Grade Control: Ore sorting can also improve the grade control of the mining operation. By accurately separating valuable minerals from waste rock, it ensures that the ore fed into the processing plant is of a consistent grade, which can help to improve the quality of the final product.

4.Reduced Environmental Impact: Ore sorting can help to reduce the environmental impact of the mining operation. By removing waste rock early in the process, it reduces the amount of material that needs to be processed, thereby reducing the energy consumption and emissions associated with the processing plant.

5.Enhanced Safety: Ore sorting can also enhance the safety of the mining operation. By removing waste rock early in the process, it reduces the amount of material that needs to be handled and processed, thereby reducing the risk of accidents and injuries.

6.In summary, ore sorting can help you to improve the efficiency, yield, grade control, environmental impact, and safety of your mining operation. By implementing ore sorting technology, you can reduce costs, increase profitability, and make your mining operation more sustainable.

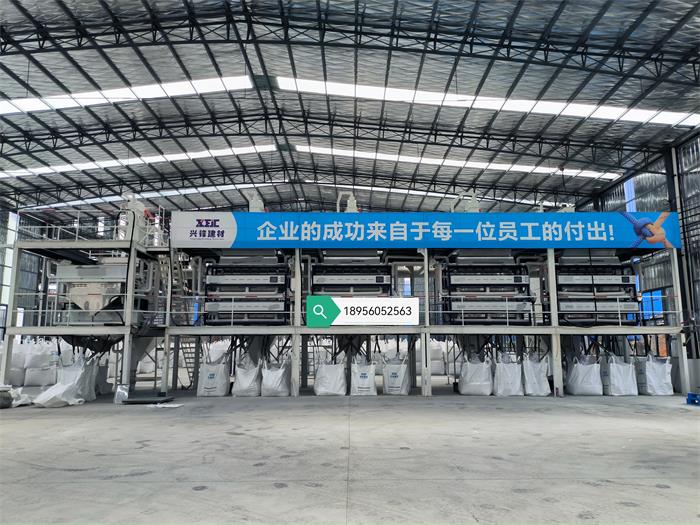

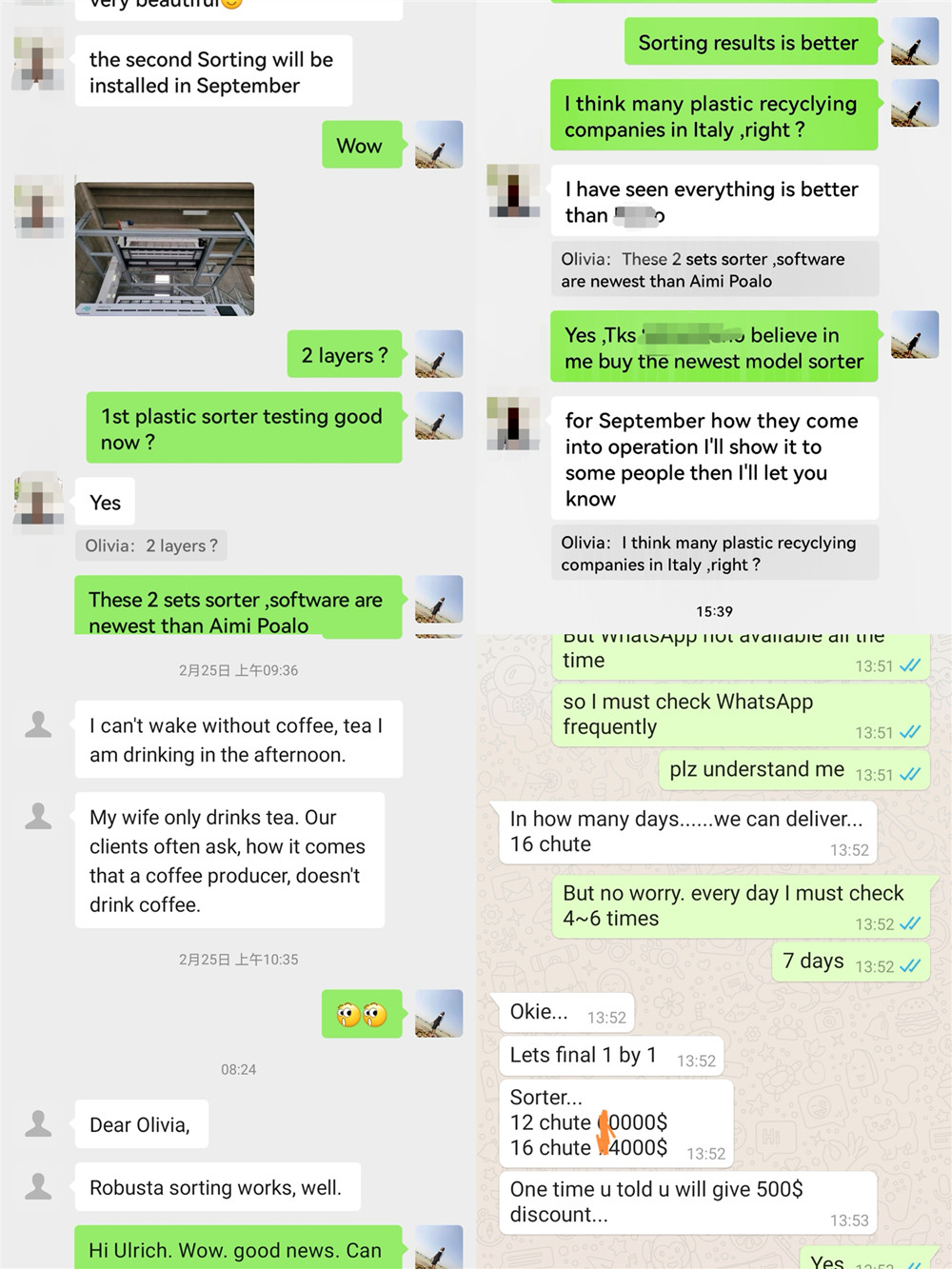

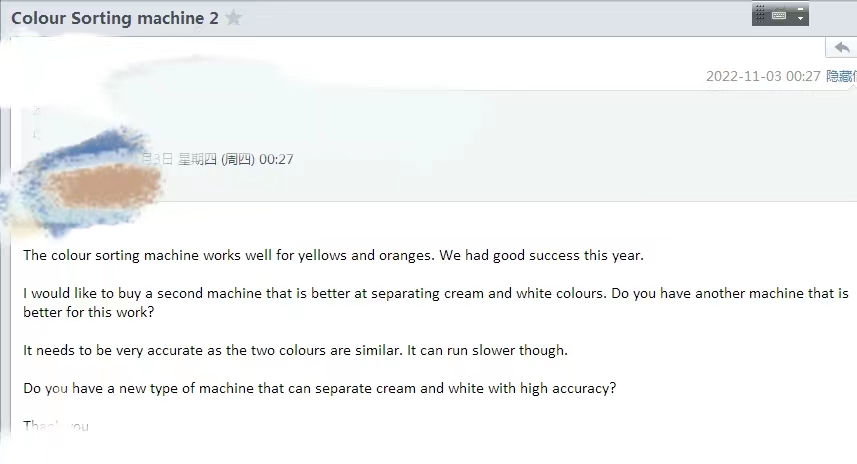

CUSTOMERS FEEDBACK

We have many installation cases and working videos. Please contact us freely if you need.

X

X