Grain colour sorter

Provide efficient sorting solutions for various types of grain

Mihoshi Grain Multi purpose Color Sorter is widely used to meet your different needs. It is suitable for sorting and grading miscellaneous grain materials such as corn, wheat, soybeans, red beans, mung beans, lentils, white kidney beans, milky beans, broad beans, chickpeas, peanuts, quinoa, millet, sesame, oats, barley, barley, sorghum, etc. Efficient removal of impurities such as discolored particles, moldy particles, soil blocks, small stones, glass, desiccants, etc. It has the characteristics of a stable high-precision sorting system, high production, energy saving, simple operation, convenient use, and long service life.

Product Introduction

Suitable for grain sorting and grading, equipped with infrared sorting system sorting machine models, ultraviolet sorting system machine models, and AI deep learning technology sorting models, it can remove impurities such as discoloration, mold, soil blocks, stones, glass, plastics, desiccants, etc.

Adopting a stable high-precision sorting system, the impurity sorting effect is good. Double the production of cutting and mixing. High yield, energy-saving, simple operation, convenient use, and long service life.

Application Field

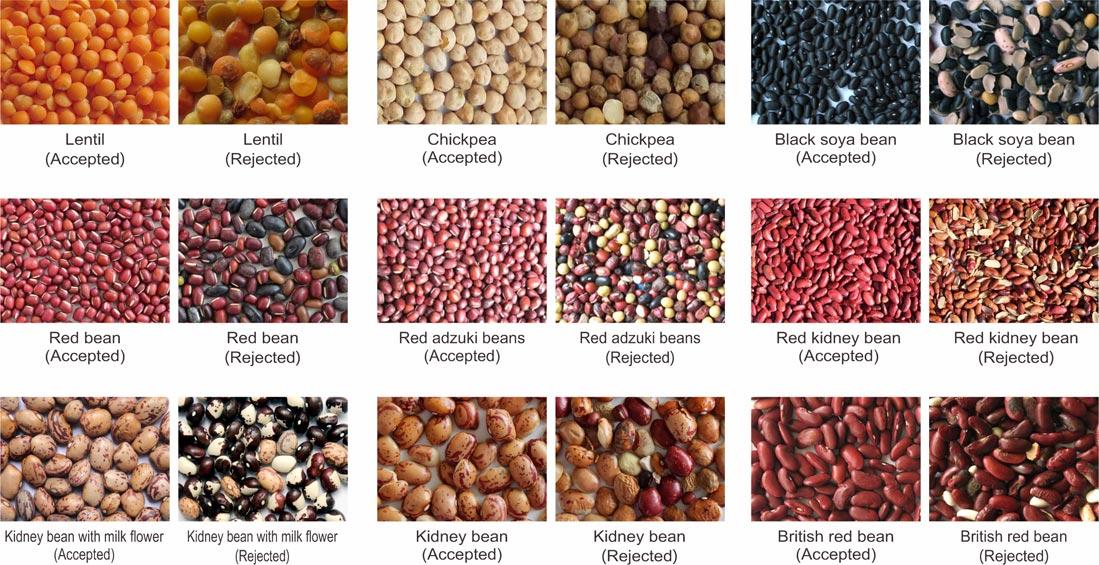

Applied to the sorting of corn, wheat, soybeans, red beans, mung beans, lentils, white kidney beans, milky beans, broad beans, chickpeas, peanuts, peanuts, quinoa, millet, sesame, oats, barley, highland barley, sorghum and other miscellaneous grain materials.

Product Specificities

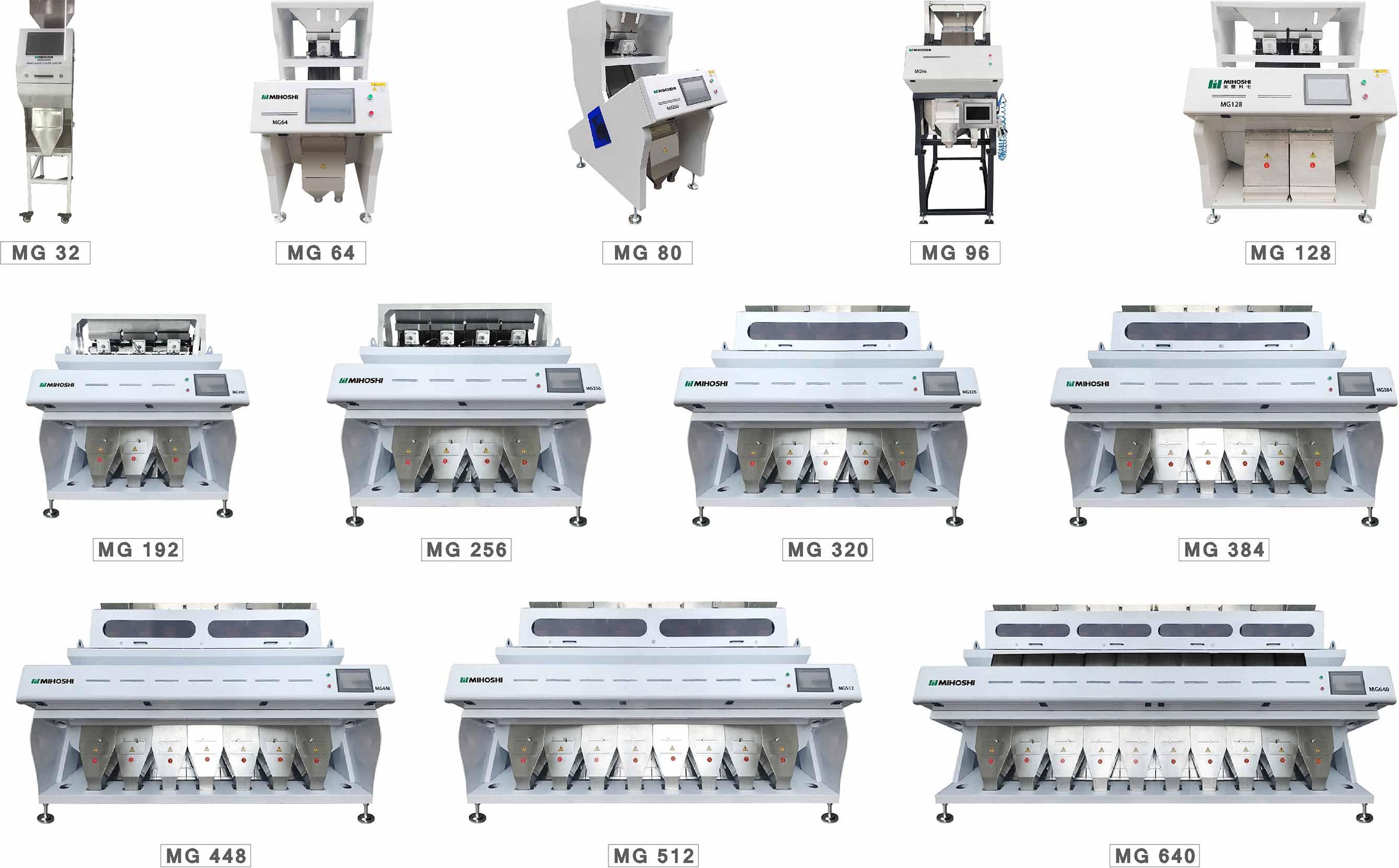

Product models of Chutes color sorter (MG Series)

Sorting Examples

Technicial Specifications

| Product model |

Capacity (T/h) |

Accuracy (%) |

Voltage (V/Hz) |

Power (kW) |

Air pressure (Map) |

Air consumption (L/min) |

Weigh t(Kg) |

Dimension (mm) |

| MG32 | 0.2-0.5 | >99.99% | 220/50 | 0.5-0.8 | 0.6-0.8 | 0.1-0.3 | 120/180 | 590X1504X1760 |

| MG64 | 0.8-1.6 | >99.99% | 220/50 | 0.8-1.5 | 0.6-0.8 | 0.3-0.8 | 300/350 | 880X1504X1760 |

| MG80 | 1-2 | >99.99% | 220/50 | 1-1.8 | 0.6-0.8 | 0.3-0.8 | 350/400 | 900X1504X1760 |

| MG96 | 1-3.5 | >99.99% | 220/50 | 1.2-1.8 | 0.6-0.8 | 0.4-0.9 | 300/400 | 1550X940X1750 |

| MG128 | 2-6 | >99.99% | 220/50 | 1.3-2.2 | 0.6-0.8 | 0.5-1.0 | 700/860 | 1314X1504X1760 |

| MG192 | 3-9 | >99.99% | 220/50 | 1.5-2.5 | 0.6-0.8 | 0.8-1.5 | 950/1000 | 1650x1504X1760 |

| MG256 | 4-12 | >99.99% | 220/50 | 1.8-3 | 0.6-0.8 | 1.0-2.0 | 1100/1200 | 1986X1504X1760 |

| MG320 | 5-15 | >99.99% | 220/50 | 2.2-3.7 | 0.6-0.8 | 1.3-2.1 | 1280/1350 | 2322x1504X1760 |

| MG384 | 6-18 | >99.99% | 220/50 | 3.6-4.5 | 0.6-0.8 | 2.0-3.5 | 1400/1500 | 2658X1504X1760 |

| MG448 | 7-21 | >99.99% | 220/50 | 4.1-5.5 | 0.6-0.8 | 2.5-4.3 | 1500/1600 | 2994x1504X1760 |

| MG512 | 8-24 | >99.99% | 220/50 | 4.7-6 | 0.6-0.8 | 3.0-4.5 | 1700/1800 | 3330X1504X1760 |

| MG640 | 10-30 | >99.99% | 220/50 | 4.5-7.5 | 0.6-0.8 | 5.0-6.5 | 2000/2250 | 3666X1504X1760 |

| MG768 | 12-38 | >99.99% | 220/50 | 5.2-8.8 | 0.6-0.8 | 7.0-8.5 | 2500/2600 | 4200x1504X1760 |

Installations Case

X

X