Metal Roof Ridge Cap Machine/Metal Ridge Cap Machine/Roofing Ridge Cap Machine/Metal Ridge Cap Roll Forming Machine is a smart roll former that used for manufacturing various types of metal ridge caps that fix on roofing system top.

Description:

Metal Roof Ridge Cap Machine/Metal Ridge Cap Machine/Roofing Ridge Cap Machine/Metal Ridge Cap Roll Forming Machine:

It can be made as per desired requirements and can be fabricated from various material thicknesses and in almost any length. With highly cutting length accuracy, accurate dimension forming automatically, the forming line capable well improved customer production capacity.

Working Procedure:

Uncoiling– Pre-shearing if inecessary– Roll Forming Machine– Cutting– Collecting

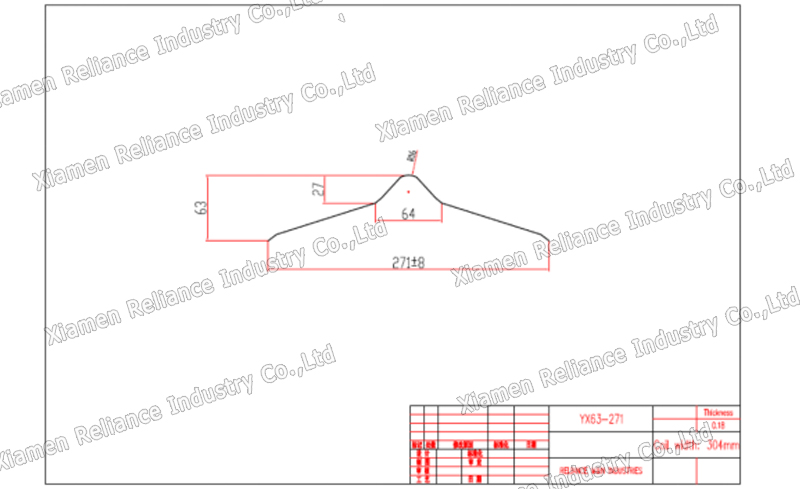

Profile:

Technical Details:

|

The Line’s Specifications |

|

|

Weight |

About 22000kgs |

|

Whole line’s dimension |

About 8m x 0.5m x 1.2m (length x width x height) |

|

Color |

Main color: blue |

|

Warning color: yellow |

|

|

Suitable Raw Material |

|

|

Material |

Galvanized, Galvalume Coils, PPGI |

|

Thickness |

0.17-0.25mm |

|

Yield Strength |

550Mpa |

|

Main Technical Parameters |

|

|

Quantity of forming rollers stations |

About 10 |

|

Diameter of forming rollers shafts |

60mm |

|

Roll Forming Speed |

18m/min |

|

Forming rollers material |

40Cr material, CNC lathe, hard chrome coated |

|

Cutter material |

Cr12 mould steel, with quenched treatment |

|

Controlling system |

Combined with: PLC (Siemens), Touch Screen (Siemens), Inverter (Schneider), Encoder (Omron), etc |

|

Electric Power requirement |

Main motor power: 5.5kw |

|

Hydraulic unit motor power: 4kw |

|

|

Electric voltage |

According to customer’s requirement |

|

Main Components |

|

|

Decoiler (manual and automatic for options) |

1 set, 5TonX600mm |

|

Pre-Cutting Device |

1 set |

|

Roll Forming system |

1 set |

|

PLC control box |

1 set |

|

Hydraulic unit |

1 set |

|

Run outs tables |

1 set |

Metal roof ridge cap machine:

Ridge Cap Roofing Machine:

X

X