Tube Sealing Machine can perform the sealing, batch number embossing (include manufacture date) automatically. It’s ideal equipment for sealing for cosmetic, pharmacy, foodstuff and bond industries.

This Ultrasonic Tube Sealing Machine is widely used in pharmaceutical, cosmetic, food and chemical industries etc., it is

applicable in various plastic compound soft tube, plastic soft tube which pack all kind of Such as ointment, adhesives, AB glue, Neoprene, epoxy glue, skin cream, hair cream, boots oil, toothpaste and else liquid, lotions and cream etc.

Compared with heat sealing, the ultrasonic tube sealing has the following advantages:

* Fast Sealing, save time

* Sealing is nice looking, different shape sealing

* Lower power consumption, energy saving

* Recommend Machine: Toothpaste Filling Machine

* Because the product is updated quickly, please ask us the type of machine before placing an order

Working Process:

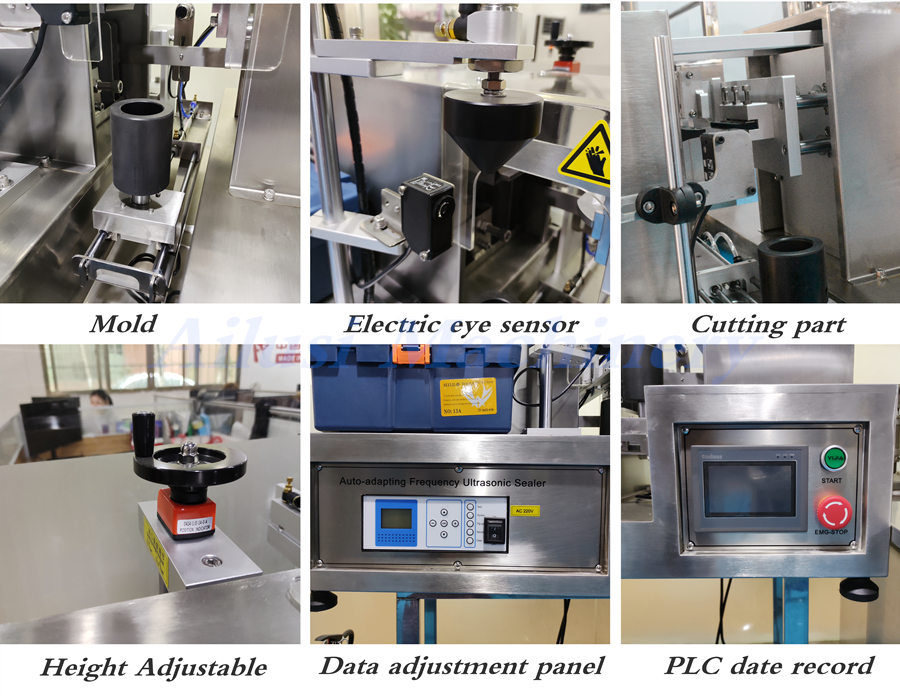

Tube loading by hand -->Color mark orientation -->Ultrasonic sealing and date coding-->Cutting

|

Machine Name

|

Soft tube sealing machine

|

|

Control type

|

Advanced PLC control

|

|

Power supply

|

AC 110V/220V

|

|

Sealing diameter

|

5~50mm

|

|

tube height

|

10~250mm

|

|

Production capacity

|

about 20-30 pcs/min

|

|

Material

|

304 stainless steel machine body

|

Application:

It can be used for pharmaceuticals, food products, cosmetics, and chemicals.

*Cosmetic: Face Cleaner, Hand Cream, Eye Cream, Sunscreen, Acne cream, Hair removal cream, Body lotion, Whitening Cream, etc.

* Food: Mayonnaise, Cheese, Peanut butter, etc.

* Pharmaceuticals: Ointment, Unguent, Paste, Toothpaste etc.

* Chemicals: Painting, Shoe polish etc.

Package & Delivery:

To ensure the quality of our service, we will follow the standard package upon delivery:

1. All products before delivery should be tested by assembly and commissioning engineers. Our salesman need to send the tested video to the customer to ensure working well of the machines. Precision parts need to be packed in film or carton.

2. All products are packed in wooden boxes. Firmly fix the edge of the foot of the equipment to adapt the machine to the requirements of loading and uploading.

Our Servers:

Ailusi provide Turn-key Project Service to customer.

1. Factory Layout design;

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, Maintenance service.

X

X