JIS 10K Globe valve also known as the door valve, belongs to the forced sealing valve, so when the valve is closed, must apply pressure to the disc, in order to force the sealing surface leakage.When the medium under the disc into the valve, the operating force to overcome the resistance, is the friction of the valve stem and packing and by the pressure of the medium produced by the thrust, the force to close the valve is greater than the force to open the valve, so the diameter of the valve stem to be large, otherwise the valve stem bending fault will occur.

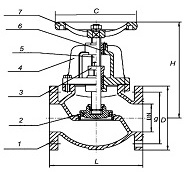

JIS 10K Cast Iron Flange Globe Valve

JIS 10K Globe valve also known as the door valve, belongs to the forced sealing valve, so when the valve is closed, must apply pressure to the disc, in order to force the sealing surface leakage.When the medium under the disc into the valve, the operating force to overcome the resistance, is the friction of the valve stem and packing and by the pressure of the medium produced by the thrust, the force to close the valve is greater than the force to open the valve, so the diameter of the valve stem to be large, otherwise the valve stem bending fault will occur.According to the connection mode is divided into three kinds: flange connection, screw connection, welding connection.From the appearance of the sealed valve, the flow of the globe valve media will be changed from the upper disc into the valve chamber, then under the action of media pressure, the force to close the valve is small, and the force to open the valve is large, the diameter of the valve stem can be reduced accordingly.At the same time, under the action of the medium, this form of the valve is more rigorous.China's valve "three to" has been stipulated that the flow of the globe valve, all adopt from top to bottom.When the globe valve opens, the opening height of the disc is 25% ~ 30% of the nominal diameter.The flow rate has reached the maximum, indicating that the valve has reached the full open position.So the full open position of the globe valve should be determined by the stroke of the disc.

|

Application |

|

|

1 |

Face to face is according to JIS B2002 |

| 2 | Flange drilled is according to JIS B2012 |

|

Test |

|

| Working pressure | 10K |

| Shell pressure | 2.1Kgf/cm² |

| Seat pressure | 15.0Kgf/cm² |

|

Main Prats and Materials |

||

| Number | Part Name | Material |

| 1 | Body | Cast Iron (FC200) |

| 2 | Disc | Bronze/Cast Iron |

| 3 | Gland | Cast Iron |

| 4 | Bonnet | Cast Iron (FC200) |

| 5 | Stem | Stainless Steel/Cast Brass (Mn) |

| 6 | Yoke Nut | Carbon Steel |

| 7 | Hand Wheel | Cast Iron |

|

Main Dimensions |

|||||

|

Norminal diameter |

L | H | D | g | C |

| 50 | 210 | 270 | 130 | 105 | 160 |

| 65 | 250 | 300 | 155 | 130 | 180 |

| 80 | 280 | 310 | 180 | 145 | 180 |

| 100 | 340 | 360 | 200 | 165 | 224 |

| 125 | 410 | 390 | 235 | 200 | 250 |

| 150 | 480 | 445 | 265 | 230 | 280 |

| 200 | 570 | 530 | 320 | 280 | 315 |

Packing & Delivery :

Packing Details : all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details : Generally it is 5-10 days if the goods are in stock. or15-30 days if the goods are OEM or not

enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45days.

X

X