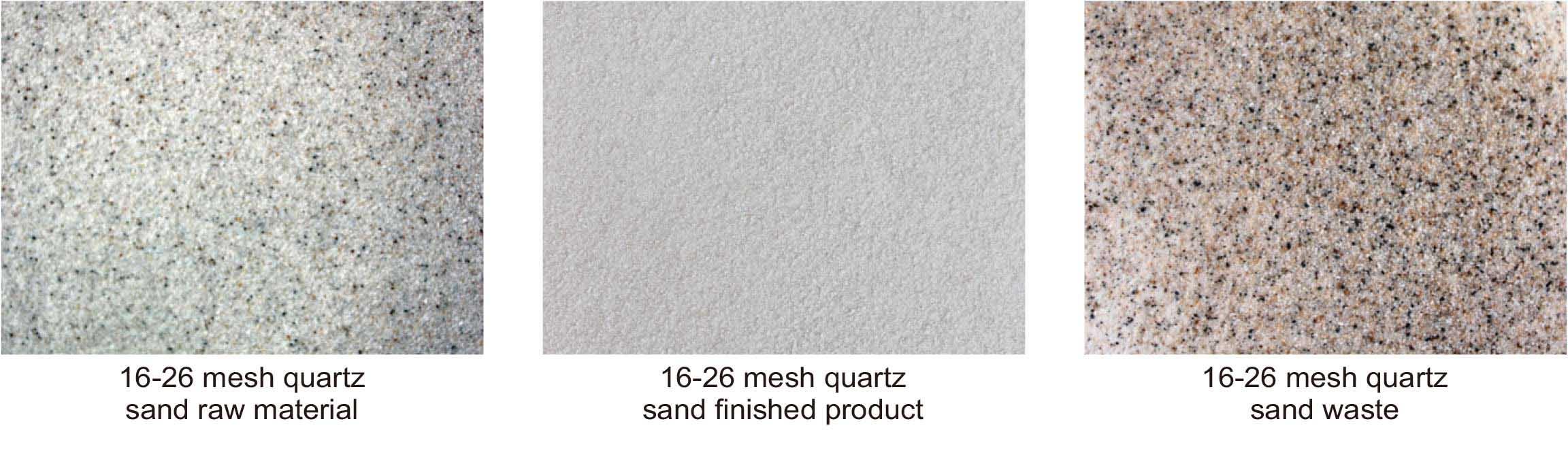

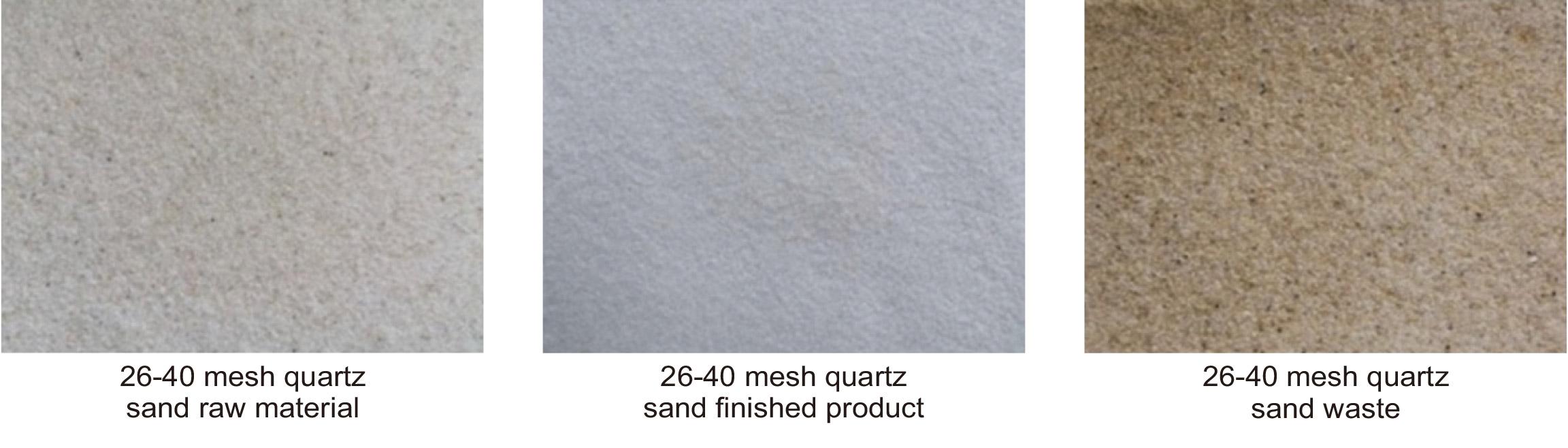

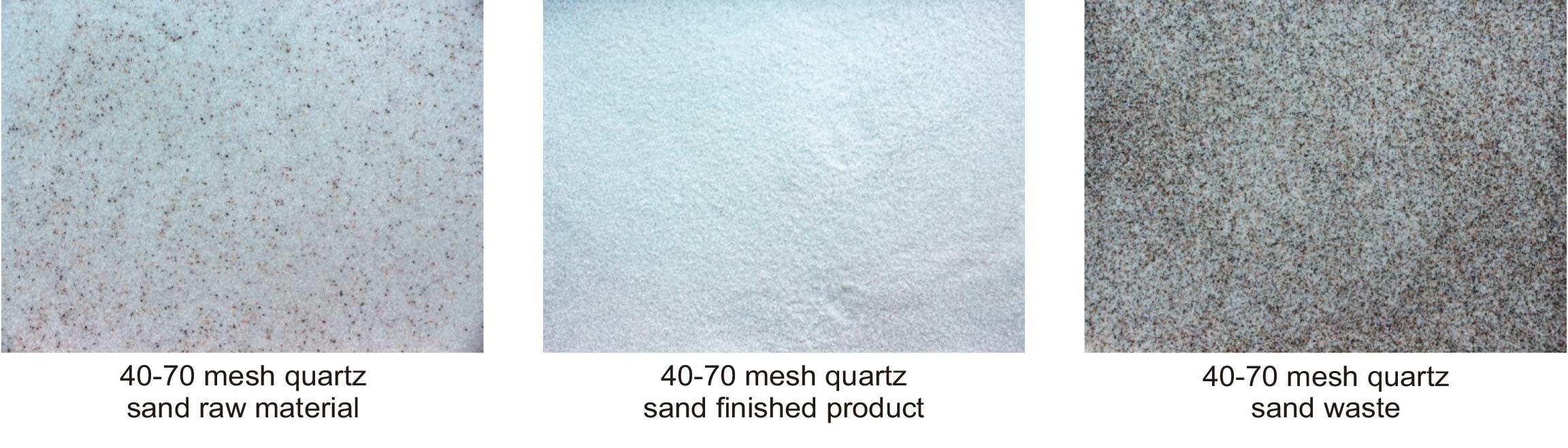

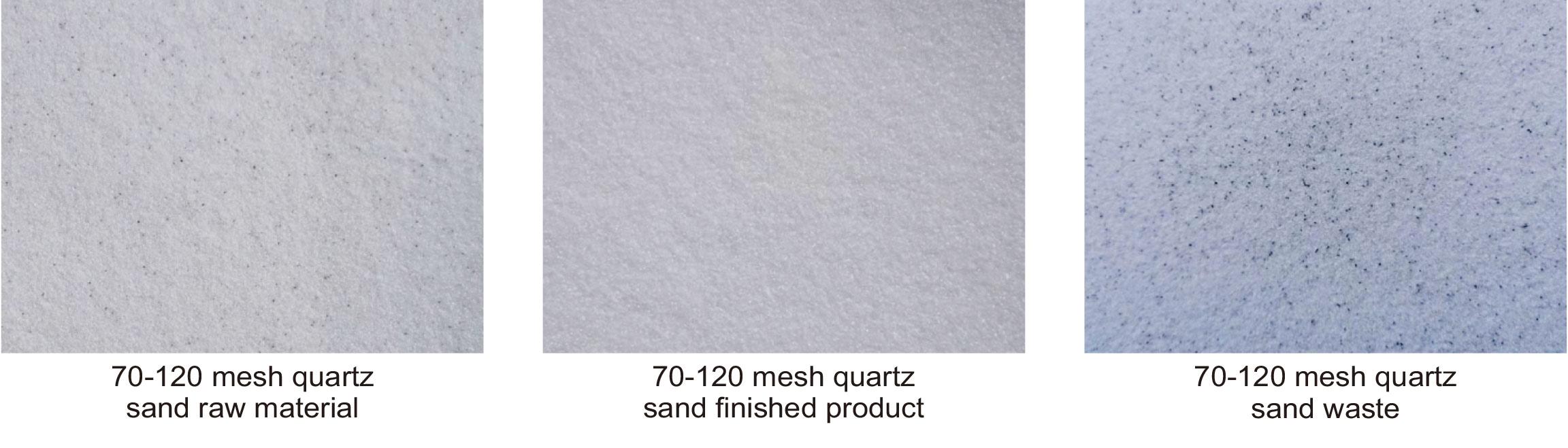

◀ Quartz stone particle color selection machine color selection range is large, the minimum optional 16 mesh, themaximum can choose 80 mm, quartz sand color selection machine color selection range 16-120 mesh.

◀ The equipment has wide versatilty, the same set of color separator can color quartz, silica, potassium feldsparcalcite,perite, glass, barte, fluorite, kaoin, calcium cartbonate, dolomite and other hundreds of non-metalic ores.

◀ Support material mixing selection range is large, 1-5mm can be mixed selection, 5-60mm can be mixedselection,compared with similar equipment has a very unique advantage.

◀ The stnucture of ore particle color separator is double track free fall type feeding, with high precision of colorselection, large output, less good matenial out ratio, high rate of selected products, low comprehensive powerconsumption and very hiah cost peromance.

◀ The sinucture of auarz sand color separator is double-laver free falina matenal, reduce the trouble caused byslide way materal, high color selection accuracy, low strip ratio.

◀ Strong resistance to extemal interferenoe, color selection effect is not affected by the extemmal environment andchange.

◀ 70% of the parts are purchased from intemational first-line brands, and the senvice ife of the whole machinecan reach 20 years.

◀ After the wamanty period, low maintenance costs.

◀ The equipment perfomance is very stable, the equipment after years of use, the color selection effect isconsistent.

◀ Simple operation, easy to leam and use, only half an hour training can be skiled operation.

Core technology

1、The quartz particle color sorter has a wide color selection range, with a minimum selection of 16 mesh and a maximum selection of 6 cm.

2、This equipment has wide versatility, and the same color sorter can color select hundreds of non-metallic ores such as quartz, silica, potassium feldspar, calcite, perlite, glass, barite, fluorite, kaolin, calcium carbonate, dolomite, etc.

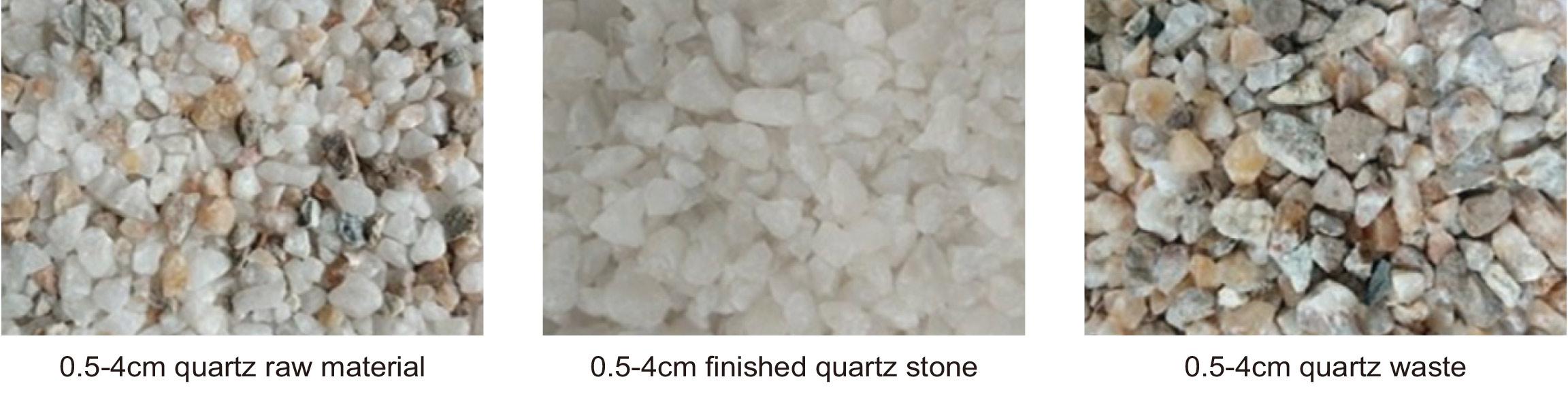

3、The range of material mixing and selection is wide, with 0.1-0.5 cm for mixing and 0.5-6 cm for mixing, which has unique advantages compared to similar equipment.

4、The structure of the quartz particle color sorting machine is a double-layer crawler free fall type feeding, which has high color sorting accuracy, large output, less good material to be carried out, high finished product rate, low comprehensive power consumption, and very high cost-effectiveness.

Product Introduction

Suitable for the mineral industry and ore processing enterprises, we have launched multiple models of ore color sorters, with stable products, reliable performance, leading technology, and precise sorting. Suitable for sorting and grading various types of ores.

Application Field

Suitable for the sorting and grading of multiple types of ores, including quartz, quartz sand, potassium feldspar, kaolin, silica, fluorite, perlite, barite, diamond, gold ore, tungsten ore, copper ore, manganese ore, hematite ore, magnesite ore, etc.

Product Specificities

Product models of Chutes color sorter

Technicial Specifications

Comprehensive technical parameters

| Product nema | Product model |

Number of channels |

Capacity (T/h) |

Voltage (V/Hz) |

Power (kW) |

Air pressure (Map) |

Weigh t(Kg) |

Dimension (mm) |

| KS4-1200-KS4-1950 | Double layer wet selection | 512-768 | 7-20 | 220/380(50Hz) | 6.5-10 | 0.5-0.8 | 2450-2830 | 4907x2410X2727 |

| KS4-1200-KS4-1950 | Double layer dry selection | 512-768 | 4.5-20 | 220/380(50Hz) | 6.5-10 | 0.5-0.8 | 2100-2600 | 3796x1880X2289 |

| KS2-1200 | Single layer wet selection | 256 | 6-15 | 220/50Hz | 4.5 | 0.5-0.8 | 1500 | 2680x1820X1596 |

| FLD6-128 |

16-140 mesh quartz sand dedicated |

1536 | 1.5-6 | 220/50Hz | 5..5 | 0.2-0.3 | 2500 | 2690x1820X2590 |

| MXLD300 | Monolayer | 64 | 0.5-0.8 | 220/50Hz | ≤3.0 | 0.6-0.8 | 500±25 | 3098x820X1660 |

| MXLD600 | Monolayer | 128 | 0.7-1.0 | 220/50Hz | ≤3.5 | 0.6-0.8 | 650±50 | 3098x1130X1660 |

| MXLD1200(AI) | Monolayer | 256 | 1.0-2.5 | 220/50Hz | ≤5.5 | 0.6-0.8 | 1250±50 | 3098x1750X1715 |

| MXLS1200(AI) | Double-deck | 256 | 1.5-3.0 | 220/50Hz | ≤9.5 | 0.6-0.8 | 1250±50 | 3098x1750X1715 |

| MXLS1870(AI) | Double-deck | 768 | 4.0-6.5 | 220/50Hz | ≤11.0 | 0.6-0.8 | 3000±50 | 5000x2760X2800 |

Product Specificities

Installations

Our strengths

X

X