♦Circuit design from the power part of the selection of high quality power module

♦The patented acoustic wave intelligent technology software cancarry out intelligent echo analysis without any debugging and other special steps.

♦This instrument is a non-contact instrument, no direct contact with the liquid.

♦All input and output lines of the instrument have the protectionfunction of lightning protectionand short circuit prevention.

Water Tank Fuel Oil Ultrasonic Liquid Level Sensor

All-in-one ultrasonic liquid level meter (range and line length can be determined) ,Water Level Ultrasonic Sensor

Technical Specification

| Product name | All-in-one ultrasonic liquid level meter (range and line length can be determined) | ||

| Measuring range | 0~20m(selected according to the measured range) | ||

| Ranging accuracy | 0.3%(standard condition) | ||

| Instrument display | Comes with LCD display liquid level or space distance | ||

| Analog output | 4~20mA | ||

| Digital output | RS485, Modbus or Customized protocol (Optional) | ||

| Supply voltage | Standard DC24V(can do AC220V) lightning protection device built in | ||

| Ambient temperature | Normal temperature and pressure | ||

| Protection class | IP67 | ||

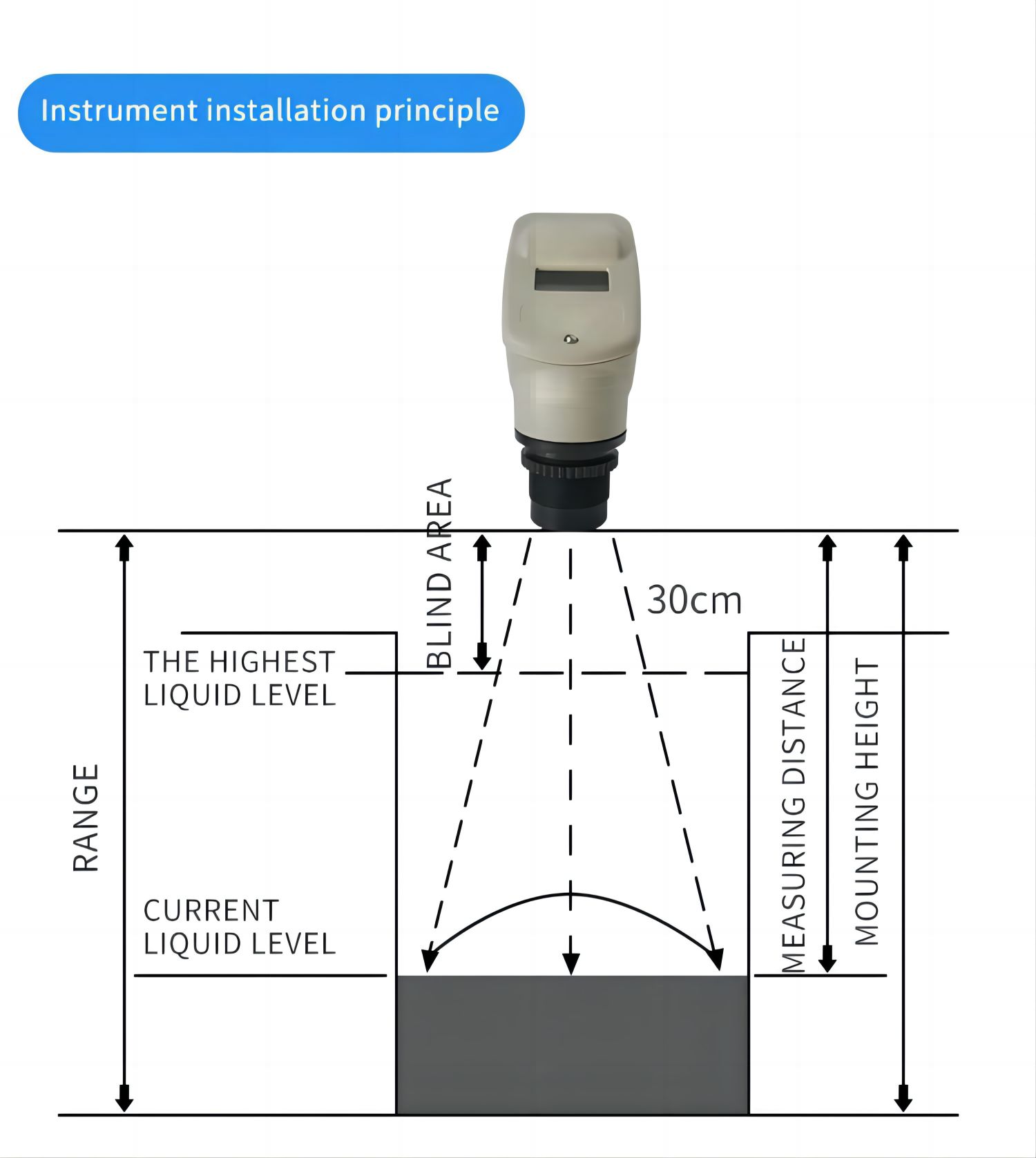

| Blind area | 0.3 m to 0.6 m | ||

| Ranging resolution |

1mm |

||

Product Display

Installation method:

In open environment, bracket installation is generally adoptedand fixed with the flange of the instrument. Cut a 60MM diameter roundhole in the mounting position of the tank or tank, put the meter probe inand tighten the flange from top to bottom.The installation must ensurethat the probe surface of the instrument is level with the measured liquidlevel, and the probe should be about 30 cm away from the page.

1.The distance from the transmitter surface of the probe to the lowest liquid level should be less than the range of the optional instrument

2.The distance between the probe transmitting surface and the highest liquid level shall be greater than the blind area of the optional instrument

3.The transmitting surface of the probe should be parallel to the liquid surface

4.The installation position of the probe should be as far as possible to avoid directly below the inlet, outlet and other liquid level dramatic fluctuations

5.If the wall of the pool or tank is not smooth, install the meter at least 0.5m away from the wall of the pool or tank

6.If the distance between the probe launching surface and the highest liquid level is less than the blind area of the optional instrument, it is necessary to install an extension tube. The diameter of the extension tube is greater than 120mm, and the length of the extension tube is 0.35m~0.50m.Vertically installed, the inner wall is smooth, and the hole on the tank should be larger than the inner diameter of the extension tube.Or pass the pipe to the bottom of the tank. The diameter of the pipe is greater than 100mm. Leave a hole at the bottom of the pipe to keep the liquid level in the extended pipe equal to that in the tank

FAQ

Can you produce according to the samples or drawings?

Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

What is the lead time?

For standard models, lead time is about 3~5 days after order confirmed and payment received.

For OEM orders, the delivery is about 2~3 weeks after data confirmed and payment received.

How to solve the quality problems after sales?

Take photos or videos of the problems and send to us.

We will make a satisfied solution for you within 24 hours after we confirm the problems.

X

X