YK-013-50 plastic drinking straw making machine is used to making plastic straws,as well as pipes,tubes,sticks,it's widely used in many different indudstries.

The 01 series three color plastic extrusion production line are used to produce plastic drinking straws,plastic tube,coffee sticks, cotton swab sticks and other plastic pipe or tubes.

It has models such as multi-color co-extrusion, three-color co-extrusion, two-color co-extrusion, and single-color extrusion lines.

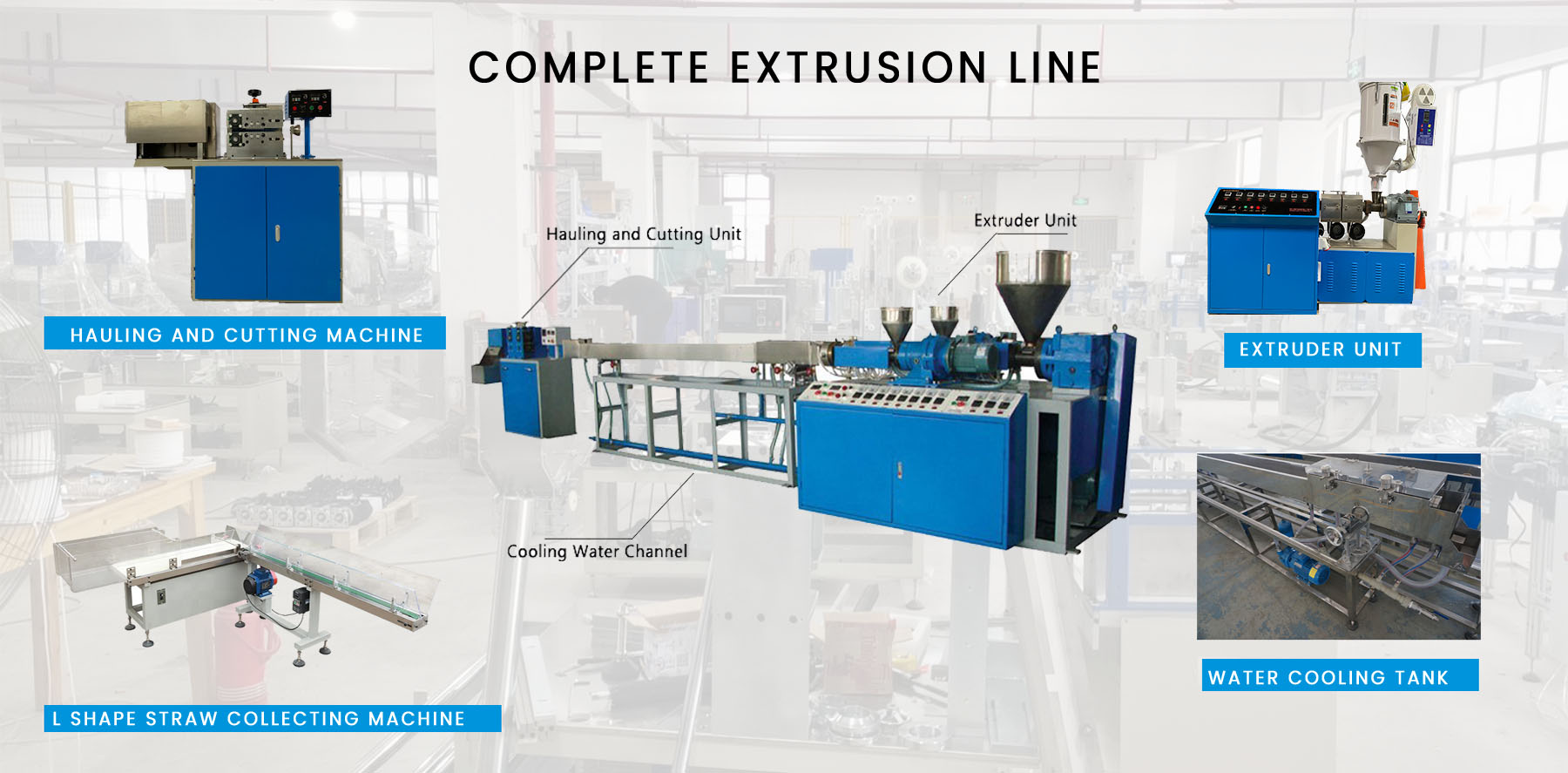

The whole system consists of three main parts: Main extruder unit, cooling water tank, hauling and cutting machine.

|

Features

Machine details

|

Extruder unit Main screw diameter:50mm Sub screw diameter:25mm Three color (one color,two color optional) Delta frequency converter Wanan motor Automatically feeding device(optional) |

|

Cooling water tank Standard length:3.5meter (for main screw diameter 50mm) Stainless steel material Can be adjusted up & down,right & left,forward & backward,

|

|

|

Hauling & Cutting machine Easy to operate,controlled by converter; Diversified in cut ends,90°/90°,90°/45°,90°/60°,45° /45°,60°/60°; use with L shape straw collection device Hauling motor/cutting motor: 0.75kw *2 |

Specifications

| Model | YK-013-50 | |

| Color | Three color | |

| Stripes | Per customer request | |

| Description | 1.Main parts:main extruder unit,cooling water tank,hauling and cutting system 2.Main screw diameter:50mm, Sub-screw diameter: 25mm |

|

| Power supply | 380V 3P 50HZ (can be customized) | |

| Main screw ( diameter 50mm) | 7.5KW (VFD) | |

| Sub-screw ( diameter 25mm) | 0.75KW*2 | |

| Heating | 15KW | |

| Hauling motor | 0.75KW(VFD) | |

| Cutting motor | 0.75KW(VFD) | |

| Total power | 25.5KW | |

| Temperature controller | 11 SETS | |

| Electric control cabinet | 1 SET | |

| Automatic counting device | 1 SET | |

| Way of hauling | By rubber roller | |

| Way of cutting | Rotatory cutting | |

| Cooling water tank | standard 3.5meter,can be adjusted from up to down,right to left, forward to backward | |

| Specification of pipe | Raw material | PP/PE |

| Diameter | 2mm-13mm can be customized | |

| Length | customized | |

| Production speed | 20-30kg/hour (600~1000pcs/min) | |

| Cut end | 90°/90°,90°/45°,90°/60°,45° /45°,60°/60°;(optional) | |

| Machine dimension | 2.2*1*1.3m | |

| Whole line dimension | 9*1*1.7m | |

| Weight | 1000kg | |

Applications

The extrusion production line can be used to produce a lot of pipes, which can be used in food industry, also in other areas.

|

|

|

|

| Drinking straw | Coffee stir stick | Lollipop stick | Cotton swab stick |

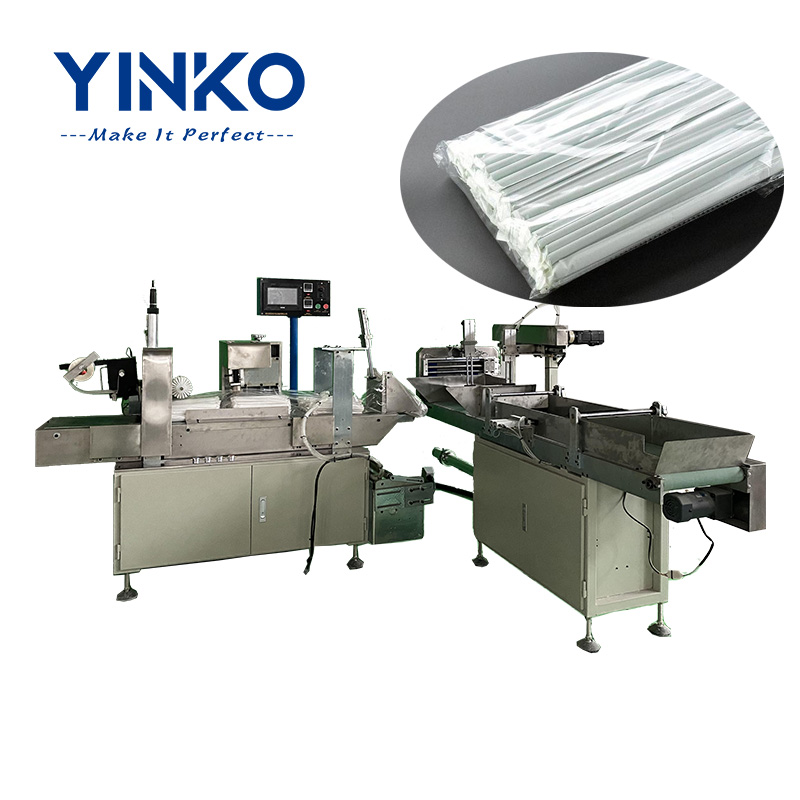

One stop solutions

We provide one stop solutions for drinking straw making, from straw extrusion machine to individual straw packing machine to multiple straw packing machine

|

|

|

| Plastic straw making machine | Individual straw packing machine | Multiple straw packing machine |

FAQ

|

1. What information shall i provide to get a quotation? Answer: you can tell us your requirements for the straw, like straw material, straw color, straw diameter, |

|

2. What shall i do if we want to produce different diameter straws/pipes? Answer: depend on your straw/pipe diameter,you need to change the mold |

|

3. Do you provide air compressor and water chiller? Answer: Yes, we can provide, you can also get in local market. |

|

4. Do you provide training/after sales service? Answer: Yes, training on site is better, we suggest customer can come and get training/testing here in our factory, for after sales,we normally provide spare parts with machines, for technical problem,we can arrange online meetings,or send engineer to your site. |

|

5. What about lead time and payment? Answer: Normally 35 days after deposit, we accept 30% deposit by TT, and balance before delivery. |

|

6. What other machines do you provide? Answer: We provide whole straw production line, from extrusion machine,flexible straw making machine to straw packing machine. one stop solutions |

X

X