The impact crusher adopts advanced crushing technology, which can meet the crushing of different material specifications and meet the requirements of the new process of "more crushing and less grinding". Not only the crushing ratio is large, but also the unit power consumption is low. The impact crusher can handle heavy materials with a side length of 100-500 mm or less, and its compressive strength can be up to 350 MPa. It has the advantages of a large crushing ratio, and the crushed mine materials are cubic particles. The equipment is small in size, simple in structure, large in crushing ratio, low in energy consumption, large in production capacity, uniform in particle size, and has selective crushing effect.

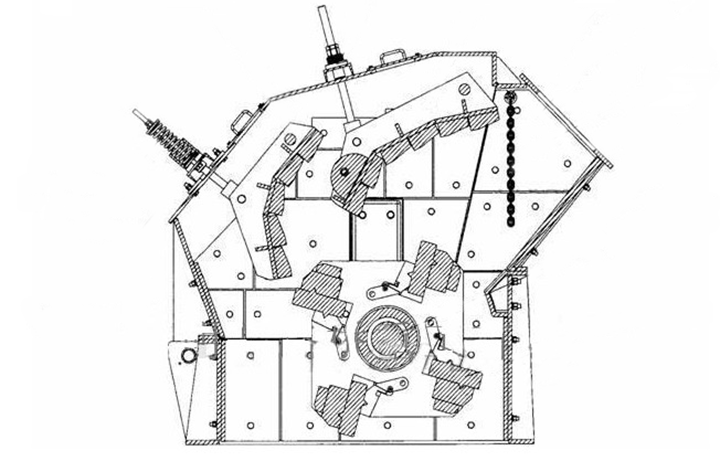

working principle:

Impact crusher is the machine which breaks materials using the impact energy. The rotor rotates of our impact crusher with a high speed driven by power motor when the machine is working. When the materials get into hammer effect area, they are impacting to break with the hammer on the rotor and then threw to the impacting position to take another crushing. After that they spring back to hammer impacting area from impact wrist plate to take crushing again. This procedure repeats itself. The materials get into 1, 2, 3 impact cavity from big to small to take repeated crushing. When the material is crushed to the required size, it's discharged from the outlet. The material's discharging size and shape can be changed through adjusting the gap between impact frame and rotator.

Specification

(mm)

Feeding Open

(mm)

Max.Feeding Length

(mm)

Capacity

(t/h)

Power

(kw)

Size(mm)

Weight

(t)

Model

PF-1010

1000×1050

400×1080

350

50-90

75

2530×1985×2196

11

PF-1210

1250×1050

400×1080

350

80-130

110

2638×2037×2713

14

PF-1214

1250×1400

400×1430

350

90-180

132

2580×2400×2810

19

PF-1315

1320×1500

860×1520

350

160-250

200

2840×2748×2556

24

PF-1320

1320×2000

860×2030

500

250-350

300

2900×3200×3250

30

X

X