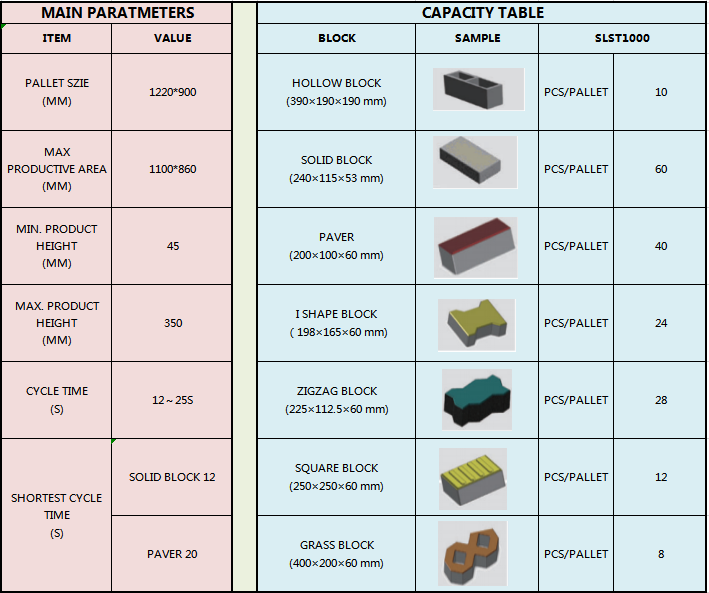

Adopting servo technology to adapt to all kinds of recycled aggregate from construction waste can greatly reduce the cost of brick making. Compared with ordinary brick machine, the production capacity is larger, the benefit is higher and the adaptability is wider. The special vibration and distribution system of this series of equipment can meet the needs of users for producing different products, such as color permeable pavement brick, standard brick, (bearing, common, split) block, grass planting brick, and concrete products such as curbstone, slope dike brick, chain brick, hydraulic block, etc.

The servo vibration system consists of a servo controller, four servo drives and four motors, the vibration table consists of vibration box and a vibration table. Before the pressing, the servo vibration system is turned on, and the vibration table vibrates at a lower frequency for the material feeding, after finish material feeding, the vibrating table vibrates at a higher frequency and presses the brick simultaneously.

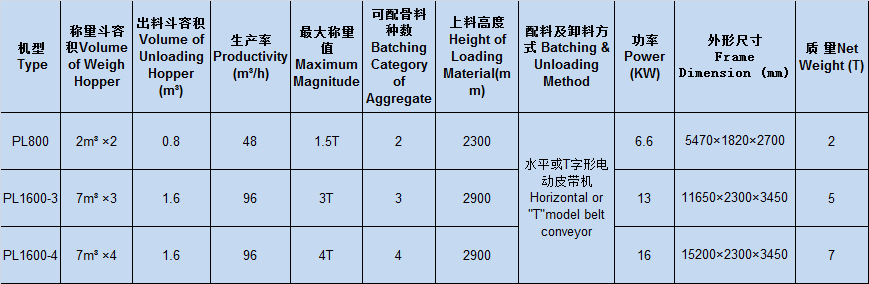

BATCHING MACHINE

MIXING SYSTEM

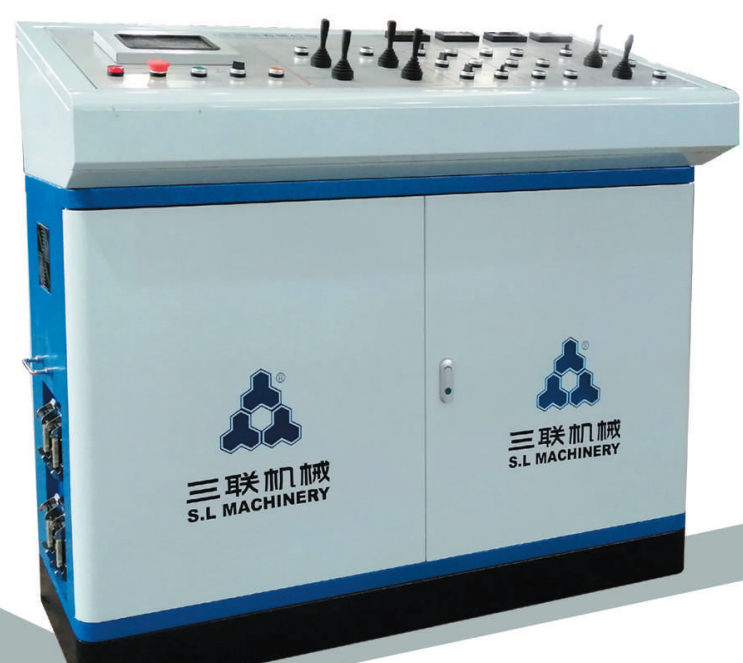

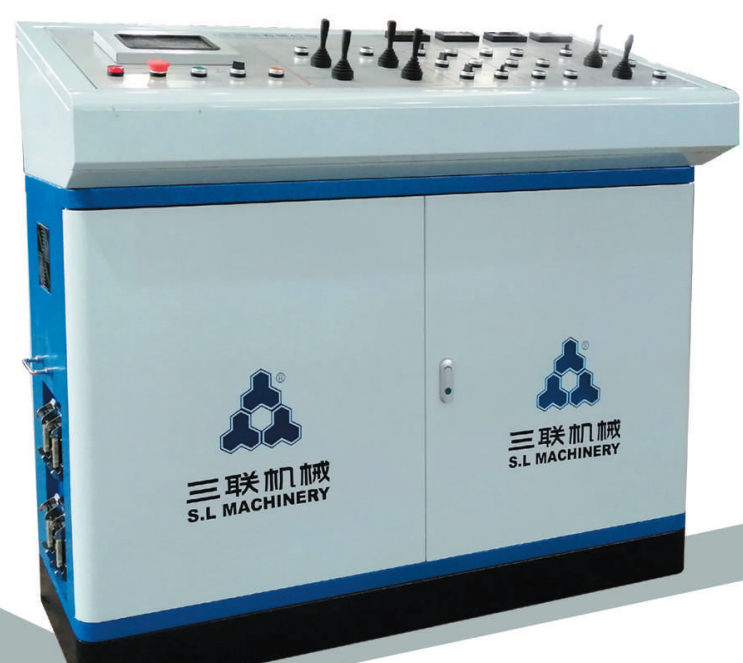

CONTROL SYSTEM

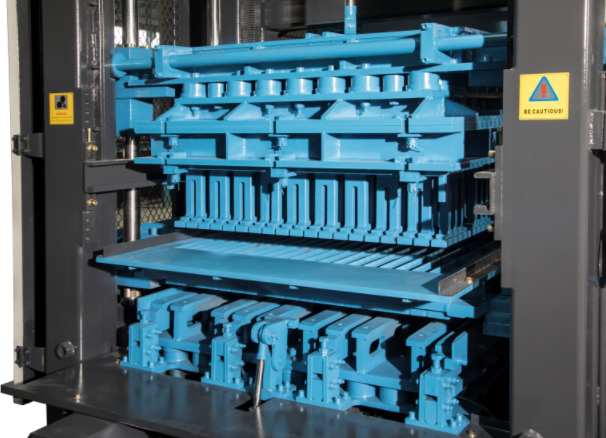

FORMING SYSTEM

X

X