Glass Emulsifying Mixer is mainly composed of emulsifier,vacuum system,lifting system,electrical control system,etc

The Lab Emulsifying Mixer is mainly used indaily chemical care products, biomedicine, food industry, coating ink, nano materials, petrochemical industry, printing and dyeing auxiliaries, paper industry, pesticide and chemical fertilizer, plastic rubber, power electronics, other fine chemicals, etc., especially for material emulsification configuration with high matrix viscosity and solid content.

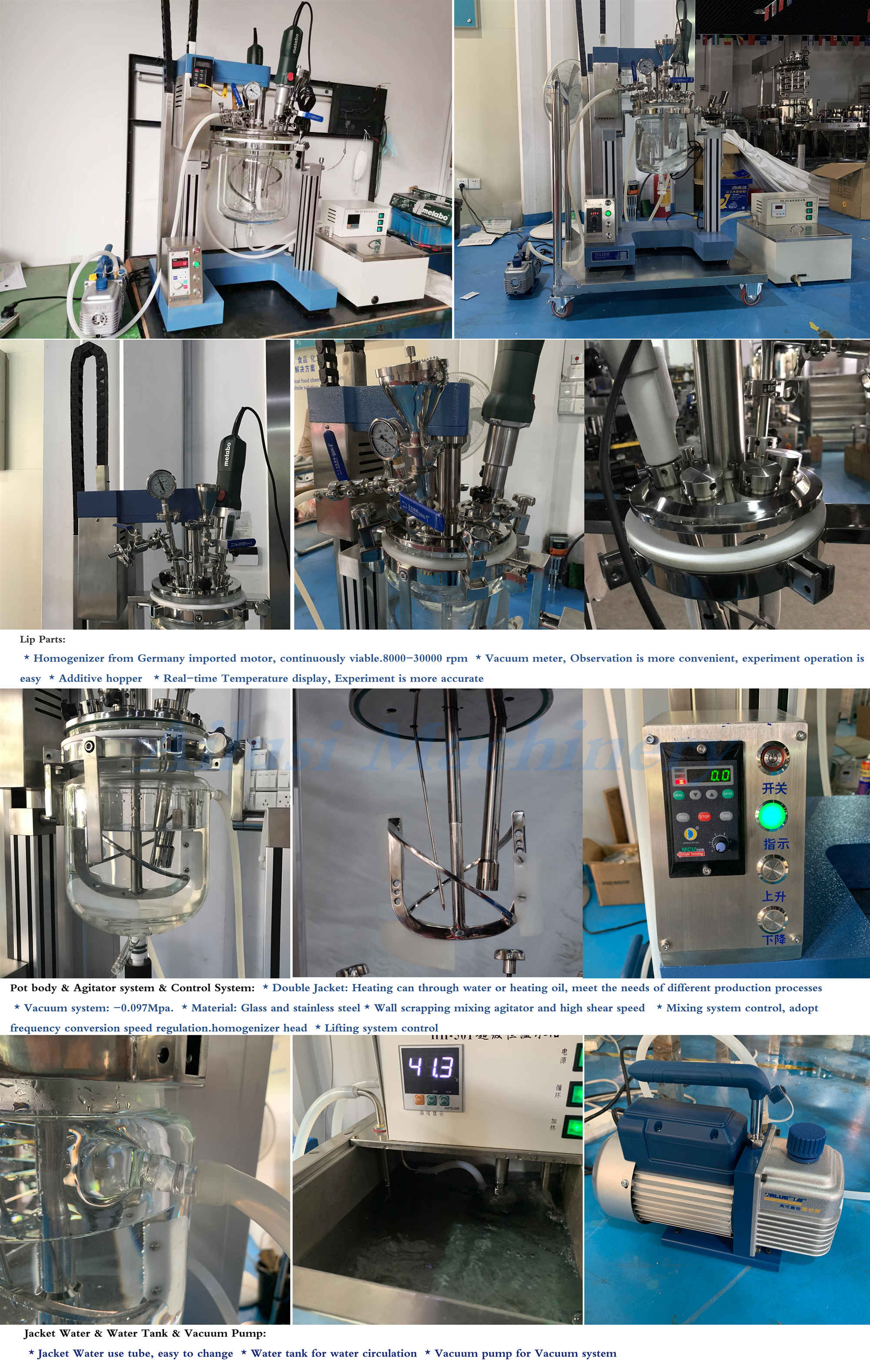

Main Feature:

1. Modular design, a variety of systems are available.

2. Laboratory Vacuum Emulsifier has Germany imported high-speed motor, long-life, stable operation.

3. The whole Glass Emulsifying Mixer structure of the design is reasonable, made of excellent materials

4. Stepless speed regulation, the maximum speed up to 30000rpm, the shear velocity can reach 27m / s.

5. Meet your different work environment (confined, open, atmospheric pressure, vacuum)

6. Overload protection and double protection insulation make sure for your security.

7. The cutting working head is made of stainless steel, which meets the GMP hygienic standard and can be used repeatedly.

For the capacity, we have 1L, 2L, 5L, 10L for your option.

* Simple structure

* Small volume

* Low noise

Package & Delivery:

To ensure the quality of our service, we will follow the standard package upon delivery:

1. All products before delivery should be tested by assembly and commissioning engineers. Our salesman need to send the tested video to the customer to ensure working well of the machines. Precision parts need to be packed in film or carton.

2. All products are packed in wooden boxes. Firmly fix the edge of the foot of the equipment to adapt the machine to the requirements of loading and uploading.

Our Servers:

Ailusi provide Turn-key Project Service to customer.

1. Factory Layout design;

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, Maintenance service.

X

X