Sesame seeds are a valuable crop, used in many food products and culinary dishes. However, their small size and dark color can make it difficult to separate high-quality seeds from defective or impure ones. That's where sesame seed color sorting machines come in. These machines use advanced imaging technology to sort sesame seeds based on their color and quality, resulting in a higher-quality product that is more desirable to buyers. In this article, we'll discuss how sesame seed color sorting machines work and the advantages they offer for sesame seed processing.

Sesame seeds are a valuable crop, used in many food products and culinary dishes. However, their small size and dark color can make it difficult to separate high-quality seeds from defective or impure ones. That's where sesame seed color sorting machines come in. These machines use advanced imaging technology to sort sesame seeds based on their color and quality, resulting in a higher-quality product that is more desirable to buyers. In this article, we'll discuss how sesame seed color sorting machines work and the advantages they offer for sesame seed processing.

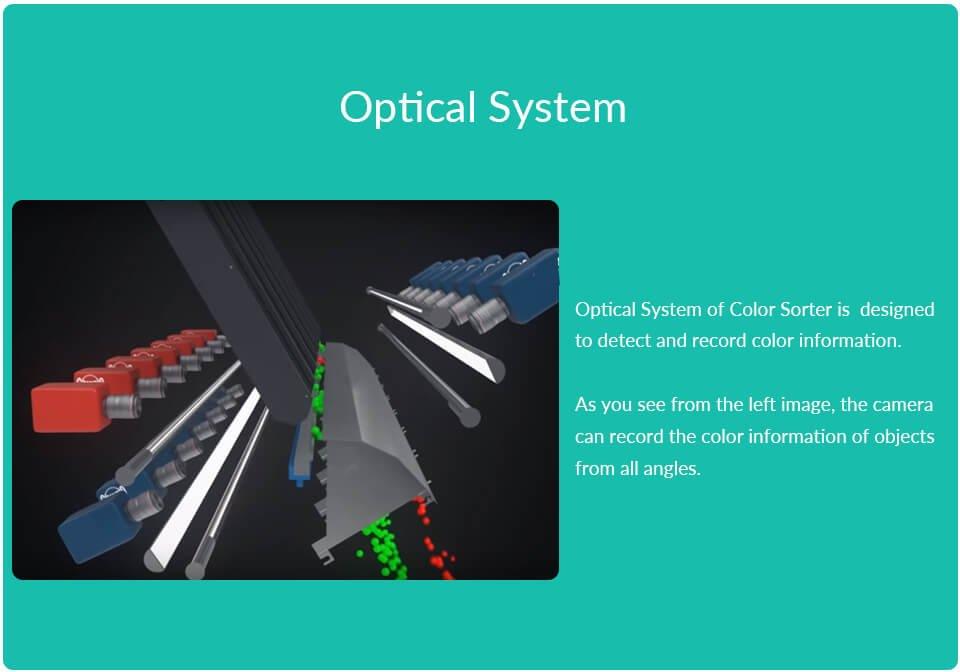

How Sesame Seed Color Sorting Machines Work: Sesame seed color sorting machines use high-speed cameras and advanced software algorithms to capture images of each individual seed as it passes through the sorting process. The software analyzes the images and identifies any defects or impurities, such as discolored or damaged seeds.

Once identified, the machine separates the defective seeds from the good ones using a series of air jets or mechanical arms. This results in a batch of high-quality, uniformly colored sesame seeds that are ready for further processing or packaging.

Advantages:

1.Increased Efficiency: Sorting sesame seeds by hand can be a time-consuming and labor-intensive process. Sesame seed color sorting machines can sort sesame seeds at a much faster rate, resulting in a more efficient sorting process and faster turnaround times.

2.Improved Quality: Sesame seed color sorting machines can identify and remove defective or impure seeds, resulting in a higher quality batch of sesame seeds that are more desirable to buyers.

3.Cost Savings: By automating the sorting process, sesame seed color sorting machines can reduce labor costs and improve the overall profitability of a processing operation.

4.Customizable Options: Sesame seed color sorting machines can be customized to meet the specific needs of a processing operation, ensuring that they get the most out of their investment.

5.How Sesame Seed Color Sorting Machines Help Sesame Seed Processing: Investing in a sesame seed color sorting machine can help sesame seed processing operations increase their profits in several ways. First, by improving the quality of their sesame seeds, processing operations can command a higher price from buyers. Second, sesame seed color sorting machines can reduce the amount of waste and rejected seeds, resulting in a higher yield and increased profits. Finally, sesame seed color sorting machines can increase the efficiency of the sorting process, resulting in faster turnaround times and increased production capacity.

Conclusion: If you're in the sesame seed processing industry and looking to improve your efficiency and profitability, investing in a sesame seed color sorting machine is a smart choice. With its advanced imaging technology and efficient sorting process, a sesame seed color sorting machine can improve the quality of your sesame seeds, reduce waste, and increase your production capacity, resulting in higher profits for your business. Contact us today to learn more about how a sesame seed color sorting machine can benefit your sesame seed processing operation.

Model |

MSRC-1 |

MSRC-2 |

MSRC-3 |

MSRC-4 |

MSRC-5 |

MSRC-6 |

MSRC-7 |

MSRC-8 |

MSRC-10 |

MSRC-12 |

|

Channels |

64 |

128 |

192 |

256 |

320 |

384 |

448 |

512 |

640 |

768 |

|

Capacity(t/h) |

1.0-2.0 |

1.0-4.0 |

2.0-6.0 |

3.0-8.0 |

5.0-10 |

7.0-12.0 |

9.0-17.0 |

11.0-20.0 |

14-28 |

17-35 |

|

Power(kw) |

0.8 |

1.4 |

1.8 |

2.2 |

2.6 |

3 |

3.5 |

4 |

5 |

6 |

|

Voltage(V) |

110-250V/ |

110-250V/ |

110-250V/ |

110-250V/ |

110-250V/ |

110-250V/ |

110-250V/ |

110-250V/ |

110-250V/ |

110-250V/ |

|

Sorting accuracy |

99.99% |

99.99% |

99.99% |

99.99% |

99.99% |

99.99% |

99.99% |

99.99% |

99.99% |

99.99% |

|

Rejection rate(bad:good) |

≧15:1 |

≧15:1 |

≧15:1 |

≧15:1 |

≧15:1 |

≧15:1 |

≧15:1 |

≧15:1 |

≧15:1 |

≧15:1 |

|

Dimension(mm) |

960*1630* |

1340*1630* |

1610*1630* |

1965*1630* |

2225*1290* |

2595*1630* |

2980*1630* |

3350*1630* |

2116*2967* |

2595*2967* |

|

Air consumption |

400-800 |

600-1000 |

800-1600 |

1000-1800 |

1300-2200 |

1500-3000 |

1800-3600 |

2000-4000 |

2700-5000 |

2000-4000 |

|

Weight(kg) |

210 |

350 |

600 |

750 |

880 |

1050 |

1150 |

1400 |

1400 |

1400 |

From optical sorting to color vision sorting,and then to multidimensional fusion sorting. From computational intelligence to perceptual intelligence, and then to the iteration of cognitive intelligence, every technological revolution of HT is changing the world we are familiar with.

HT has grown for more than 20 years, and has gone deep into the processing industries such as beans, seeds,nuts, wheat and grains, focusing on advanced technical research on material sorting. HT' S new series of deep learning equipment brings multiple value experiences to customers for multi scenario applications.

New intelligent algorithm & communication architecture,AI deep self-learning

Hardware platform architecture,standardization, modularization,high stability and low failure rate

The effect is not trivial,output increased by 15%,the accuracy is increased by 10%,bring out ratio reduced by 20% .

Pure and extraordinary sorting performance

Expandable design can be equipped with multi-dimensional cameras.

Network cloud platform

Realize real-time data monitoring

1,Near human eye vision color sorting technology, using 16 million colors, brings the best sorting performances

2,Full-color cameras optical system, with dimensional control of the defects, allows 0.1mm optical resolution

3,Image acquisition allows the easy and accurate setting of the defects to remove. Software adjustment is completely automatic thanks to HSV technology

4,Shape-sizing integrated into the system

5,Most concentrated rejects, thanks to customized hi-tech ejectors

6,Highest production capacities, automatically regulated by a feeder control device

7,Possibility to have simultaneous product resort, even with reverse sorting and third sorting.

8,Possibility to add sloping chutes for sorter upgrading or production increase

9,Possibility to install additional cameras operating in NIR and InGaAs even after machine installation at working premises

10,Led lighting system which is digital control

11,Automatic cleaning system, with adjustable frequency and duration

12,Tilting optical boxes, to allow an easy internal access for maintenance operations

13,Airtight optical boxes with controlled temperature

14,Designed mechanics grants the highest hygiene and prevents product outflow or accumulation

15,Provision with de-dusting suction systems

16,14-inches display with full-color and multilingual touch-screen

17,Flexible and user-friendly

18,Reduced electric and compressed air consumption.

19,CE,CSA certification

20,Use best quality components to ensure excellent quality.

21,From one chute to sixteen chutes to meet any different production capacity requirement

Packaging & Shipping

Machines to be carefully packaged to endure transportation under harsh conditions. Handling instructions are designed to protect the machine in the critical moments during transportation, unloading and installation.

Delivery Time: 10- 20 Days after order confirmed.

Payment Terms: TT, Letter of Credit.

Commissioning and Installation

1. On Site Installation and Training Service by our professional engineer ;

2. Study and Learn the Machine Operation in Our Factory.

3. Responsive in 24 hours: Telephone, Email, Video or On Site Solutions by our Technical Experts.

More information about color sorter

Separate Materials By Color

Color sorters are intensively effective in sorting materials of different colors. Rice, grains, millets, and cereals are examples you might need to sort based on colors.

Separate Materials By Sizes

It is prevalent to sort foods by size. In general, a color sorter can sort products by sizes of 0.1mm to 100mm.

Separate Materials By Shapes

Sorting by shape is very useful to classify food like tea leaves and seafood. You can set the parameters you want and let the machine do the work.

Separate Materials By Types

In some cases, you might need to sort materials like nuts, seeds, and beans by type. To classify them efficiently and pick only the healthy ones.

Customer feedback is the driving force behind our progress:

Plywood Case is Suitable for Sea/Road/Air Transport:

1. How to use the machine?

We will supply the Installation instructions and videos for guiding you how to set color sorter.

2. How long about the guarantee period?

Two years. And we supply lifelong software upgrade services for our customers.

3. Can you supply the air compressor, air tank and air filters?

Yes, we can provide above equipments, our standard offer includes color sorter machine with air compressor & air tank & air dryer & air filters.

4. Is oversea service available?

Yes, we will send engineer go abroad when you need it.

5.How to calculate Installation personnel cost?

On condition that customer requires to install, our company would like to send 1 engineer to guide for installation, then customer should to pay the cost, including transaction of engineer’s visa, transportation(air) for go abroad. and accommodation , local transportation and security when the engineer arrived.

6. If you have agent in our country?

We have agent in UK,New Zealand,Italy,Crotia,India, Guatemala,Finland,Malaysia,Bangladesh,Pakistan,Nigeria,Ukraine,Nicaragua etc. and we can provide after-sales service in your Country.

We have many installation cases and working videos.Please contact us freely if you need.

X

X