♦14 hours battery (rechargeable), back-lit 4 lines display.

♦Data logger function.

♦Can be used for mobile measurement, flow rate calibration, data comparing, meters running status checking.

♦Non-invasive transducers.

♦Wide bi-directional flow range of 0.01 m/s to 12 m/s. Wide liquid temperature range: -35℃~200℃.

♦Works reliably in both clean and somewhat dirty liquids with turbidity<10000ppm.

♦Lightweight and easily transportable in box.

SCH-TF1100-CH Handheld Transit-Time Ultrasonic Flowmeter

The Ultrasonic Flow Meter works on the transit-time method. The clamp-on ultrasonic transducers (sensors) are mounted on the external surface of the pipe for non-invasive and non-intrusive flow measurement of liquid and liquefied gasses in fully filled pipe. Three pairs of transducers are sufficient to cover the most common pipe diameter ranges.

User can use hand to hold as well as to operate the flow meter main unit. This flexible and easy to use flow meter is the ideal tool for the support of service and maintenance activities. It can also be used for the control or even for the temporary replacement of permanently installed meters.

Specifications: Transmitter

| Measurement principle | Ultrasonic transit-time difference correlation principle |

| Flow velocity range | 0.01 to 12 m/s, bi-directional |

| Resolution | 0.25mm/s |

| Repeatability | 0.2% of reading |

| Accuracy | ±1.0% of reading at rates >0.3 m/s);±0.003 m/s of reading at rates<0.3 m/s |

| Resonse time | 0.5s |

| Sensitivity | 0.003m/s |

| Damping of displayed value | 0-99s(selectable by user) |

| Liquid Types Supported | both clean and somewhat dirty liquids with turbidity <10000 ppm |

| Power Supply | AC: 85-265V Up to 14 h with fully charged internal batteries |

| Enclosure type | Handheld |

| Degree of protection | IP65 according to EN60529 |

| Operating temperature | -20℃ to +60℃ |

| Housing material | ABS( UL 94HB) |

| Display | 4 line×16 English letters LCD graphic display, backlit |

| Units | User Configured (English and Metric) |

| Rate | Rate and Velocity Display |

| Totalized | gallons, ft³, barrels, lbs, liters, m³,kg |

| Communication | OCT, Relay, RS232, RS485 (Modbus),Logged data |

| Security | Keypad lockout, system lockout |

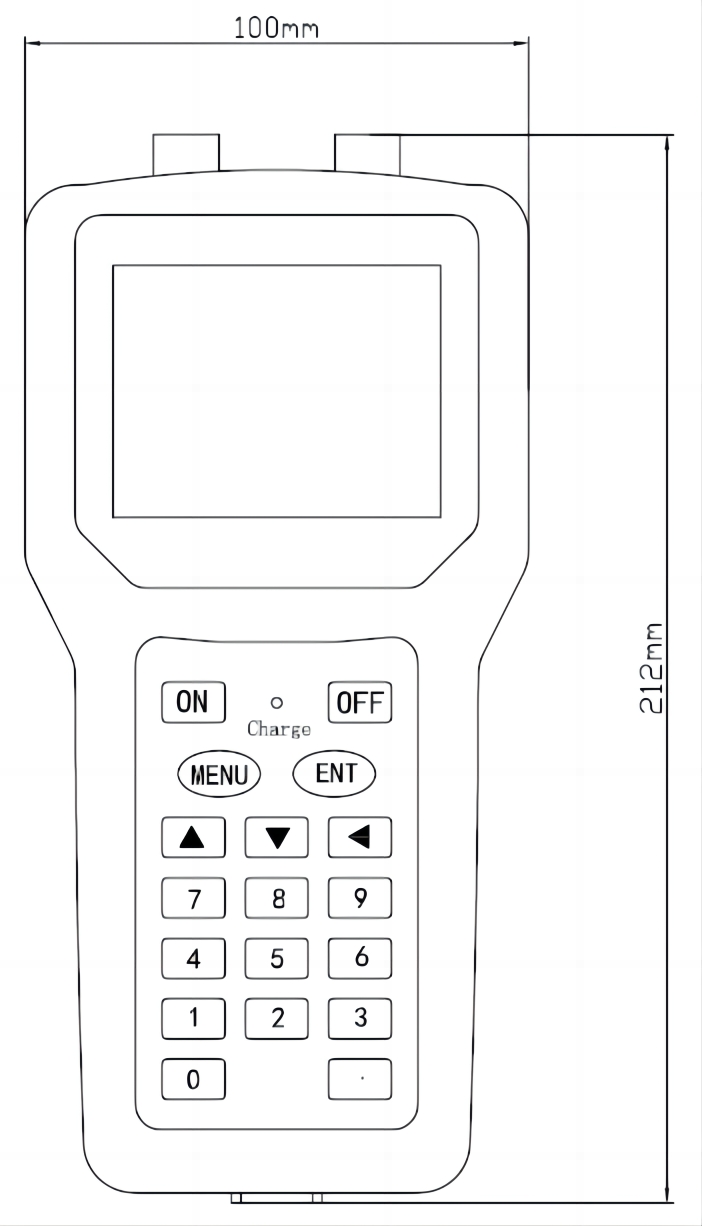

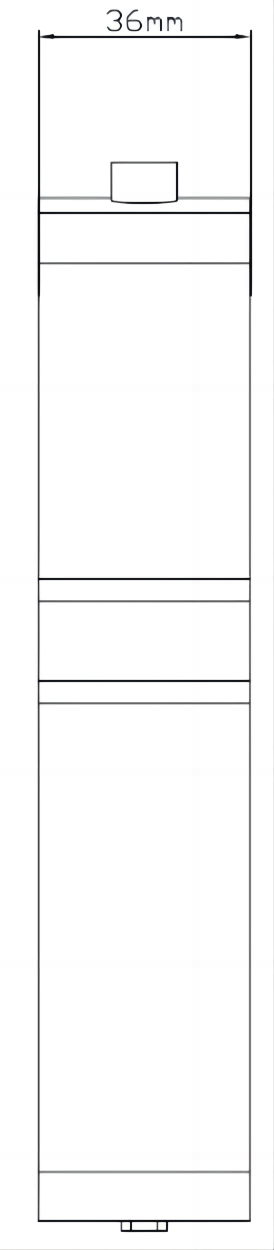

| Size | 212*100*36mm |

| Weight | 0.5kg |

Specifications: Transducer

| Degree of protection | IP65 according to EN60529.(IP67 or IP68 Upon request) |

| Suited Liquid Temperature | Std. Temp.: -35℃~85℃ for short periods up to 120℃ |

| High Temp.: -35℃~200℃ for short periods up to 250℃ | |

| Pipe diameter range | 20-50mm for type S, 40-1000mm for type M, 1000-6000mm for type L |

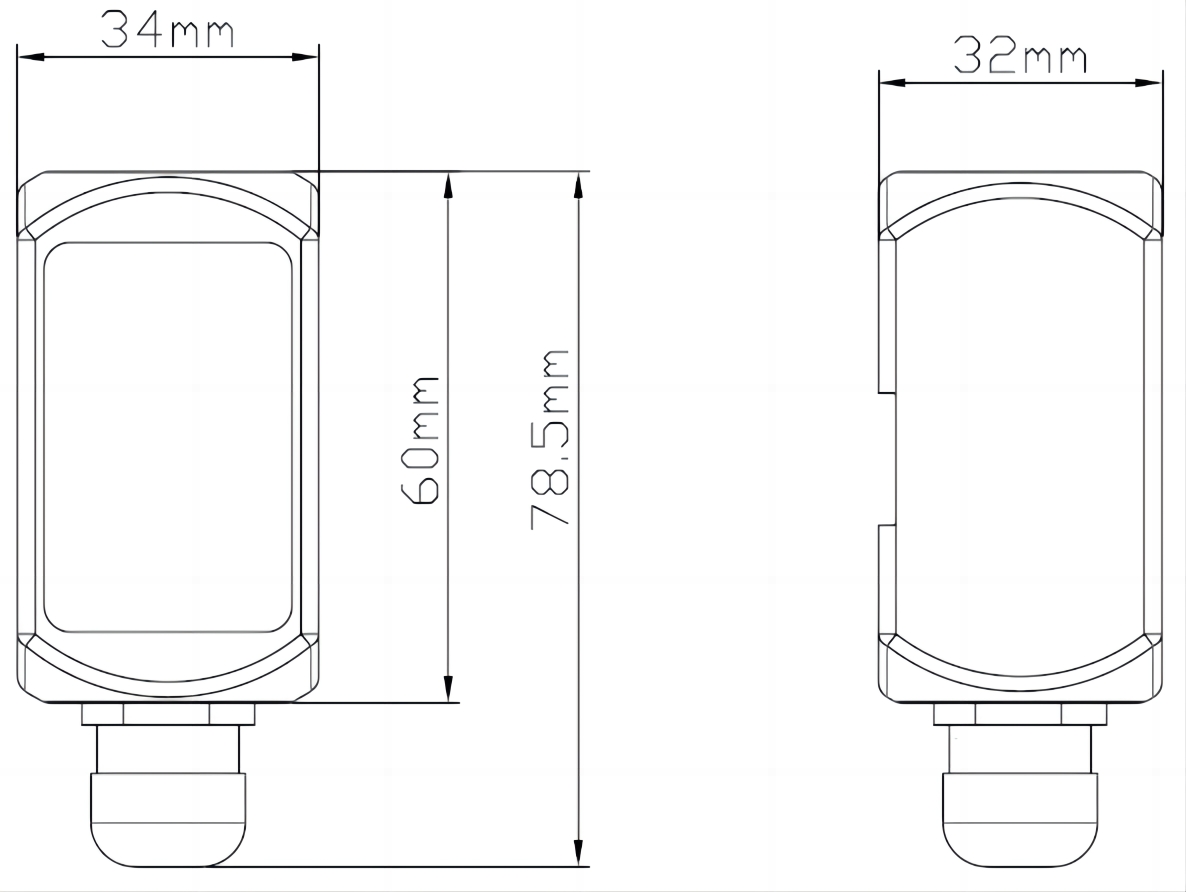

| Transducer Size | Type S 52(h)*28(w)*26(d)mm |

| Type M 60(h)*34(w)*33(d)mm | |

| Type L 80(h)*40(w)*42(d)mm | |

| Material of transducer | Aluminum for standard temp. sensor, and peek for high temp. sensor |

| Cable Length | Std: 5m |

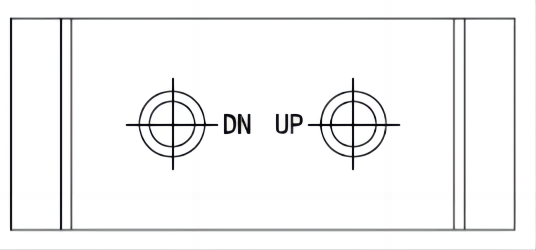

Dimensional Sketches

FAQ

Can you produce according to the samples or drawings?

Yes, we can produce by your samples or technical drawings. We can build the molds

What is the lead time?

For standard models, lead time is about 3~5 days after order confirmed and payment received.

For OEM orders, the delivery is about 2~3 weeks after data confirmed and payment received.

How to solve the quality problems after sales?

Take photos or videos of the problems and send to us.

We will make a satisfied solution for you within 24 hours after we confirm the problems.

X

X