♦Pulse mode: monopulse/double-pulse/orthogonal pulse

♦Signal level: 3.3~24V compatible; series resistance not necessary for the application of PLC

♦Power voltage: 24~100V DC or 18~80V AC; 48V or 60V AC recommended

SCH-R130 two-phase stepper driver

The R130 digital 2-phase Stepper drive is based on TI's 32-bit DSP platform and integrated with the micro-stepping technology and the auto tuning of power-up parameters. With the features of low noise, low vibration, low heating and high-speed high torque output, it is suitable for most stepper motors.

Typical application: carving machine, cutting machine, screen printing device, numerical control machine, automatic assembly equipment

Product Specification

| Pulse mode | Single/double pulse | ||

| Signal level | 3.3~24V compatible,no series resistance required for PLC applications | ||

| Power supply voltage | 110-230V AC | ||

| Typical Application | Engraving machines, cutting machines, silk screen equipment, CNC machine tools, automatic assembly equipment, etc | ||

| Operating voltage range | 110VAC-230VAC | ||

| Operating current range | 1.3~7.0A | ||

| Matching motor | 86 series, 110 series, and 130 series or lower motors | ||

| Rich control signal interface | PUL&DIR,CW+CCW | ||

| Control signal interface level | 3.3V-24VDC | ||

| The entire series provides 8 levels of current and 16 levels of subdivision settings. | |||

| Adaptive parameter identification enables the motor to have high-quality noise and performance under various voltage conditions | |||

| High reliability, providing overvoltage, overcurrent and other protection functions. | |||

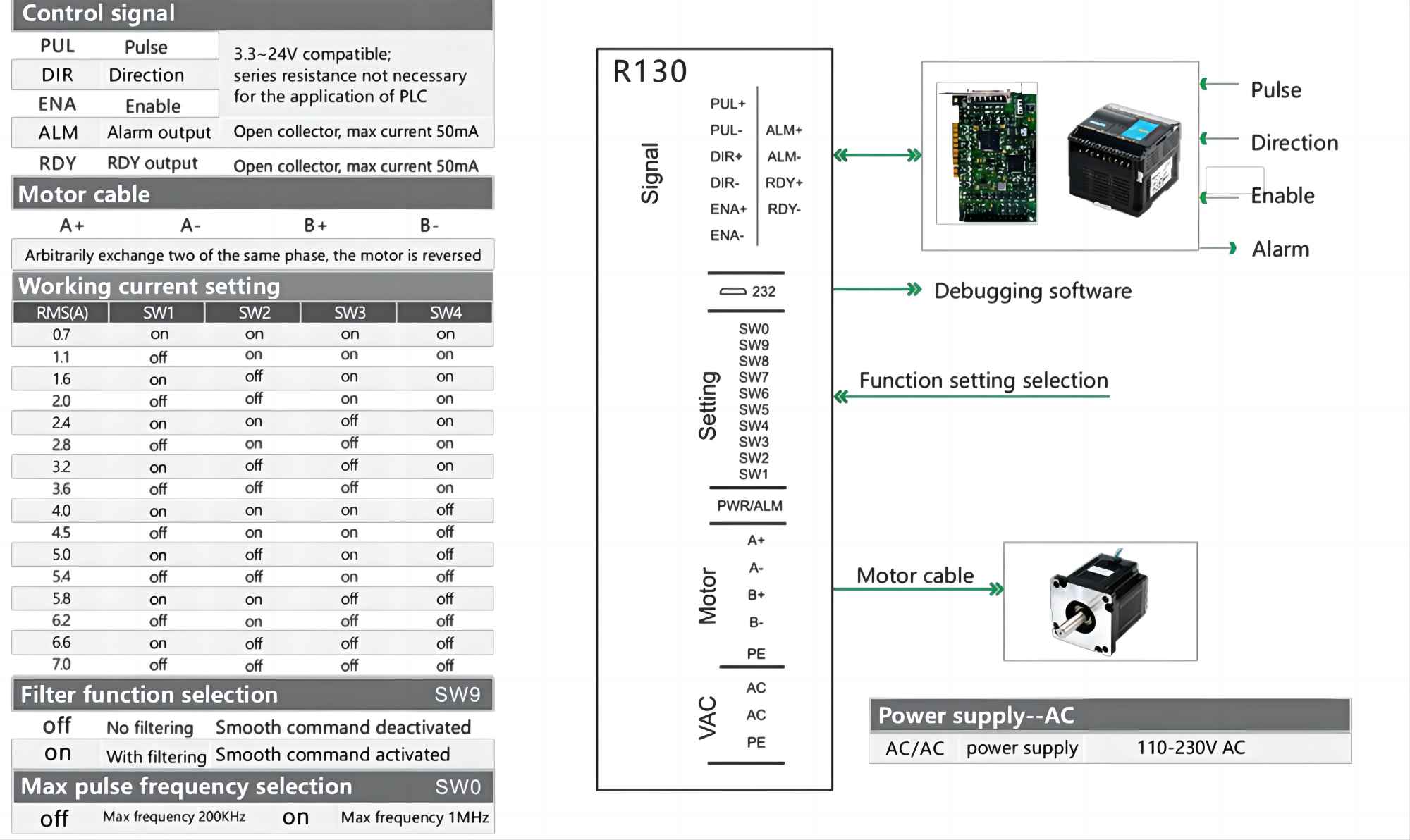

Driver function

| Driver function | Operating instructions |

| Microstep fine score setting | SW5-SW8 Four dip switches are used to select a total of 16 micro step subdivisions. Please select the correspondingsubdivision by referring to the driver panel, and ensure that the drive is not active when setting. |

| Output current setting | SW1-SW4 Three dip switches are used to select a total of 16 output currents. Please select the corresponding subdivision against the driver panel, and ensure that the driver is not active when setting. |

| Automatic half-current function | SW9 Dip switches are used to ssmoothing function of the drive. off means to turn this feature offand on means to turn it on. SWO is used to select the bandwidth of the drive, the maximum pass pulse frequenc!is 200KHZ when off, and the maximum pass pulse frequency is lMHZ when on. |

| Signal interface | PUL+ and PUL- for the positive and negative ends of the control pulse signal, DlR+ and DlR- for thepositive and negative end of the direction signal; ENA+ and ENA - for the positive and negative ends ofthe enable signal., AlM+ and ALM- for the positive and negative ends of the alarm signal and RDy+ andRDY- for the positive and negative ends of the place signal. |

| Motor interface | A+ and A- are connected to the positive and negative ends ofthe A-phase winding ofthe stepper motor; B+ and B- are connecterto the positive and negative ends ofthe B phase windings of the stepper motor. when the A and B phase windings are switchedthe direction of the motor can be reversed |

| Power interface | The Rl30 working voltage range is reconmmended for AC 110-230V, it is recommended to add an EMl FlLTER before the power supply circuit. |

| ndicators | The drive has two indicator lights, red and green. The green light is the power indicator, and the green lightblinks when the driver is powered on: The red light is the fault indicator, when there is overyoltage.overcurrent fault, the fault light blinks. After the fault is cleared, the red light turns off. When the drive fails, thefault can only be cleared by re-powering and re-enabling it. |

SCH-R130 Connections

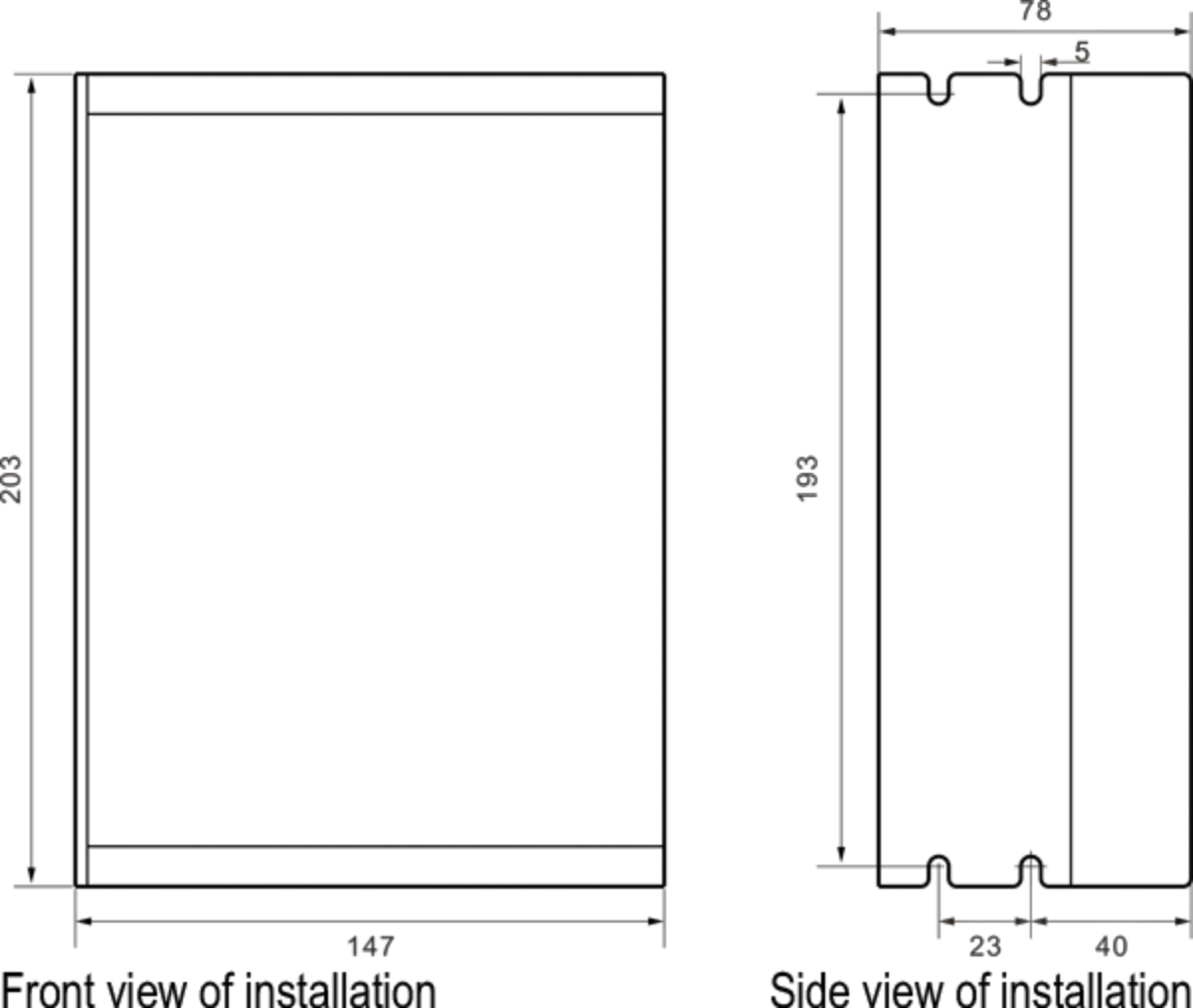

Product Dimensions

FAQ

Can we accept samples customized?

No problem for samples order, and welcome your testing before your big order.

OEM and ODM are available?

Yes, we accept customized products

Can I get a lower price if I order large quantities?

Yes, Cheaper prices with bigger size orders, please contact us and we will give you a quatation.

X

X