♦Meet the needs of different process-es, adjust the motor speed in onebuilding,save commission time.

♦Automatically detecting the load cur-rent and adjusting the output voltage.exerts a good energy-saving effect.re-duce the energy cost.

♦High torque control in low frequency0.5Hz/150%SVC), and 0Hz/200%(FVC)real vector control with three hall sensorcurrent detecting,output frequency up to3200hz,support PID control.

♦Complete motor protection for exam-ple,over-voltage stall, under-voltage,current limit, overload, overheat, overspeed, overvoltage,etc......

SCH-MAX500 series frequency inverter

SCH-MAX500 series frequency inverters with direct torque control technology and motor flux optimization func-tions as well as energy saving functions can slove the problem of harmonics ,noise andenergy saving ,higher precision as well as efficiency and protection.Widely applicationfor the filed of Steels, Cement, Chemical, Oil & Gas, Power, Polymer & Rubber, Pulp &Paper, Sugar, Minerals & Mining..

Technical Specification

| Item | Specifications | ||

| Standard functions |

Maximum frequency | 0~3200.00Hz | |

| Carrier frequency | 0.5-16 KHz(The carrier frequency is automatically adjustec based on the load features.) | ||

| Input frequency resolution | Digital setting:0.01 Hz Analog setting:maximum frequency x 0.025% |

||

| Control mode | Sensor-less flux vector control (SFVC) Closed-loop vector control (CLVC)(+PG Card) Voltage/Frequency(V/F)control |

||

| Startup torque | G type:0.3Hz/150%(SFVC);0 Hz/180%(CLVC) P type:0.5Hz/100% |

||

| Speed range | 1:200(SFVC) | 1:1000(CLVC) | |

| Speed stability accuracy | ±0.5%(SFVC | ±0.02%(CLVC | |

| Torque control accuracy | ±5%(CLVC) | ||

| Overload capacity |

G type:60s for 150%of the rated current,3s for 180%of the rated current P type:60s for 120%of the rated current,3s for 150%of the rated current |

||

| Torque boost | Auto boost; Manual boost:0.1%~30.0% |

||

| V/F curve | Straight-line V/F curve Multi-point V/F curve N-powerV/F curve (1.2-power, 1.4-power, 1.6-power, 1.8-power,square |

||

| V/F separation | Two types:complete separation;half separation | ||

| Acceleration/dec eleration curve |

Straight-line ramr S-curve ramp Four groups of acceleration/deceleration time with the range of 0.00s~65000s |

||

| Standard functions |

DC braking | DC braking frequency:0.00 Hz~maximum frequency Braking time:0.0~100.0s Braking trigger current value:0.0%~100.0% |

|

| JOG control | JOG frequency range:0.00Hz~50.00 Hz JOG acceleration/deceleration time:0.00s~65000s |

||

| Built-in PLC,multiple speeds | It realizes up to 16 speeds via the simple PLC function or combination of Dl terminal states. |

||

| Built-in PID | lt realizes closed loop control system easily. | ||

| Auto voltage regulation (AVR | It can keep constant output voltage automatically when the mains voltage fluctuation. |

||

| Overvoltage/ Over current stall control |

The current and voltage are limited automatically during the running process so as to avoid frequently tripping due to overvoltage/over current |

||

| Rapid current limit function | It can auto limit running current of frequency inverter to avoid frequently tripping |

||

| Torque limit and control | (Excavator characteristics)It can limit the torque automatically and prevent frequently over current tripping during the running process. Torque control can be implemented in the VC mode. |

||

| Individualize d functions |

High performance | Control of asynchronous motor is implemented through the high-performance current vector control technology |

|

| Instant power not stop | The load feedback energy compensates the voltage reduction so that the frequency inverter can continue to run for a short time. |

||

| Rapid current limit | To avoid frequently over current faults of the frequency inverter | ||

| Timing control | Time range:0.0~6500.0 minutes | ||

| Multiple communication protocols |

Currently supports communication bus via Modbus-RTU and later will support PROFIBUS-DP,CANopen,etc |

||

| Motor overheat protection | The optional I/O extension card enables Al3 to receive the motor temperature sensor input(PT100,PT1000)so as to realize motor overheat protection. |

||

| Multiple encoder types | lt supports incremental encoder and encoder such as differential encoder,open-collector encoder resolver,UVW encoder,and SIN/COS encoder. |

||

| Advanced background software | It supports the operation of frequency inverter parameters and virtualoscillograph function,by which the state of frequency inverter can be monitored. |

||

| Run | Running command giving | key panel Control terminals Serial communication port You can switch between these giving in various ways. |

|

| Frequency giving | There are 10 kinds frequency giving:digital setting,analog voltage setting,analog current setting,pulse setting,serial communication port setting,panel potentiometer,etc. You can switch between these giving in various ways |

||

| Auxiliary frequency giving | There are 10 kinds auxiliary frequency giving.It can implement tiny tuning of auxiliary frequency and frequency synthesis. |

||

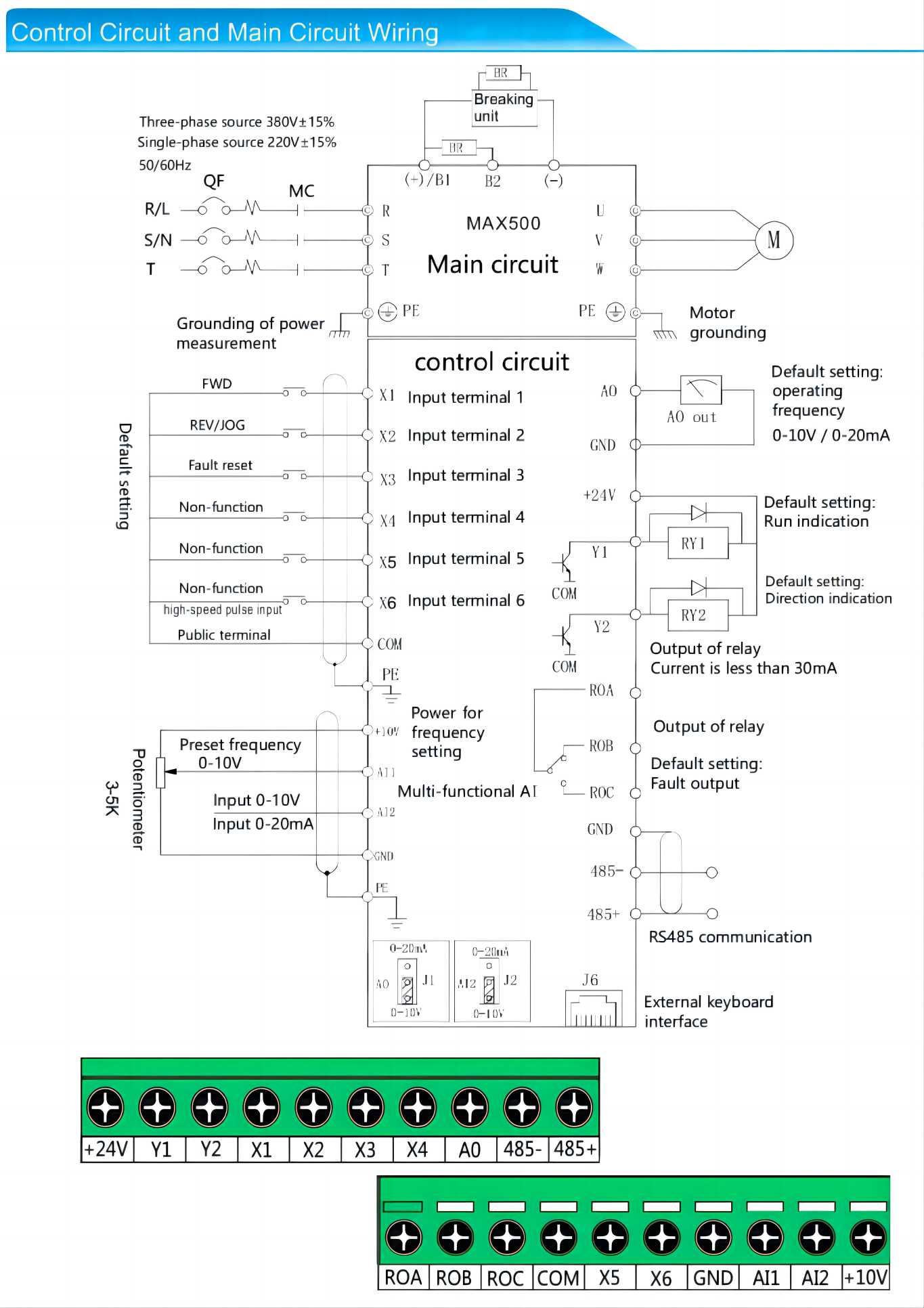

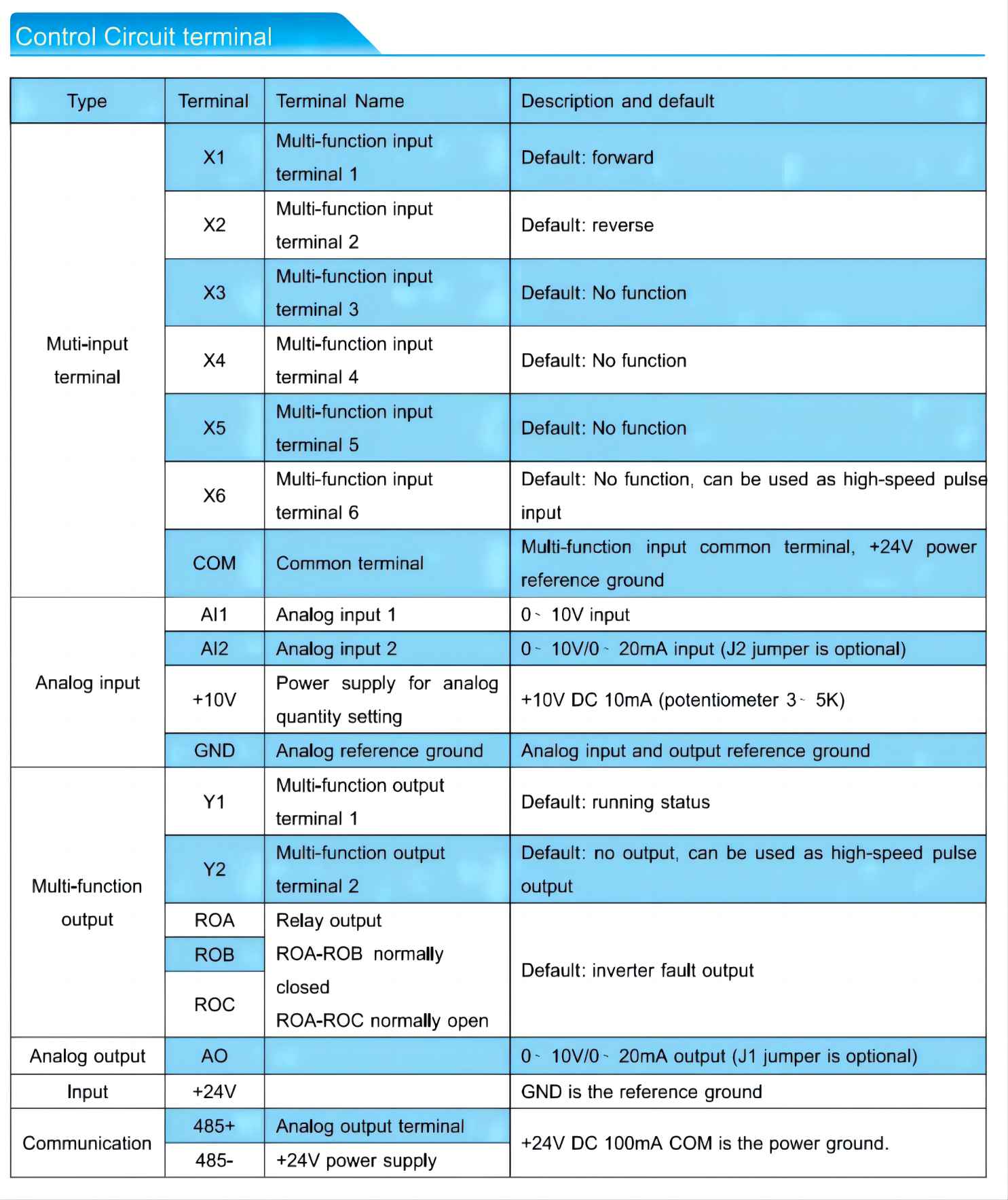

| Input terminal | Standard: 6 digital input (Dl)terminals,one of which supports up to 100 kHz high-speed pulse input 2 analog input (Al)terminals,support OV~10 V voltage input or 0 mA~20 mA current input Expanding capacity 6 DI terminals 1 Al terminal supports -10V~10 V voltage input |

||

Technical instructions

FAQ

Can I get some samples?

Yes, Sample order is available for quality check and market test. But you have to pay the express cost.

What's delivery time?

It usually takes about 3-5 working days for small order and 10-15 days for big order.

How to solve the quality problems after sales?

Take photos or videos of the problems and send to us.

We will make a satisfied solution for you within 24 hours after we confirm the problems.

X

X