QUALITY Metal Ridge Cap Roll Forming Machine with GOOD AFTER-SALES SERVICE

Profile Drawing

Main Techinical Parameters

|

Technical Parameter |

Description |

|

Material Thickness |

0.3-0.6mm |

|

Material Width |

481mm |

|

Effective Width |

449mm |

|

Forming Station |

14 steps |

|

Motor power |

5.5Kw |

|

Weight |

6000KG |

Applicable Material: GI or PPGI with yield strength of 240-550MPA

Machine Components

1. One manual decoiler

Unpower, manual control still coil inner bore shrinkage and stop

2. Cold Rolling Mill

Body Frame made from H350 steel by welding;

Rollers manufactured from GCR15, CNC lathes;

Shafts manufactured from 45# steel, quenching and tempering treated

Motor driving, main motor=5.5KW

3. PLC Control Device

PLC control device can control the product quantity and product length automatically.

Operators input the date (production batch, pcs, length, etc) on the touch screen. It can finish the production automatically.

This PLC control device combined with PLC, Inverter, Touch Screen, Encoder, Closed-loop control, etc.

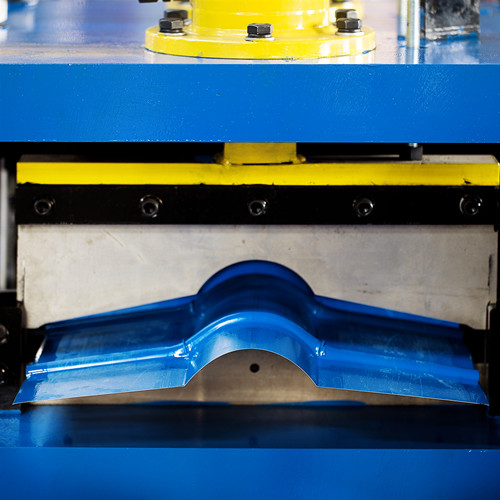

4. Hydraulic Cutting Device

One press mould+one cutting mould

Hydraulic power: 3.0KW

Cutting tool material: CR12, heat treatment

5. Finished Product

X

X