Simplified and shorter lead time rapid tooling to deliver low to mid-volume production parts for cost reduction and capability repeatability

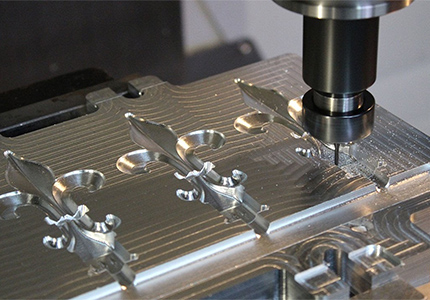

As product development cycles continue to shorten, rapid prototyping remains one of our most ideal services for low-volume production, concept testing, and pilot runs before mass investment. Premium Part offers reliable and affordable rapid tooling services to produce high-quality steel and aluminum prototype tooling. Our services cut across both low-volume, bridge, and mass production end-uses. We can integrate precision CNC machining through our digital manufacturing technology to make prototype and production mold that are durable, detailed, and long-lasting. At Premium Parts, we understand the need for perfection in all that we do—our design-for-manufacturability (DFM) analysis to help you improve design efficiency and reduce cost where possible. Our rapid tooling services are executed to capture even the tiniest detail in your mold and mold components. While we use hardened steel tooling for production runs that will involve high volumes, we can use aluminum tooling to make low-cost, quick, and dependable molds for rapid prototyping and low-volume production. We also offer mold making, multi-cavity tooling, and other specialized tooling services.

What is Rapid Tooling?

Rapid tooling is a rapid prototyping technique primarily used in place of conventional tooling to produce functional molds at lower costs and shorter lead times. This manufacturing method combines rapid prototyping techniques with the digital tenacity of electronic CAD data files to create a production mold instead of a part. The molds produced with rapid tooling services are often referred to as hard tooling. They are used in making hundreds to thousands copies of a part, serving as the "original" in plastic injection molding, and pressure die casting operations.

Rapid tooling holds several advantages over the conventional tooling process. Some of the key benefits of rapid tooling operations include:

1. Rapid Turnaround

Speed is the primary attribute of rapid tooling. Using the digital CAD file, and digital manufacturing, rapid tooling can make molds and dies for low to mid-volume production operations faster than conventional tooling. Rapid tooling operations can reduce around 40-60% of the traditional molding lead-times.

Speed is the primary attribute of rapid tooling. Using the digital CAD file, and digital manufacturing, rapid tooling can make molds and dies for low to mid-volume production operations faster than conventional tooling. Rapid tooling operations can reduce around 40-60% of the traditional molding lead-times.

Precision is imperative in tooling because your molds will be used to manufacture other copies. Rapid tooling uses digital technology that can fabricate tooling with high precision. This way, you can be rest assured on the accuracy and detail of rapid tooling, and confident in your tooling investment. Rapid tooling molds can be finished in various ways, including texturing, polishing, and bead blast blasting.

Precision is imperative in tooling because your molds will be used to manufacture other copies. Rapid tooling uses digital technology that can fabricate tooling with high precision. This way, you can be rest assured on the accuracy and detail of rapid tooling, and confident in your tooling investment. Rapid tooling molds can be finished in various ways, including texturing, polishing, and bead blast blasting. Rapid tooling allows you to innovate with freedom. With our digital capabilities integrated into our rapid tooling process, we can create mold tools with complex shapes and intricate patterns. Rapid tooling can also easily be modified to accommodate design changes and modifications.

Rapid tooling allows you to innovate with freedom. With our digital capabilities integrated into our rapid tooling process, we can create mold tools with complex shapes and intricate patterns. Rapid tooling can also easily be modified to accommodate design changes and modifications.  Rapid tooling can work around budgetary constraints and use aluminum tooling to manufacture low-cost molds for low to mid-volume production runs. Rapid tooling is around 40-50% cheaper than traditional mold tooling.

Rapid tooling can work around budgetary constraints and use aluminum tooling to manufacture low-cost molds for low to mid-volume production runs. Rapid tooling is around 40-50% cheaper than traditional mold tooling.

Rapid Tooling Applications

• Rapid prototyping & Low-volume production

Low-cost tooling through aluminum materials can help you make molds and dies for quick prototyping and low-volume with end-used quality.

• CNC Milling

CNC machining operations can incorporate intricate design, detail, and textures into the mold tool.

• Electro-discharge machining

EDM is ideal to create the unconventional features that traditional milling machines cannot produce. It is widely used to produce molds and it can be precise.

Rapid tooling is used in virtually every aspect of industrial manufacturing, low-volume production, and product prototyping. The following industries can use rapid tooling:

• Automobile

• Aerospace and Aircrafts

• Construction

• Consumer Electronics

• Consumer products

• Military/Defense

• Energy and Power

• Medical

• Transportation

• Education

At Premium Parts, rapid tooling is mostly accomplished with Aluminum and Steel alloys. Here are some of the properties of both type of materials:

Depending on the material used, the material to be molded, cast, and design geometry, Premium Parts can finish your parts in various ways. Some of our finishing solutions for rapid tooling include:

• Texturing

• Commercial Polishing

• Mirror Polishing

All our tooling solutions are designed with considerations around the surface finish guidelines of plastic injection molding and pressure die casting.

1. How long can you store our tooling before the next order?

We can store your tooling for up to 5 years, after your last order.

2. If our tooling was broken before the expected quantity molded, what can you do for us?

Generally, if our tooling was running out of its’ tooling life, we can remake another new mold free of cost.

3. Can I export my tooling?

Please let us know the tooling would need to be exported when you inquiry. We would need to quote the independent mold so you can export it.

4. What’s the typical life of rapid tooling?

It bases the material we used for mold making. For mold with aluminum, it can mold around 10,000 units. For mold with steel, it can mold 50,000 to 100,000 units roughly.

X

X