♦It adopts stainless steel shell and anti-corrosion sterile stainless steel process connection to meet the sanitary level measurement requirements.

♦The maximum temperature resistance is 150℃~200℃.

♦It is easy to use, does not need to be disassembled during cleaning and high-temperature sterilization, and is easy to operate.

♦Supports 4-20mA/1-5vdc analog output and Hart, RS232, RS485 digital communication.

PM425 Sanitary Tri Clamp Medical Flush Diaphragm Pressure Sensor

PM425 pressure transmitter is designed with full sanitary stainless steel and stainless steel seal. Hygienic design complies with EHEDG/GMP standards. Suitable for food, beverage, pharmaceutical and bioengineering industries with special requirements.

Application: CIP-SIP process control; food, beverage, medicine and other health fields and fine chemicals

Technical Specification

| Range | -0.1MPa...0kPa~10kPa...100MPa | ||

| Fluid material | Standard: 316L stainless steel ceramics, typical: khashi alloy or gold plated diaphragm | ||

| Display range | -1999~9999 | ||

| Accuracy | 0.1% (custom), 0.25% (typical), 0.5% (maximum) | ||

| Temperature Drift | ≤±0.05%FS/°C (temperature range -20~85°C) | ||

| Zero point | ≤±0.02%FS/°C (Typical), ≤±0.04%FS/°C (Max) | ||

| Full point | ≤±0.02%FS/°C (Typical), ≤±0.04%FS/°C (Max) | ||

| Compensation temperature | 0°C~50°C(≤100kPa), -10°C~70°C(>100kPa) | ||

| Heat return difference | ≤±0.5%FS | ||

| Filling flfluid | 1. Silicone oil 2.Synthetic oil or sanitary oil | ||

| Response time | Current output max. 2ms, Voltage output max. 10ms | ||

| Storage temperature | -40°C~125°C | ||

| Medium temperature | -30°C~300°C | ||

| Mechanical impact | 100g/1ms | ||

| Mechanical vibration | Max. 20g: 15~2000Hz | ||

| Power supply | 12 ~ 36VDC (Power consumption of 30mA) | ||

| Output Signal | Analog output: 4mA~20mA (superimposable HART protocol).0V~10V | ||

| Digital output: RS485 | |||

| Control output: Switch: 2 way, analog quantity: 1 way | |||

| Load error | < 0.5% | ||

| Protection leve | IP65/IP67 | ||

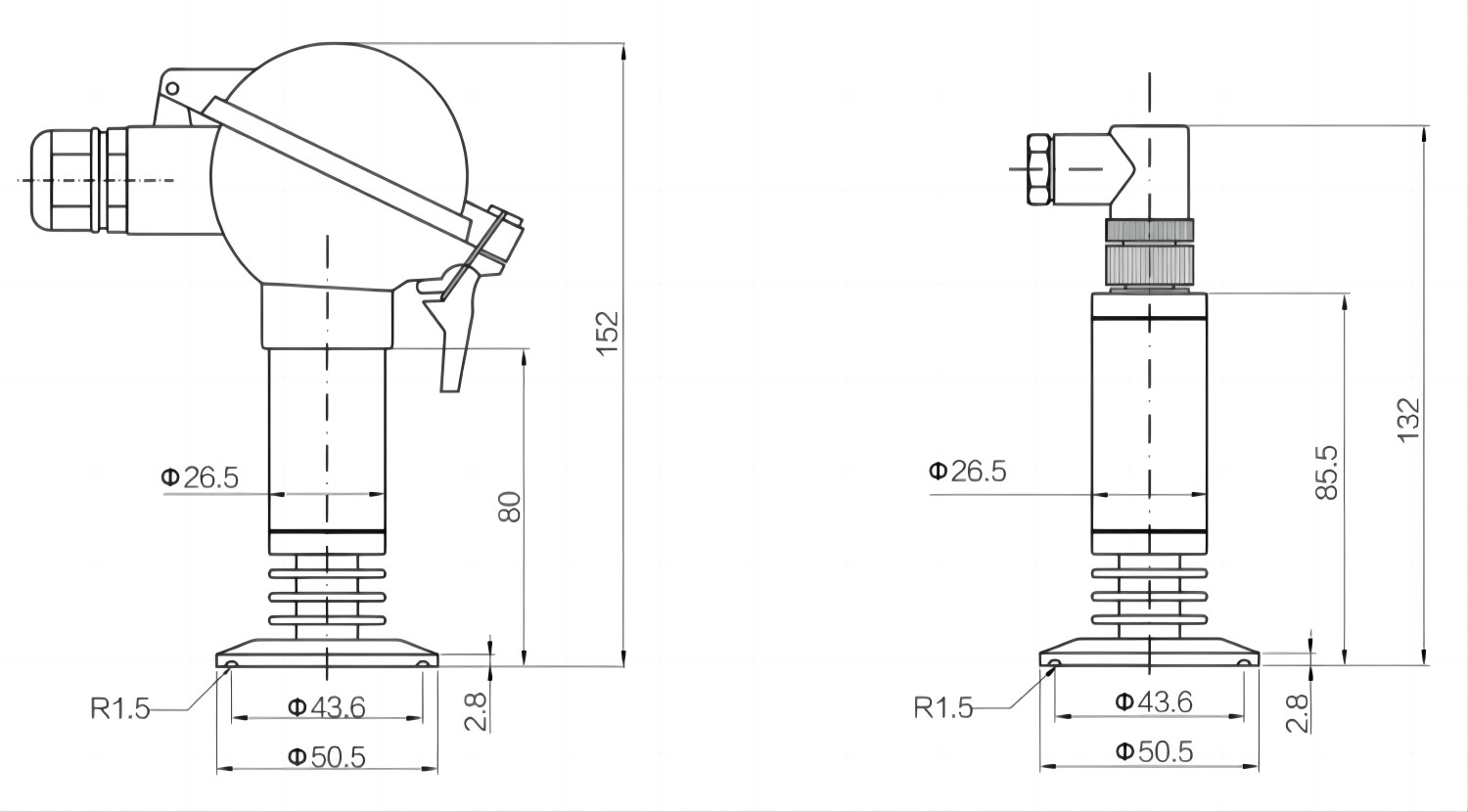

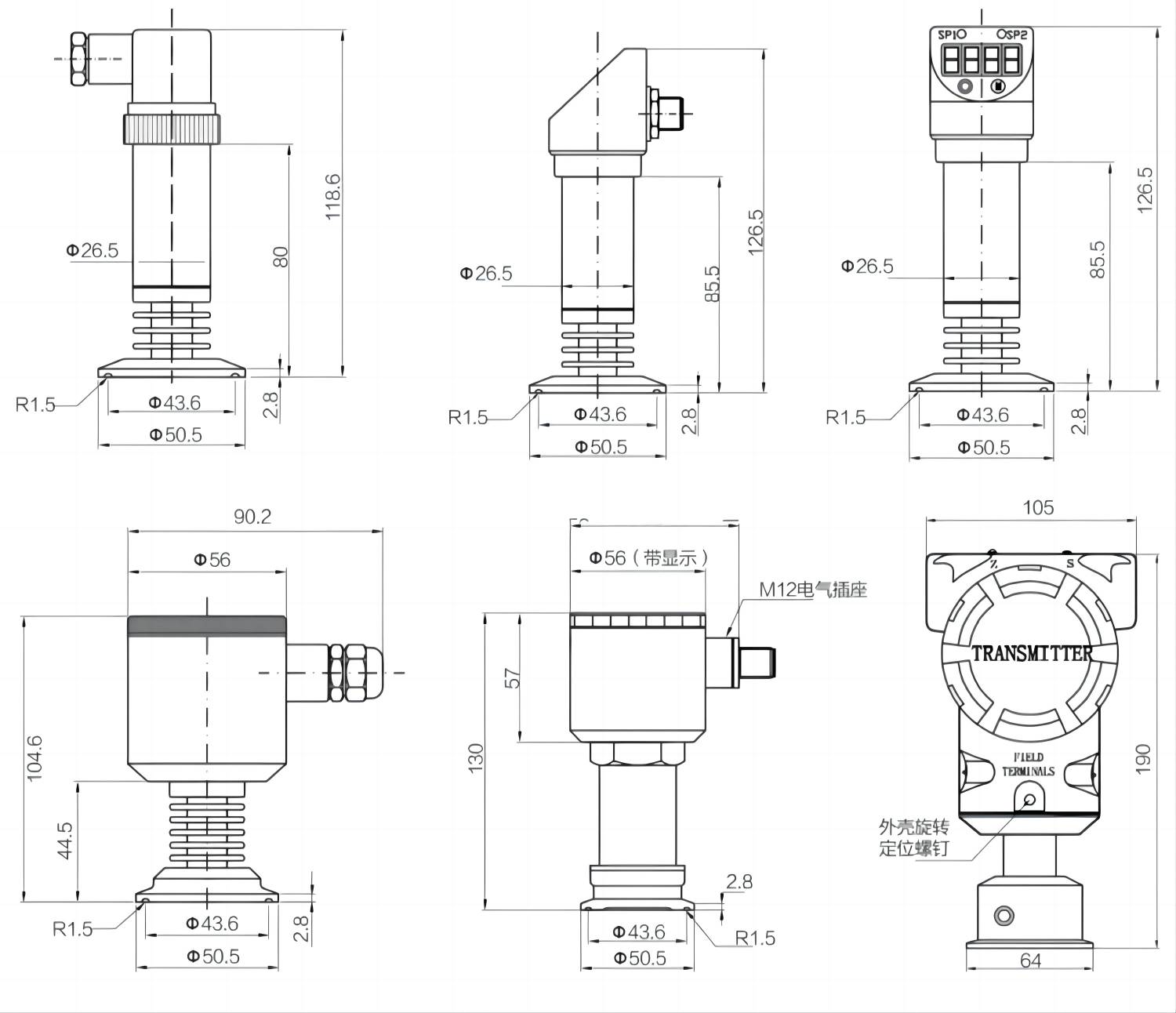

Product Display

FAQ

Can you produce according to the samples or drawings?

Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

What is the lead time?

For standard models, lead time is about 3~5 days after order confirmed and payment received.

For OEM orders, the delivery is about 2~3 weeks after data confirmed and payment received.

How to solve the quality problems after sales?

Take photos or videos of the problems and send to us.

We will make a satisfied solution for you within 24 hours after we confirm the problems.

X

X