Most PCBs used in automobiles are 4-layer, 6-layer, 8-16-layer boards. The production requirements for automotive electronic PCB boards are not much different from ordinary PCBs in design. The defect rate is mainly reflected in the process. The PCB is low, and the requirements for vibration and high temperature performance are higher.

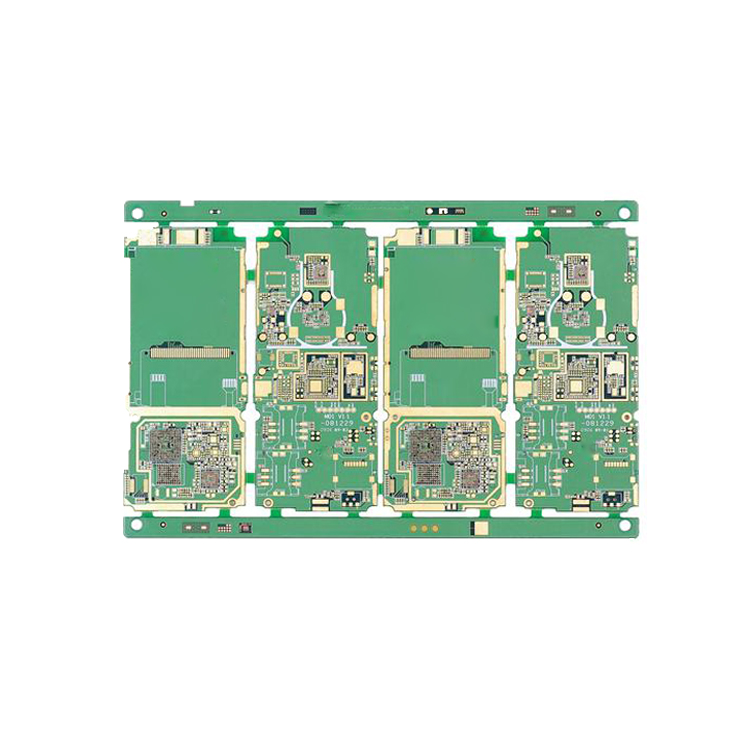

PCB Manufacturers For The Automotive Industry

With the development of new energy vehicles and intelligent driving technology, the demand for PCBs for automobiles will increase substantially. Pure electricity and hybrid power, and fuel cell vehicles require high-current thick copper PCBs, while intelligent driving radars require high-frequency PCBs, car GPS navigation PCB circuit boards, and surface treatment generally uses heavy gold, which can effectively block copper metal and air Prevent oxidation, can enhance the reliability and stability of automobile circuit board.

FAQ:

Q: I have not any file, can you produce it for me?

A: Just contact our sale manger, they will collect your requirements/idea to evaluate for our engineers.Finally, we will give you reply and the solution within 48 hours.

Q: What payment methods can you accept?

A: For sample order, recommend you use Paypal, Xtransfer and Western Union etc.. For mass production order, we can accept t/t, L/C and D/P etc..

Q: How can we guarantee automobile PCB quality?

A:

X

X