NIR Nuts Optical Sorter integrates advanced visible light and InGaAs invisible light sorting technologies.It can sort the kernel from shell even they are same color,including pecan,walnut,almond etc.

The materials selected by infrared are mainly aimed at the same-color foreign objects that are difficult to be identified by visible light.

Providing sorting solutions for all kinds of nuts and shells separation ,like walnut ,pecans etc.

HIGHTECH Nuts Optical Sorter integrates advanced visible light and InGaAs invisible light sorting technologies.

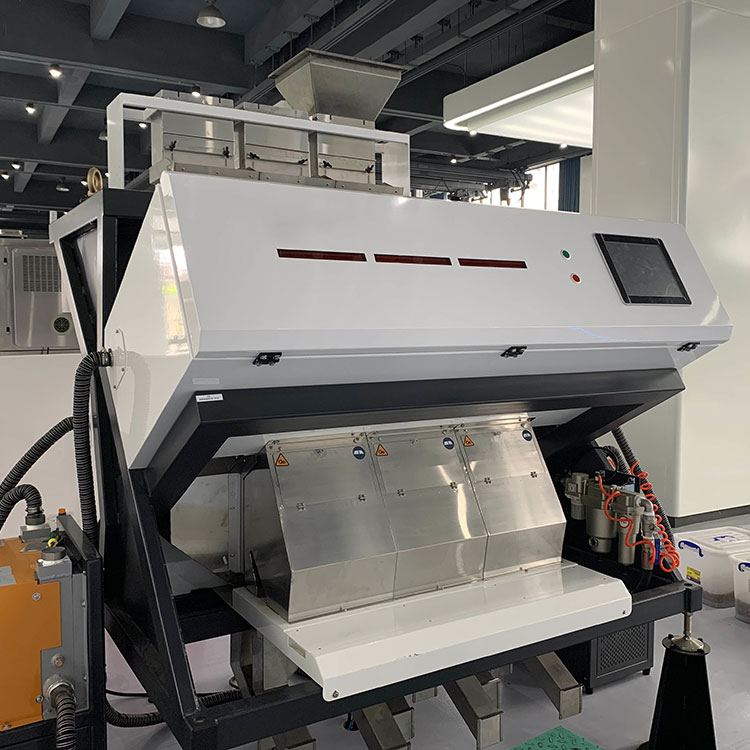

I series nuts color sorter is mainly used for separate all nuts kernel and shells.

The colors of nuts and shells are similar, and it is difficult for ordinary visible light cameras to identify them. Usually infrared spectroscopy technology is used for sorting, but infrared has a week recognition effect on dark shells, so composite visible light is also required .

Effective sorting applications: peach kernels, almonds, walnuts, pine nuts, almonds

| Model |

I1 |

I3 |

I5 |

|

Product Output(t/h) |

0.5~1.5 |

1.5~3 |

2.5~4.5 |

|

Sorting Accuracy(%) |

≥99 |

≥99 |

≥99 |

|

Weight(kg) |

600 |

1028 |

1460 |

|

Power(kW) |

2.5 |

3.7 |

5.9 |

|

Dimension L×W×H(mm×mm×mm) |

1064×1707×1827 |

1554×1707×1827 |

2184×1707×1827 |

|

(Power Supply)(V/Hz) |

220/50(110/60) |

220/50(110/60) |

220/50(110/60) |

Based on prism splitting dual-band infrared light spectroscopy technology, it can effectively realize the separation of kernel shells from various nuts such as walnuts, almonds, peach kernels, pine nuts, and hazelnuts.

Perfect integration of visible-infrared composite technology, infrared and visible light are independently set, for black objects that cannot be recognized by infrared, visible light can be eliminated simultaneously.

Equipped with a high-performance halogen lamp constant temperature cooling system, the product stability is higher, and the sorting effect is more stable .

Packaging & Shipping

Machines to be carefully packaged to endure transportation under harsh conditions. Handling instructions are designed to protect the machine in the critical moments during transportation, unloading and installation.

Delivery Time: 10- 20 Days after order confirmed.

Payment Terms: TT, Letter of Credit.

Commissioning and Installation

1. On Site Installation and Training Service by our professional engineer ;

2. Study and Learn the Machine Operation in Our Factory.

3. Responsive in 24 hours: Telephone, Email, Video or On Site Solutions by our Technical Experts.

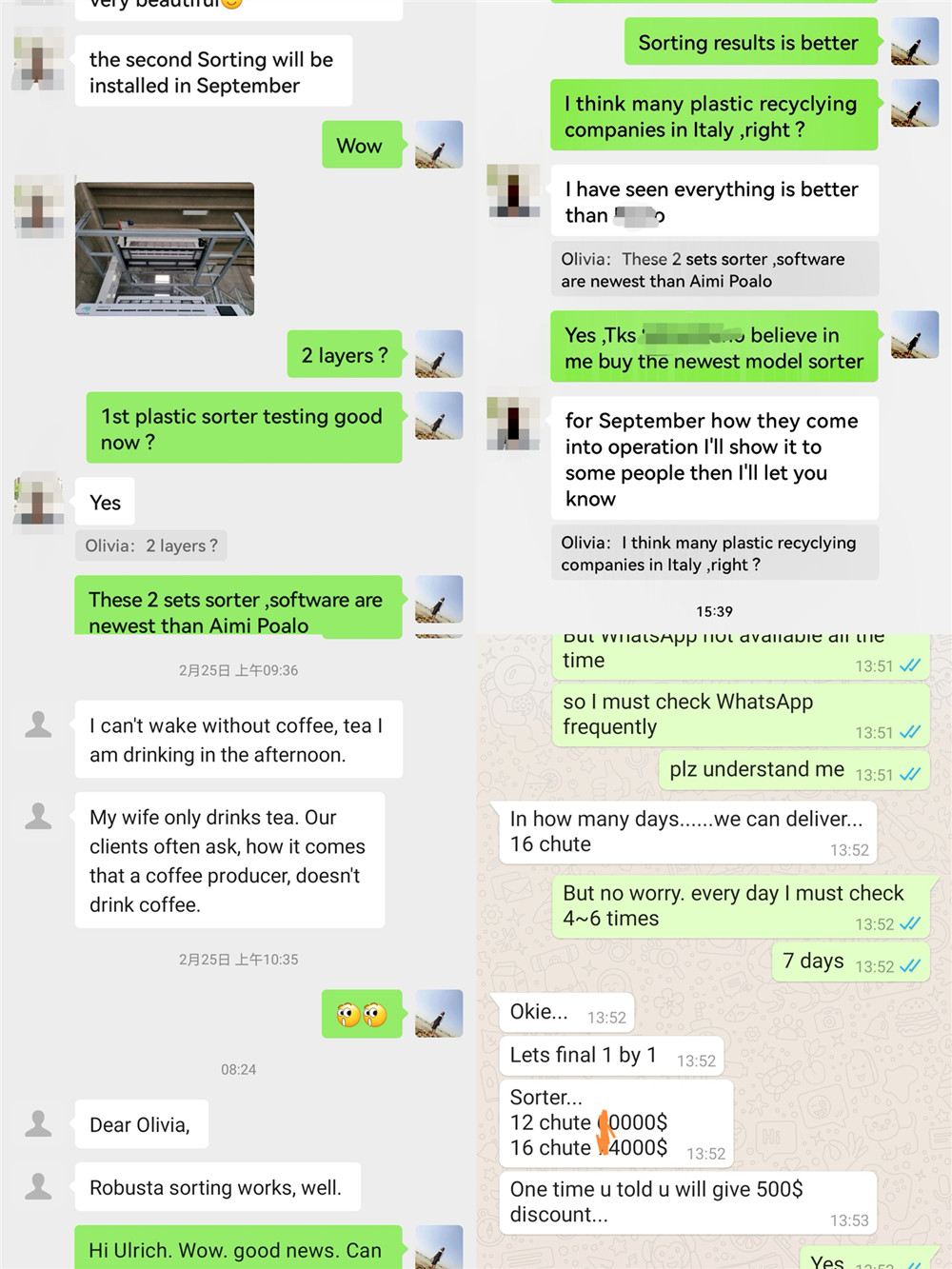

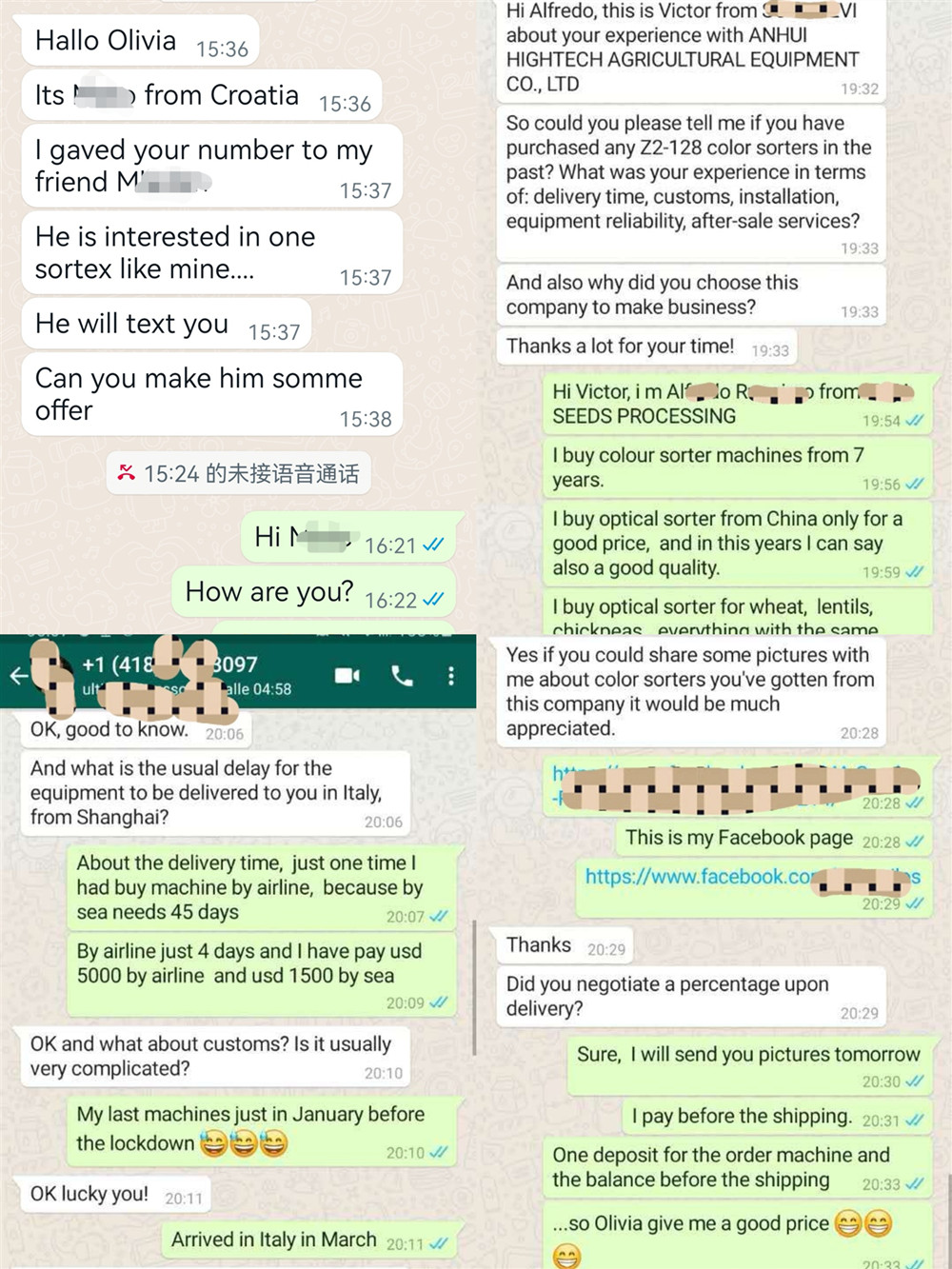

Customer feedback is the driving force behind our progress:

Plywood Case is Suitable for Sea/Road/Air Transport:

1. How to use the machine?

We will supply the Installation instructions and videos for guiding you how to set color sorter.

2. How long about the guarantee period?

Two years. And we supply lifelong software upgrade services for our customers.

3. Can you supply the air compressor, air tank and air filters?

Yes, we can provide above equipments, our standard offer includes color sorter machine with air compressor & air tank & air dryer & air filters.

4. Is oversea service available?

Yes, we will send engineer go abroad when you need it.

5.How to calculate Installation personnel cost?

On condition that customer requires to install, our company would like to send 1 engineer to guide for installation, then customer should to pay the cost, including transaction of engineer’s visa, transportation(air) for go abroad. and accommodation , local transportation and security when the engineer arrived.

6. If you have agent in our country?

We have agent in UK,New Zealand,Italy,Crotia,India, Guatemala,Finland,Malaysia,Bangladesh,Pakistan,Nigeria,Ukraine,Nicaragua etc. and we can provide after-sales service in your Country.

X

X