DNW-SN08 Low Price Super Conductive Layer Sanitary Napkin Making Machine

|

Subject |

Parameter |

|

Stable Working Speed |

600-1200pcs/min (By order) |

|

Pass Percentage |

≥98% |

|

Operating Rate |

≥85% |

|

Power Supply |

380V 50Hz |

|

Electrical Supply |

380V ±5%, 50Hz Three-phase four-wire + ground wire |

|

Power Installed |

About 180KW (Not included hot melt glue machine) |

|

Supply Pressure |

0.6-0.8Mpa |

|

Machine Sizes (L× W× H ) |

22.0m× 5.5m× 3.5m(L× W× H )(Only for reference) |

|

Main Engine Sizes (L× W× H ) |

32m× 9.0 5.0m (L× W× H ) ( Only for reference) |

|

Machine Color |

Customerized |

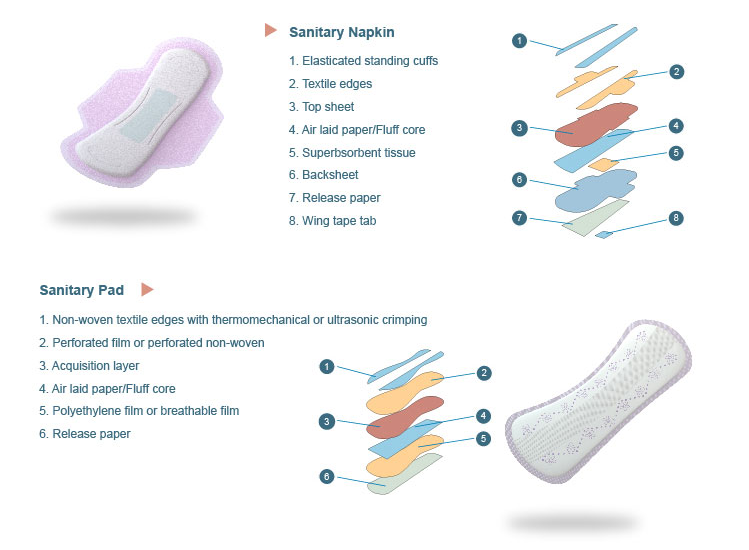

Product Structure

1. The lower toilet paper wraps the cotton pulp polymer, the surface layer, the bottom film, the middle paste release paper, and the wing release paper small package film.

2. Product specifications: 240-350mm (can be customized according to customer requirements)

3. Control system: PLC control, using touch screen to operate man-machine interface, equipped with LED digital display, to realize graphic digital operation.

4. Tension system: equipped with tension unwinding system, constant tension control and storage mechanism, material deviation correction system. This set of constant tension system ensures stable material receiving at full speed, minimizes the impact of material tension and reduces the number of shutdowns.

5. Transmission system: It adopts full servo drive and digital number changing, which is convenient and quick. The timing belt and flat belt are all imported, and the key parts are all imported bearings.

6. Safety system: The operation surface is equipped with safety protection devices and safety signs, each section is equipped with an emergency stop switch, and the rear transmission is equipped with a heat dissipation system and a safety cable.

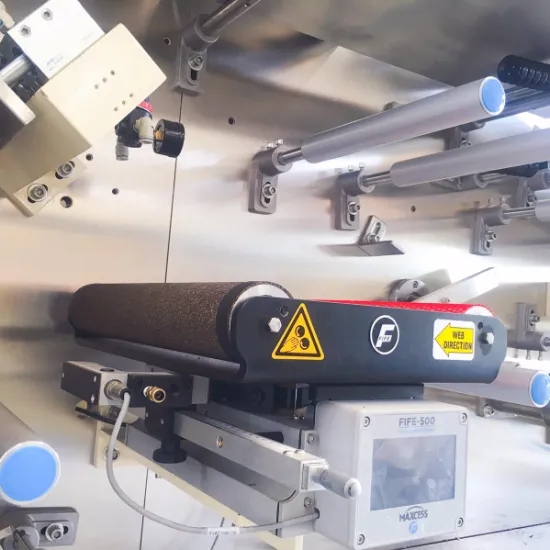

7. Correction system: adopts the correction system of internationally renowned brands

Automation Configuration

1.Back side driving has two layers. Change the sizes just need to change 2 pcs of timing belts only.

2.Each raw material holder has frequency controlled motor for winding and unwinding,constant tension control.There is not frequency controlled motors for release paper holder,wing release paper holder and easy tape holder.(There are 12 set of frequency controlled motors for raw materials)

3.Temperature controlled by sensor and temperature controller.

4.The heating roller cylinders synchronous with machine.

5.Safety unit for all cutting tools.

Composition of Sanitary Napkin

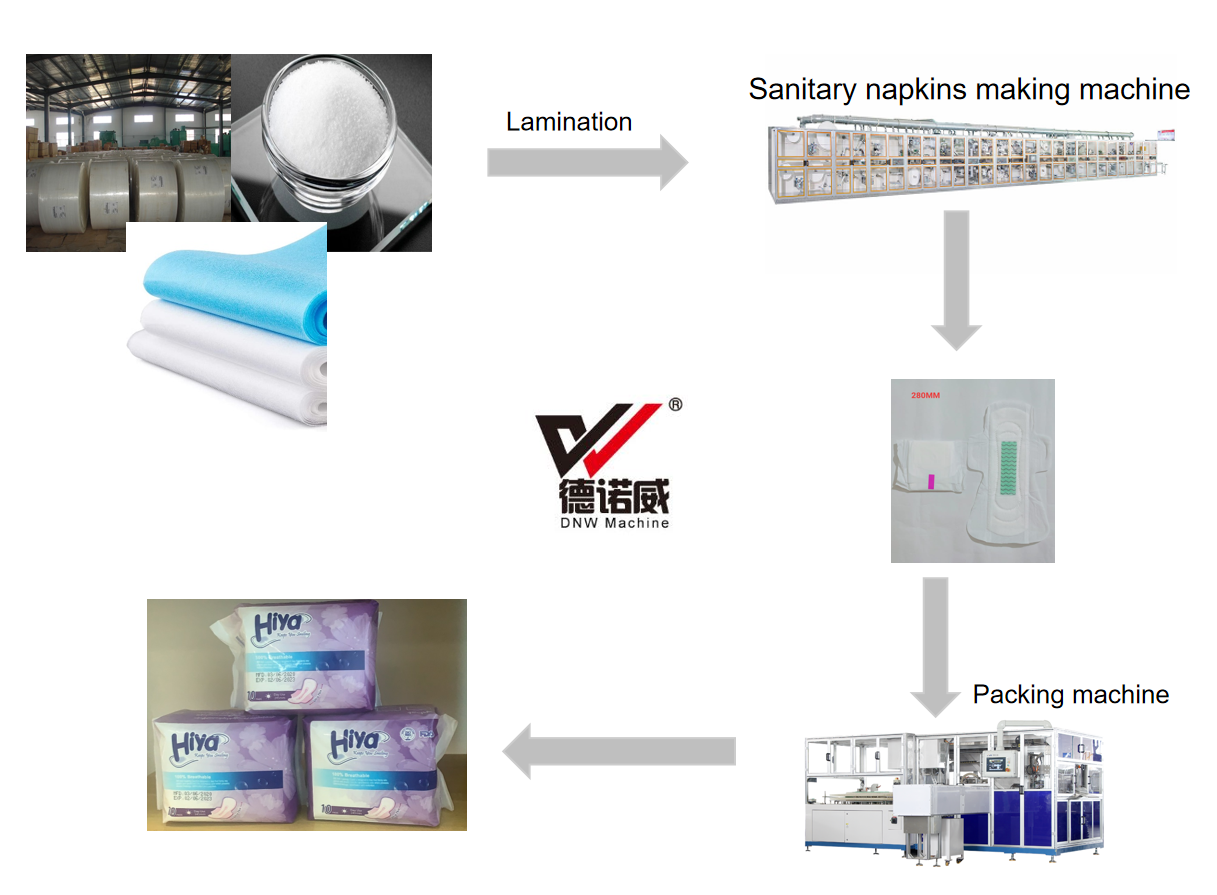

Production Process

FAQ

1. Are you technologically advanced?

A: We have 20+ years of experience and have been leading in our field. Greatest technological advancement is people, we have over 450 employees, including 150 specialized technicians and R&D staff.

2. Can you do the machines' appearance design for us?

A: Yes. We have a professional team with rich experience in machine's appearance design and manufacturing. Machine structure design is according to the products that you want to produce.

3. Could you also supply raw materials?

A: Yes, of course we can. We are a supplier of machines, raw materials and finished products, providing a whole supply chain. We can offer you good quality and good price. This is our service chain.

X

X