Retractable Flap Barrier is designed to solve the common issue which happened in commercial buildings and other facilities like quick pass of employees and visitors, protect facility property.

High Throughput Retractable Flap Barrier Gate

LD-Y605 Retractable Flap Barrier is designed to solve the common issue which happened in commercial buildings and other facilities like quick pass of employees and visitors, protect facility property. It combined access control management software, by check pedestrian information, prevent un-authorized entry and allow authorized entry and register timing. It is the perfect access control security gate for aesthetic environment such as corporate offices, Banks, IT companies....

Retractable Flap Barrier is a user friendly automatic security gate, which consists of two cabinet with an acrylic panel as visual physical barrier to create high-speed pedestrian walkways. And in double lanes or dual lanes, there are two barriers in one cabinet. Flap barrier gate is used in single lane and multi-lanes based on site requests. And multi lane flap barrier gate for high throughput requirements.

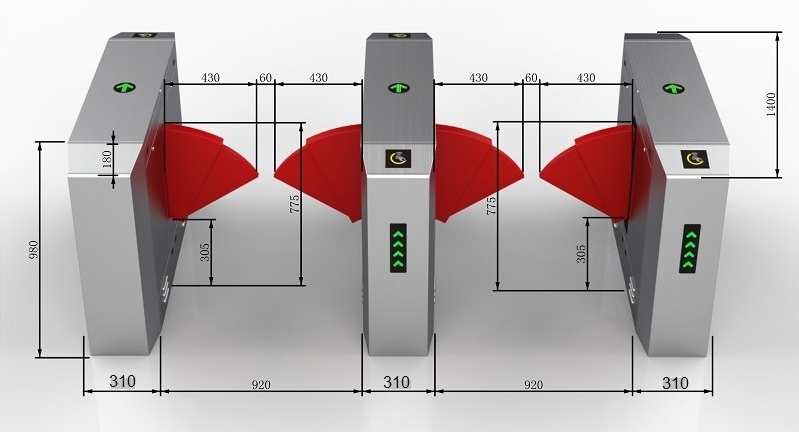

Parameters of LD-Y605

Moduel No.

LD-Y605

Size

1400*310*980mm

Material

304 stainless steel, PU, acrylic

Access width

900 mm

Input voltage

100V ~ 240V

Drive motor

DC 24V brushless motor, low noise

Passing speed

35 people / minute

Applicable temperature

: -20~70℃

Life Time

9 million times;

The material thickness

1.2mm / 1.5mm

Response time

<1s

Infrared Sensor

5 pairs

Access direction

One-way / two-way

Opening methods

ID/IC card reader, infrared induction automatic opening, button opening, etc.

The standard passage width of single lane flap barrier gate is 550mm, but LD-Y605 can be more than 900mm wide, capable for handicap passage like wheelchairs. In order to minimize the damage caused by the retractable barrier, the wing panels can also be replaced with a soft wing made of PU material.

Features of flap barrier gate movement

1. The movement is highly versatile, and can also be matched with a brush motor or brush-less motor, using two mechanical dead positions to limit. Can be used with brush motor, with hall switch, induction magnet, long sensing distance

2. Connecting rod structure, all-round bearing parts, high accuracy, low noise during work, low wear, and strong durability

3. Full-height bracket, with traction up and down, the movement is stable in the chassis, and the vibration and noise generated are relatively low.

X

X