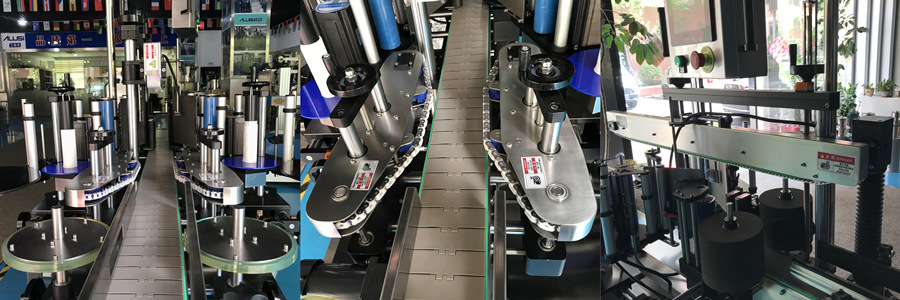

The servo motor economy automatic Sticker Labeling Machineis suitable for all kinds of regular and irregular containers, flat surface or round bottles, especially ideal for flat surface and square containers.

Main Features:

1. Sticker Labeling Machine adopt mature PLC control system technology, make the whole machine stable

2. This type of Automatic Labeling Machine can be suitable for square /round/oval flat bottles at the same time, Of course client can choose to make one side or double sides labeling.

3. Use touch screen control system, record bottle date,

4. Conveyor with variable speed.

5. Synchronization chain mechanism, to ensure smooth and precise calibration,

6. Transparent sticker labeling without foam, adhesive sticker labeling without wrinkle,

7. Widely used and mutil-function with high flexibility,

8. Date/code printeris for optional,up to 3 lines, or you can choose inkjet printer.

9. Tranparent label sensor is for optional,

10. Can be customized according to your requirement,

11. Other match equipment: Automatic Cream Filling Machine, Automatic Capping Machine.

* Powerful function, one machine can realize 4 products labeling(square, round, flat and dysmorphic bottle)

Process:

put the bottle(can be linked with the production line)—>product orientation(automatically)—>product delivery(automatically)—>labeling(automatically)—>collect the labeled bottles.

|

No |

Item |

Description |

|

1 |

Label roll inner diameter |

φ76mm(customized) |

|

2 |

Max Label roll outer diameter |

φ370mm(customized) |

|

3 |

Label Height |

10-190mm(optional) |

|

4 |

Labeling speed |

36/min(adjustable) |

|

5 |

Material |

Stainless steel 316&304 |

|

6 |

Automatic Grade |

Automatic |

|

7 |

Driven type |

Electric |

|

8 |

Power Supply |

380V,50/60HZ,3000W |

Advantage:

* The Double Sides Labeling Machine, provided with such mechanism as bottle Piloting, bottle dispensing and labeling, and counting etc,is most suitable for use of small amount of various products or for operation of single machine and single person. The labeling position, height and angle can be adjusted. It can be connected by conveying belt with the production line.

* With failure warning function, auto-counter technology, power saving function(the equipment will automatic turn to power saving holding state while no production in setting time),the production number setting hint function and parameters setting protection function(parameters have authority management)

Package & Delivery:

Our Servers:

We provide Turn-key project service to customer.

1. Factory Layout design;

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, Maintenance service.

X

X