Applications:

Recommended for applications both in open air and underground power distribution cables with PVC ,lead or XLPE sheaths.

Features:

Technical properties

|

Test Items |

Test Method |

Test Requirements |

|

Tensile strength |

ASTM D 2671 |

12MPa min. |

|

Ultimate elongation |

ASTM D 2671 |

200% min. |

|

Volume resistivity |

IEC 93 |

1014Ω.cm min. |

|

Dielectric strength |

IEC 60243 |

12kV/mm(1.0mm) min. |

|

Water absorption |

ISO 62 |

0.5% max. |

|

Heat shock at 225℃/4hrs |

ASTM D 2671 |

No cracking, dropping |

|

Density |

ASTM D 792 |

1.0~1.1g/cm3 |

Selection table:

|

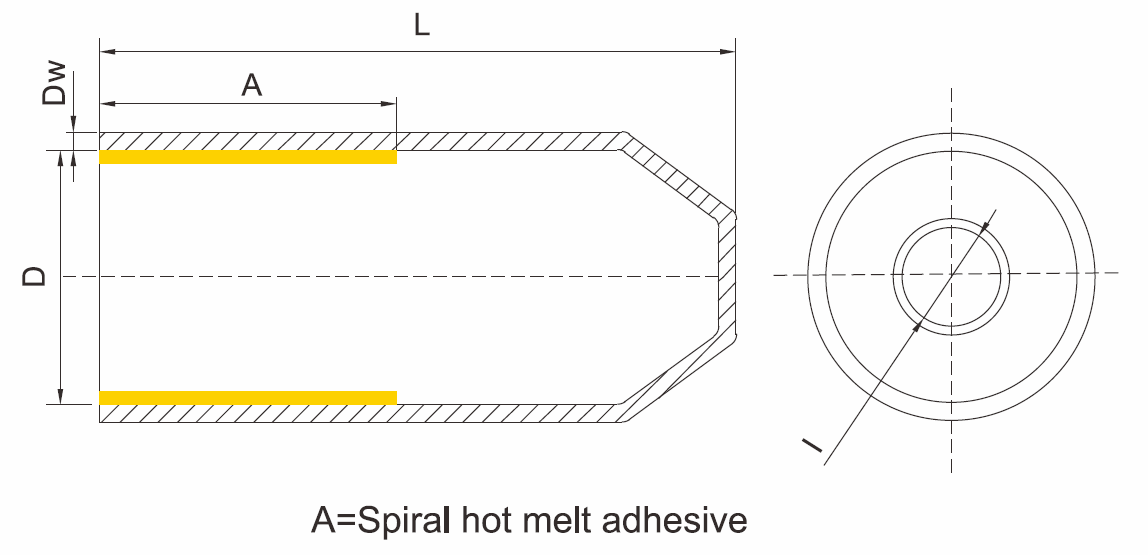

Size |

As supplied(mm) |

After recovered(mm) |

||||

|

(mm) |

L*(±10%) |

D*(Min.) |

A*(±10%) |

d*(±10%) |

l*(±10%) |

Dw(±10%) |

|

Cable end cap-HSEC, standard length |

||||||

|

HSEC 105 12/4 |

38 |

12 |

15 |

4 |

40 |

2.6 |

|

HSEC 110 14/5 |

45 |

14 |

18 |

5 |

42 |

2.2 |

|

HSEC 115 20/6 |

65 |

20 |

25 |

6 |

55 |

2.5 |

|

HSEC 120 25/8.5 |

75 |

25 |

30 |

8.5 |

65 |

2.5 |

|

HSEC 130 35/16 |

92 |

35 |

35 |

16 |

83 |

3.3 |

|

HSEC 135 40/15 |

95 |

40 |

40 |

15 |

75 |

3.3 |

|

HSEC 140 55/26 |

114 |

55 |

50 |

26 |

105 |

3.5 |

|

HSEC 150 75/36 |

132 |

75 |

55 |

36 |

115 |

4.2 |

|

HSEC 160 100/52 |

153 |

100 |

70 |

52 |

130 |

5 |

|

HSEC 170 120/60 |

155 |

120 |

70 |

60 |

150 |

5 |

|

HSEC 180 145/60 |

160 |

145 |

70 |

60 |

150 |

5 |

|

HSEC 190 160/82 |

160 |

160 |

70 |

82 |

133 |

4.5 |

|

HSEC 200 200/90 |

170 |

200 |

70 |

90 |

145 |

4.5 |

D* = Inner diameter as supplied

d* = Inner diameter after fully recovered

w* = Wall thickness after fully recovered

A* = Length of adhesive after fully recovered

L* = Length of end cap as supplied

X

X