Economical plastic injection molding machine equipped with advanced dual injection cylinder design.

Product Advantages:

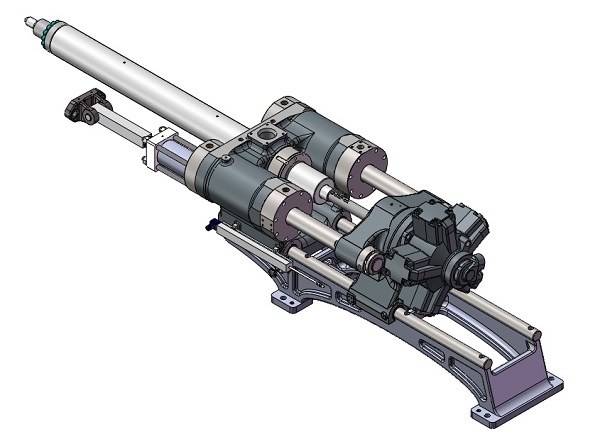

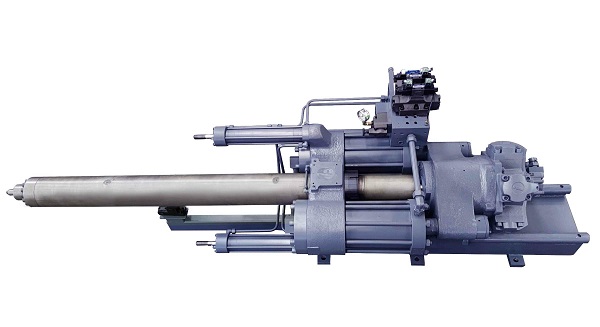

GM2 series plastic injection molding machine equipped with advanced dual injection cylinder design, which is economical type machines in Lanson company.

Optimized design for injection unit

The design of traditional twin-cylinder is optimized, employ the arched intergrated injection unit instead of conventional two-point support, improving the overall rigidity of the injection unit and having more stable injection motions. Direct connection between the control valve and the injection cylinder, leading to rapid movement response.(Machine above 320T equipped with double injection carriers)

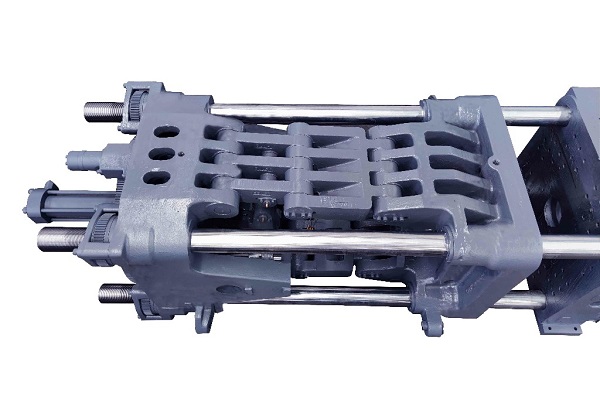

Reinforced clamping unit

Maximum increase the fixed platen and moving platen shearing surface, avoid stress concentration. Beside, we increase the number of hinges, hinge pins and steel jackets shearing surface.

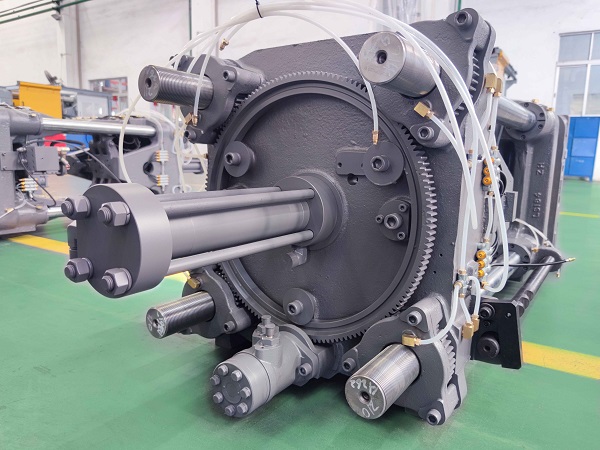

Accurate and time saving gear mold adjusting system

Employed accurate gear mold adjusting device, the mold adjusting action is smooth and fast. It can also save the mold setting time after mould changing.

Patented design for fixed platen

Adoption of box type design with maximum size, enabling small distortion of molding board.

Optimized design for moving platen

Moving platen structure has been optimized according to the actual stress conditions. Due to widened hing ears of moving platen, it transfers the clamping force evenly from the toggles to the central surface of the moving platen, then effectively to the mold, ensuring product accuracy.

Integrated toggle with long service life

Reinforced and integrated toggle by Lanson special design to achieve long service life

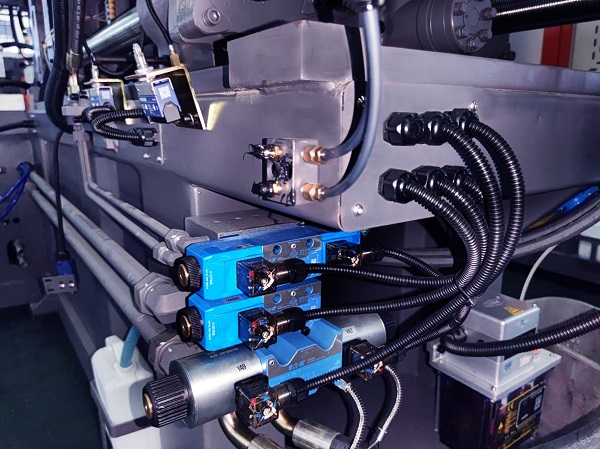

Professional cable connection

Lanson care all the small detail including cable connection so as to give a perfect machine to customers.

Linear transducer protector

Protecting the linear transducer during machine running so that life will be long.

X

X