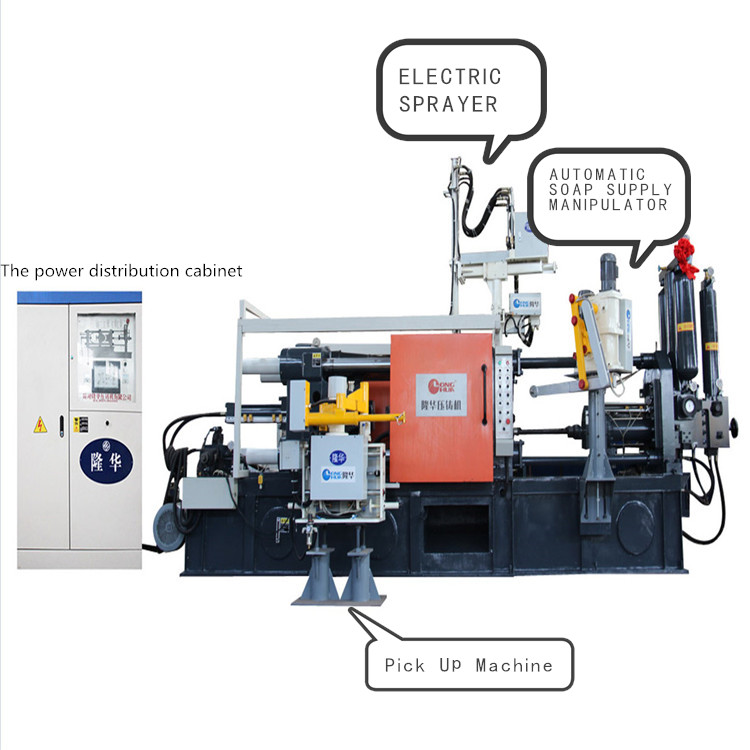

This die casting machine is widely used for mass production of foundry goods made of nonferrous metal.

computer-programmed control; hydraulic drive; crank expanding structure;4-rod pilot elastic stress framework; locking that is tensile, faster and reliable; hydraulic boosting and injecting system that is constant and effective; accumulator and injection framework are compose alone; injection rate over 4M/s, and minimum boosting time less than 30ms.

The product description

Longhua die casting machine is suitable for industrial road railway aviation agricultural machinery. Mechanical parts are processed by CNC center self to form a precision die locking system.In order to guarantee theinjection concentricity and stability, the complete cast steel structure C frame is adopted uniquely.

Product parameters

LH series of standard parameter table (350 t)

|

ITEMS |

Unit |

Specification |

|

HYDRAULIC WORKING PRESSURE |

MPa |

14 |

|

CLAMPING FORCE |

KN |

3500 |

|

SPACE BETWEEN TIE BARS |

mm |

600*600 |

|

Tie Bar Diameter |

mm |

¢120 |

|

DIE OPENING STROKE |

mm |

500 |

|

INJECTION FORCE(intensify) |

KN |

360 |

|

Plunger launch distance |

mm |

180 |

|

Injection position |

mm |

0 -- 160 |

|

PLUNGER DIAMETER |

mm |

¢50----¢80 |

|

INJECTION STROKE |

mm |

480 |

|

Casting pressure (intensify) |

MPa |

184/127/94 |

|

Casting Fiange Protrusion |

mm |

12 |

|

Casting Fiange Diameter |

mm |

110 |

|

MAX CASTING AREA UNDER 40Mpa |

CM2 |

875 |

|

lnjection Weight(Al) |

Kg |

3.8 |

|

Die Height(Min--Max) |

mm |

250~750 |

|

EJECTOR FORCE |

KN |

180 |

|

EJECTOR STROKE |

mm |

110 |

|

Motor Capacity |

Kw |

18.5 |

|

Machine Dimensions (L*W*H) |

m |

6.8*1.8*2.7 |

|

Referential Machine Weight For Uplifting |

T |

14.2 |

|

Oil Tank Capacity |

L |

700 |

WE reserve the right to make any technical improvement without further notice

Die casting machine related products

Exemption certificate for import and export inspection

X

X