Cnc Folder Roll Forming /Sheet Metal Folding Machine/CNC Folder Machine is used for plate bending and shearing usage. Setting degree in control system.

Description:

Cnc Folder Roll Forming /Sheet Metal Folding Machine/CNC Folder Machine monitoring system to make down folding process, finally manual semi-automatically work with the plain sheet to realize various steel section production. Such as trims, ridges, gutters, flashings etc…

Technical Details:

1) For Steel sheet:Aluminum coil

2) Thickness range: 0.3-1.0mm (aluminum up to 1.2mm)

3) Driven by Servo motor, pump motor: 0.82KW

4) Working length: 8200mm

5) Press clamp:9 units

6) Weight:Approx. 4500 Kg

7) Pressing power:Pump motor for hydraulic station 11KW(Located outside)

8) Bending range:0-125 degree

9) Depth of throat:1000 mm(Max. working width of material in clamp)

10) Hinge:9 groups

11) Total power:12.92KW (11KW+1.1KW+0.82KW)

12)Outline dimension(Length×Width×Height):9500×1620×1800 (For reference only)

Slitting Device:

1) Type Of Blade : Slitting wheel

Diameter:∮80

Material:Cr12MoV (D2), heat treatment

2) Drive system: motor power 1.1KW

Guiding device:Steel chain circling

3) Slitting speed:Approx.4.8m/s

Slitting distance: Through steel chain circulation.

Bending & Slitting Device:

1) Max. Bending thickness 1.0mm

2) Max. Bending length 8200mm

3) Max. Slit thickness 1.0mm

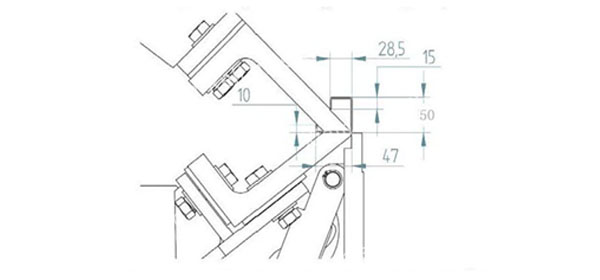

4) Min. folding dimension as below

Hydraulic power pack:

1) Capability:Max.16MPA

2) Capacity of oil tank: 460L

3) Power source:Hydraulic

PLC Control System (with running simulation system):

1) System:Austria B&R System

2) Numerical control locating system:Austria B&R PLC Control

3) Operating table:Austria B&R Touch Screen

4) Angle programmer:Encoder test

5) Slitting control:Manual

6) Emergency stop: e-stop button+ e-limit+ foot switch (right heavily)

Cnc folder controler:

Sheet metal folding rollformer machine:

X

X