Hand-built 700C carbon wheelset rim brake with DT Swiss 240 EXP hubs and aero Sapim CX-Ray spokes, which is light, stiff, durable and easy to maintain, Perfect transmission of your power and reliability, suitable for professional riders or racers.

The U-shaped cross-section design, carbon 700C road rim brake wheels with DT Swiss 240 Ratchet EXP hubs Direct power transmission in every riding situation. We have different depths, 38/50/60/88mm and 27mm outer width, 20mm inner width carbon wheels. 38 mm depth is usually used for climbing and the 50/60/88mm depth is designed for riding competition. Compatible with tubeless option can improve rolling resistance, comfort, traction and reduce the propensity for flat tires. suitable for professional riders or racers.

FEATURES:

FEATURES:

- Aerodynamic advantage

- Double wall design, for better strength and stiffness

- Compatible for both normal tube tire and tubeless tire

- High TG 255°C braking surface

- Hubs optional: DT Swiss or Powerway hubs

- Sram XDR or Shimano 11S and Campy 11S driver bodies

- 2 years' quality warranty

SPECIFICATIONS

Max Tire Pressure(with 25C)

Model

Orn727-38C

Orn727-50C

Orn727-60C

Orn727-88C

Cross Section

Sectional Drawing

Material

T800

T800

T800

T800

Use

Road

Road

Road

Road

Type

Clincher

Clincher

Clincher

Clincher

Tubeless

Ready

Ready

Ready

Ready

Internal/External Width

20mm/27mm

20mm/27mm

20mm/27mm

20mm/27mm

Depth

38mm

50mm

60mm

80mm

ERD

568mm

544mm

524mm

468mm

Weight

465+/-15g

500+/-15g

515+/-15g

710+/-15g

Weight Limit

125kg

130kg

135kg

145kg

Spoke Tension

100 ~ 110kgf

100 ~ 110kgf

100 ~ 110kgf

100 ~ 110kgf

110psi / 7.58bar

110psi / 7.58bar

110psi / 7.58bar

110psi / 7.58bar

Tire Recommended

25C ~ 35C

25C ~ 35C

25C ~ 35C

25C ~ 35C

700C CARBON WHEELSET DT240 HUB RIM BRAKE WITH 27MM WIDE CLINCHER RIM

|

Model-Wheels |

Rim |

Depth |

Outer Width |

Hub |

Front Size |

Rear Size |

Spoke |

Weight (+/-3%) |

|

240S-ORN727/38C-CX-Ray |

Orn727-38C |

38mm |

27mm |

DT240 Road |

5 x 100mm |

5 x 130mm |

Sapim CX-Ray |

1465g |

|

240S-ORN727/50C-CX-Ray |

Orn727-50C |

50mm |

27mm |

DT240 Road |

5 x 100mm |

5 x 130mm |

Sapim CX-Ray |

1535g |

|

240S-ORN727/60C-CX-Ray |

Orn727-60C |

60mm |

27mm |

DT240 Road |

5 x 100mm |

5 x 130mm |

Sapim CX-Ray |

1565g |

|

240S-ORN727/80C-CX-Ray |

Orn727-80C |

80mm |

27mm |

DT240 Road |

5 x 100mm |

5 x 130mm |

Sapim CX-Ray |

1955g |

* All clincher rims are tubeless ready.

* Complete wheelset weights are subject to a ±3% variance.

* If you can't find the specs you need, please contact us directly to see what we can do, we will do our best to help you.

* Choose your favorite carbon rim model and Hubs, leave a message below with the wheels item number (such as 240S-ORN727/38C-CX-Ray) to get the best quote for your next carbon road wheelset!

| HUBS |

Spoke |

Nipples |

Driver Body |

Front Axle Size |

Rear Axle Size |

Front Count | Rear Count |

|

DT SWISS 180 Ratchet EXP 36 |

Sapim CX-Ray |

Sapim Self-Locking |

Shimano 11S or Sram XDR |

5 x 100mm QR | 5 x 130mm QR | 20H | 24H |

|

DT SWISS 240 Ratchet EXP 36 |

|||||||

|

DT SWISS 350 Ratchet 18 |

Sapim Race |

Sapim Self-Locking |

Shimano 11S |

||||

|

Powerway-R51 |

Pillar 1420 or Pillar 1423 |

Pillar |

Shimano 11S or Campy 11S |

||||

|

Powerway-R36 |

TECHNOLOGY

1. High TG 255°C Brake Surface

High TG resin temperature 255° brake track, solve the heating problem on the rim brake clincher bicycle wheels.

2. Tubeless Compatible Technology

The bump on the rim bed helps to create a buffer during tire inflation, making the mounting process easier. The bead locks allow for an easy switch between clinchers and tubeless setup.

3. Ultra Smooth Inner Wall

Use specific, thinner, high-pressure air bladders to control the inner wall smoothness, The result is that we could see a very clean and smooth inner wall, which means the carbon fabrics are stretched smoothly and optimized. This could ensure the best strength of the fabrics.

4. Fast Tire Installation

Easy installation and removal of normal tube tires and tubeless tires.

5. Double Wall Design and Aero Technology

We use a double wall design to better control the rim strength and stiffness during layup. Rim profiles are specially designed with aero gains and drag reduction in mind.

6. Customized Spoke Hole Angle Drilling Technology

High-speed CNC machine tools drill carbon fiber rim spoke holes. Customized according to the geometric angle of the hub. Check all drill holes to make sure they are free of burrs.

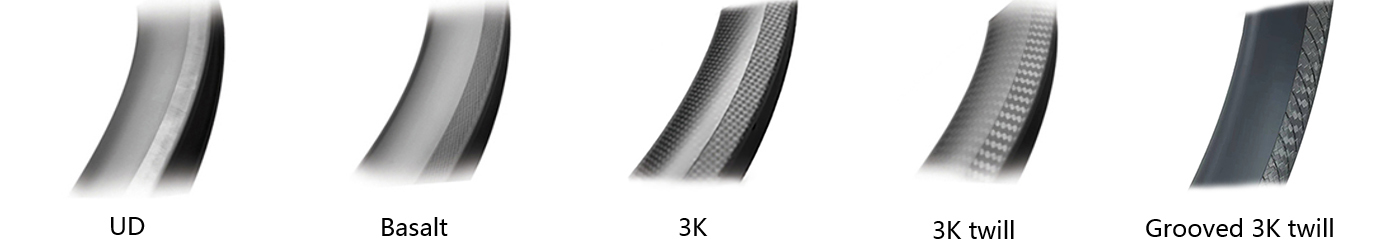

CARBON 700C RIM BRAKE WITH DIFFERENT BRAKING SURFACES

BRAKE SURFACE:

We have 5 different brake systems for professional cyclists to choose from. The high TG resin temperature of the 250° brake track solves the heating problem on the bicycle wheel of the rim brake.

If you have special requirements for the brake system, Grooved 3K twill will be your best choice.

The grooved track helps to evacuate trapped moisture between the brake pad and carbon rim under wet. it bears a higher temperature while braking, but for faster braking heat elimination. More friction, less lever force needed, and shorten about 30% braking distance. More friction to shorten the braking distance.

MANUFACTURING PROCESS:

Our carbon fiber rims are formed in one piece, and each rim is made of long carbon fiber without wrinkles, to make the strength of the rim is the strongest. Every component, including the rim serial number, airbag, and carbon fiber prepreg, is collected, inspected, and weighed to confirm that everything has been taken into account.

Read more about carbon rim manufacturing process: link here

100% QUALITY INSPECTION:

In the production process of each carbon fiber rim product, Ornanbike strictly conducts 100% quality inspection and records it in the database. Each carbon fiber rim has a unique ID number, which allows us to provide the highest quality products and track each rim To ensure the best after-sales service.

Read more about carbon rim quality control: link here

WARRANTY POLICY:

Coverage: 2-year warranty from the date of purchase.

Conditions:

1. The Standard Warranty program is not transferable and only applies to the initial purchaser. Valid proof of purchase, pictures of the defect, video, and the product serial number is required for a warranty claim.

2. If any manufacturing defect occurs within 90 days of the date of being received, Ornan Bike is obligated to replace the carbon rim and pay for the shipping cost. If any manufacturing defect occurs after 91 days and up to 2 years, Ornan Bike is obligated to replace the carbon rim, and the customer is responsible for the shipping costs.

3. Any problem found on the warranty replacement product should be claimed within 7 days after the replacement is received, otherwise, the replacement is viewed as settled. The warranty period applies to the original purchase date and does not reset with a replacement rim.

Warranty coverage does not cover:

1. Normal wear and tear (spokes, nipples, rim tape, decals, stickers, etc).

2. Improper assembly or maintenance, including maintenance by an unauthorized technician.

3. Damage or failures caused by a crash, accidental damage, misuse of the product, non-compliance with manufacturer specifications of usage, or any other fractious reasons.

CLAIMS FOR DAMAGE OR LOSS OF SHIPMENT:

Please thoroughly inspect the package before signing.

1. If there is no damage, sign for the product. If there is damage, report this on the delivery slip or, alternatively, refuse the shipment and it will be returned to Ornan Bike. If a claim is made against the shipping company, they will provide a compensation number. Please inform Ornan Bike of this number for delivery tracking. Arrangements for reshipment will be made within 10~15 business days upon receiving the returned item.

2. If the items are damaged but accepted and not reported, there is no recourse against the delivery company and you are responsible for purchasing any replacement product.

3. If the package is in good condition, but the product is significantly damaged in transit, please keep the waybill, packaging and the shipment gets lost in transit, please get in touch with us (info@ornanbike.com) immediately and all Ornan Bike packages have been covered by insurance.

WHEEL BUILDING TECHNOLOGY:

Our carbon wheels are precise hand built.

Then trued by Holland Mechanics Pro Truer.

The perfect allocation of spoke tension in every spoke

relatively high spoke tension give many advantages:

- High radial, lateral and torsional stiffness.

- Less spoke tension loss over time.

- Longer durability.

- Less maintenance needed.

Wheel roundness tolerance: ≤0.3mm

Wheel lateral tolerance: ≤0.3mm

Wheel center tolerance: ≤0.3mm

X

X