Vacuum diffusion and pre-sealing all-in-one machine for professional lithium-ion battery research.

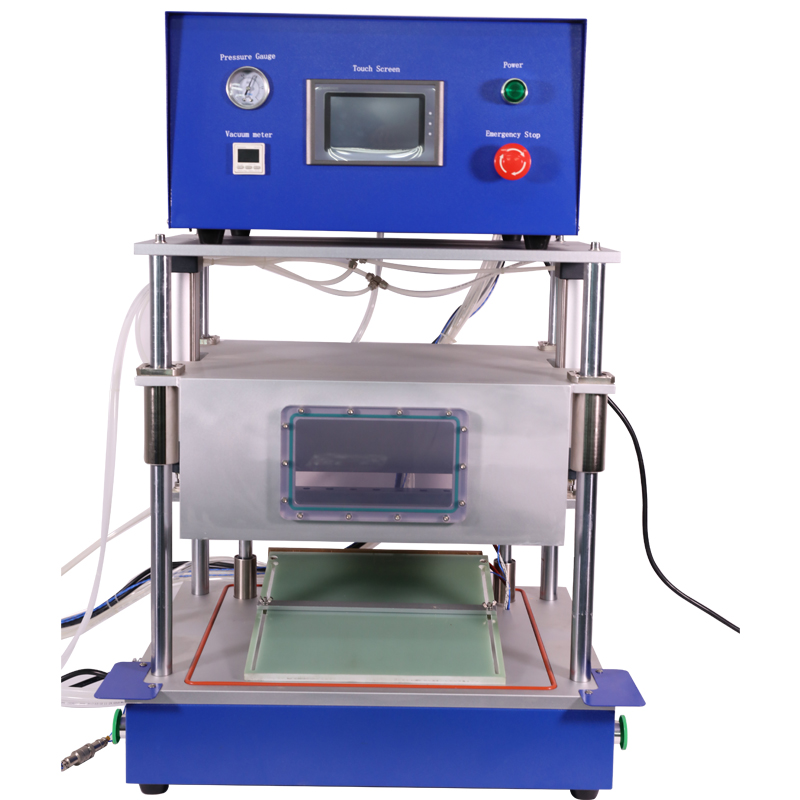

Pouch Cell Battery Electrolyte Vacuum Diffusion Chamber With pre-Sealing Function

Description

ACEY-VSS200 Vacuum diffusion and pre-sealing all-in-one machine is designed for professional lithium-ion battery research. It is mainly used to remove air from the electrolyte under vacuum conditions after the electrolyte is injected into the polymerized lithium ion battery/cylindrical battery, and finally forms a seal. It is easy to operate and suitable for all types of batteries (especially soft bag battery and cylinder battery). Unique periods of vacuum control system allows electrolyte to thoroughly saturate the electrodes to ensure the best battery charging-discharging performance.

Specification

Model

ACEY-VSS200

Power Supply

110-240 V, Single Phase 50/60Hz

Max. Power

500W

Warranty

One year limited with life time support

Compress Air

0.5-0.8Mpa

Chamber Body

12mm thick Aluminum case with observation window

Vacuum Level

Vacuum condition remains stable,

vacuum degree and vacuum circulation times can be set independently

Vacuum mode (once or twice) can be selected

Easy program setting for specific vacuum condition

Vacuum degree can up to -90Kpa~0, with good sealing,

can guarantee 1 minute air leakage is not more than 0.01 MPa

Vacuum Condition Hold Time

0 - 9999 sec, adjustable

Sealing advantage

1 Sealing Head adopts copper material, good heat transfer effect,

2 With adjust plate, Can apply to different specifications battery, and the adjusting easily

Sealing head TEM

RT-250℃, adjustable

TEM accuracy

±2℃

Heat sealing pressure

0~7Kg/cm2, adjustable

Hot Sealing Time

0~99s, adjustable

Sealing Blade

Hard type (without rubber, only for Al case sealing,

not suitable for sealing case with tab in between)

Sealing width

5mm, customized

Sealing head length

200mm

Suitable battery size(Inner size)

180*120*10mm

Dimensions

Work box: 570*420*750mm Control Unit: 460*480*250mm

Inner Chamber Size:350*285*165mm

Net weight

About 76kg

X

X