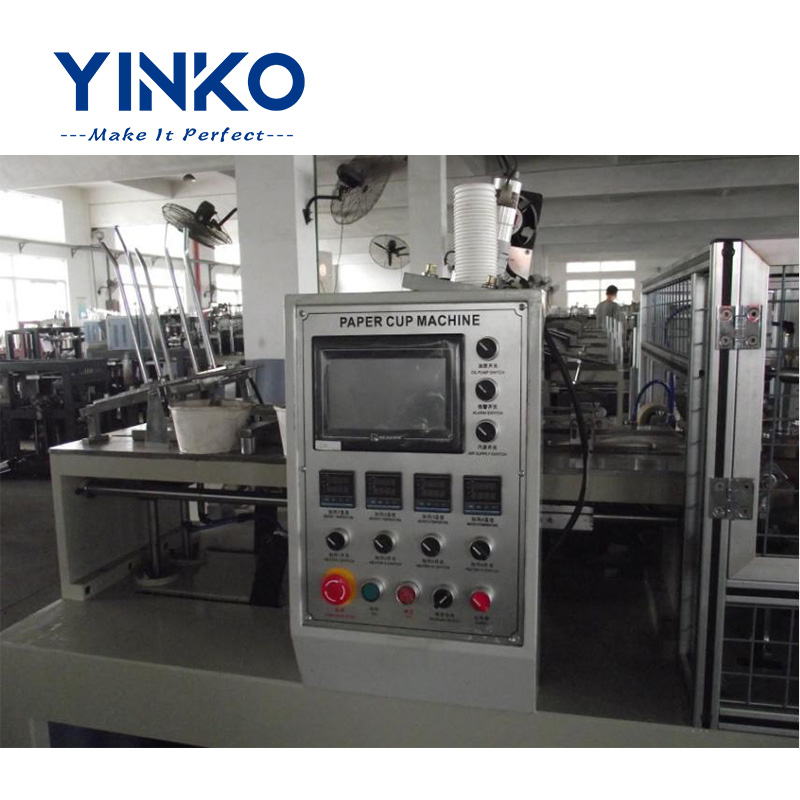

A new designed high efficiency automatic paper cup forming machine,

YK-LB120-3600A new paper cup (paper bowl) forming machine is a fully automatic paper cup (paper bowl) forming machine, through the multi-row automatic paper feeding, paper anti-backward device (to ensure accurate positioning), ultrasonic welding, robotic paper tube transfer, oil filling, bottom punching, bottom folding, preheating, knurling, unloading cup and other continuous processes, can be stable production of a variety of different specifications of paper cups,

|

|

|

|

Features

| 1.High speed production,paper cup 55-60pcs/min,paper bowl 50pcs/min; |

| 2.The bottom paper is fed by a stepping motor so that the gap between the bottom paper is controlled at about 0.1mm, which is more stable and material-saving. Meanwhile, the bottom paper is fed with the paper cylinder under the joint cooperation of the photo eye, and the bottom paper is not fed without the paper cylinder, which can avoid the waste of the bottom paper. |

| 3.The internal structure adopts a longitudinal shaft-driven gear transmission system to avoid problems such as loose chains of traditional type equipment and prevent misalignment. |

| 4.The internal structure adopts an automatic lubrication system, which reduces the friction between the parts and eliminates the maintenance work such as frequent manual oiling by customers, which greatly improves the maintenance work of the equipment. |

| 5.The machine adopts a light-controlled non-contact multi-point switch (such as at the paper frame, cup tube, bottom paper, lower cup, etc., which can be added according to customer needs) to detect abnormal work and achieve automatic fault alarm stop, to protect the machine parts from collision and improve the stability and life of the machine. |

| 6.The tube holding station adopts independent cams to drive the left and right cup clamps, with no noise when working, and stable and reliable tube holding action, which is the first technology in China. |

| 7.The machine's main motor adopts a gearmotor, eliminating the need for a separate reducer casing and motor, simplifying and stabilizing the transmission system. |

| 8.The machine frame is made of A3 iron plate, the drive shaft is made of 45# steel and the special material is made of Cr 12 (celluloid 12), and the stability of the machine is greatly improved. |

Machines details

|

|

|

|

|

|

Specifications

| Model | YK-LB120-3600A | ||

| Size of cup | 6-22oz(can be adjusted by mould) | ||

| The cup size | 12 | 16 | 22 |

| Max Height:110mm | Max.Height:139mm | Max.Height:177mm | |

| Max top diameter:105mm, Max bottom diameter:75mm | |||

| The material of paper | 180-300g/㎡(single or double pe coated paper) | ||

| Production speed | 50-60pcs/min | ||

| Power supply | 3Ph 380V 50Hz (can be customized) | ||

| Total power | 6Kw | ||

| Weight | 2500Kg | ||

| Overall dimension | 3000*1200*1580mm | ||

|

|

Paper cups

|

|

X

X